Production line and manufacturing method of elastic air-permeable crimped compound non-woven fabric

A non-woven, crepe-type technology, applied in the field of sanitary napkins and diapers, can solve the problems of reducing the air permeability of composite non-woven fabrics, blocking the air permeability of elastic non-woven fabrics, and being inconvenient for non-woven fabrics to be compounded, etc. The effect of stretch ratio, ensuring comfort, and increasing stretch ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

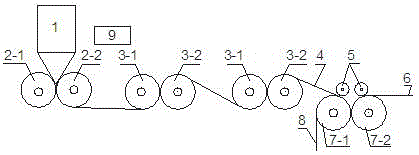

[0012] Example 1: Refer to the attached figure 1 . An elastic and breathable crepe type composite non-woven fabric production line, including a PLC controller 9, underneath the elastic polymer resin casting die 1 are elastic and breathable casting die forming roller groups 2-1 and 2-2, and multiple pairs of elastic and breathable The film stretching roller groups 3-1 and 3-2 are sequentially distributed laterally on one side of the elastic and breathable casting die forming roller group, and the composite forming roller groups 7-1 and 7-2 are laterally located in multiple pairs of elastic and breathable film stretching roller groups. End elastic breathable film stretching roll group 3-1 and 3-2 side. The elastic and air-permeable casting die forming roller sets 2-1 and 2-2 are composed of a smooth roller 2-1 and a convex knife roller 2-2; the smooth roller 2-1 surface is rigid and the convex knife roller 2-2 is convex The tooth surface of the shaped knife is in rigid contact w...

Embodiment 2

[0013] Embodiment 2: On the basis of embodiment 1, the surface of the smooth roll 2-1 is provided with a high temperature resistant anti-sticking nano coating. The elastic breathable film stretching roller group consists of smooth roller 3-1 and rubber roller 3-2 respectively coated with a layer of high temperature resistant anti-sticking nano coating. The high temperature resistant anti-sticking layer nano coating layer on the roller surface of the rubber roller 3-2 is an elastic layer. The surfaces of the composite rollers in the composite forming roller group are respectively coated with a layer of high temperature resistant anti-viscosity elastic nano coating.

Embodiment 3

[0014] Embodiment 3: On the basis of embodiment 1, the smooth roller 3-1 and the rubber roller 3-2 are equipped with an electric heating tube and a temperature sensor, and the temperature setting of the electric heating tube is controlled by the temperature collected by the temperature sensor Data and PLC controller. Multiple pairs of elastic breathable film stretching roller groups 3-1 and 3-2 middle and end roller groups are temperature control roller groups, and the smooth roller in the temperature control roller group is equipped with electric heating tubes and temperature sensors, and the temperature of the electric heating tube is set It is controlled by the temperature data collected by the temperature sensor and the PLC controller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com