Elastic and breathable perforated medical bandage production line and making method

A production line and elastic technology, used in bandages, chemical instruments and methods, medical science, etc., can solve problems such as poor air permeability and poor elasticity, and achieve the effects of increased stretch rate, high elasticity, and large stretch rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

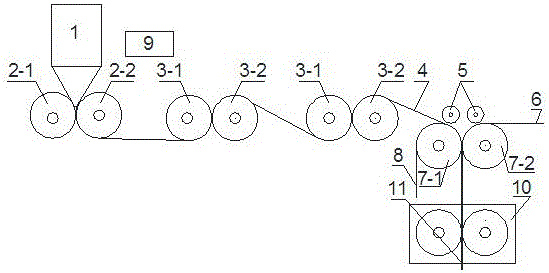

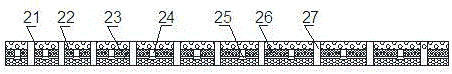

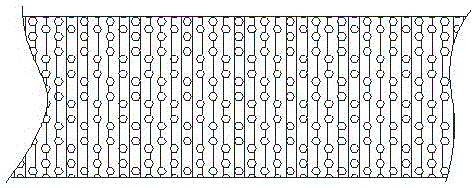

[0011] Embodiment 1: with reference to attached figure 1 . A production line for elastic and breathable perforated medical bandages, including a PLC controller 9, elastic and breathable casting die forming roller sets 2-1, 2-2 below the elastic polymer resin casting die 1, and multiple pairs of elastic breathable film stretching Roller groups 3-1 and 3-2 are distributed laterally on one side of the forming roller group of the elastic air-permeable casting die, and composite forming roller groups 7-1 and 7-2 are laterally located in multiple pairs of elastic breathable film stretching roller groups. On the side of the film stretching rollers 3-1 and 3-2, the composite nonwoven fabric punching device 10 is located on the side of the composite forming rollers 7-1 and 7-2. The elastic air-permeable casting mold forming roll group 2-1 and 2-2 are composed of a smooth roll 2-1 and a convex knife roll 2-2; the smooth roll 2-1 surface is rigid and the convex knife roll 2-2 is rigid. ...

Embodiment 2

[0012]Embodiment 2: On the basis of Example 1, the elastic air-permeable cast film forming roll set is a negative pressure perforated cast film forming roll set, and the negative pressure perforated cast film forming roll set consists of smooth roll 2-1 and The negative pressure punching roller 2-2 is formed; the roller surface of the negative pressure punching roller 2-2 is covered with negative pressure suction ports, and the negative pressure suction ports pass through the respective flow channels and the negative pressure cavity in the negative pressure punching roller. The negative pressure chamber communicates with the negative pressure suction source through the connecting pipe.

Embodiment 3

[0013] Embodiment 3: On the basis of Embodiment 1, the elastic and air-permeable cast film forming roll set is a cast film forming roll set with concave and convex points perforated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com