High-efficiency denitrification equipment

A high-efficiency, denitrification technology, applied in the field of denitrification, can solve the problems of uneven gas temperature distribution, uneven flue gas temperature distribution, and uneven flue gas temperature distribution in the denitrification reaction area, and achieve the effect of diffuse injection area and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

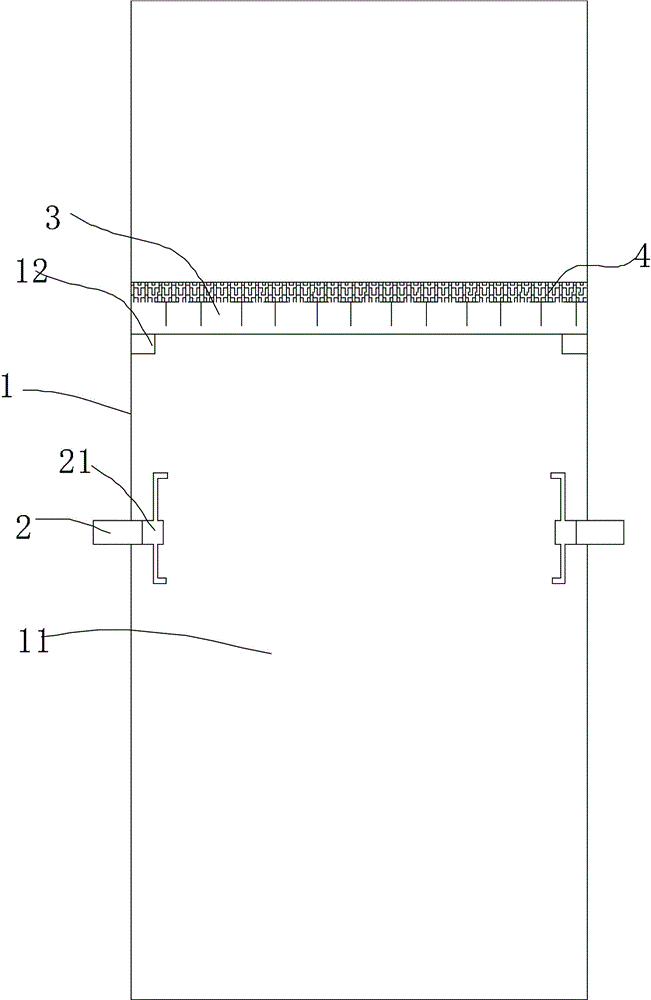

[0012] The present invention will be described in further detail below in combination with specific embodiments and accompanying drawings.

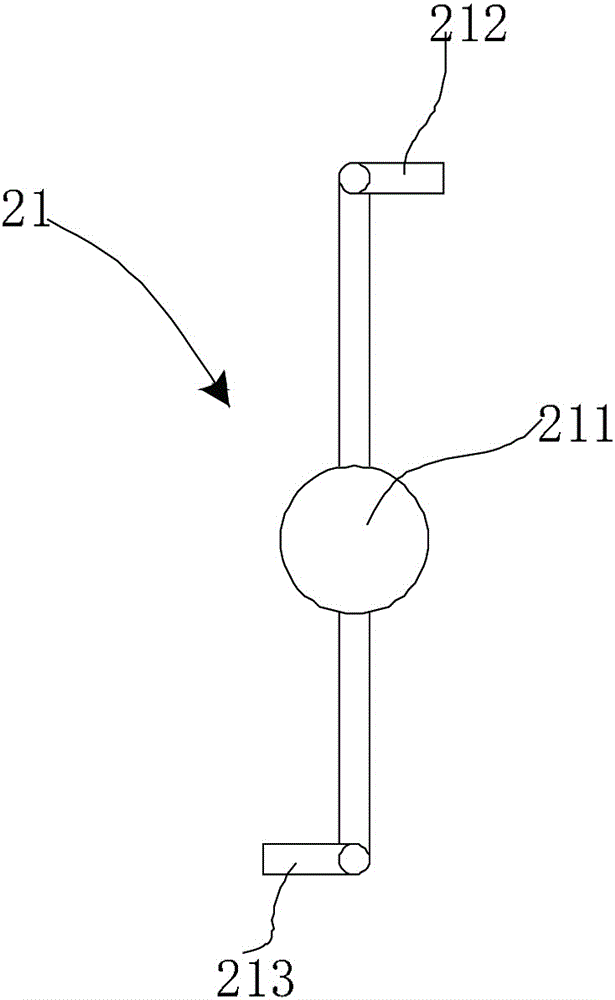

[0013] Such as Figures 1 to 2 As shown, a high-efficiency denitrification device includes a casing 1, and a channel 11 for flue gas to pass through and an injector 2 for injecting ammonia gas are arranged in the casing 1. Ejector comprises main body and the shower head 21 that is rotatably connected on the main body, and shower head 21 comprises tap 211 and nozzle 212,213, and nozzle 212,213 is welded on the tap 211, and tap 211 is rotatably connected on the trunk, and nozzle 212,213 Spray in a tangential direction.

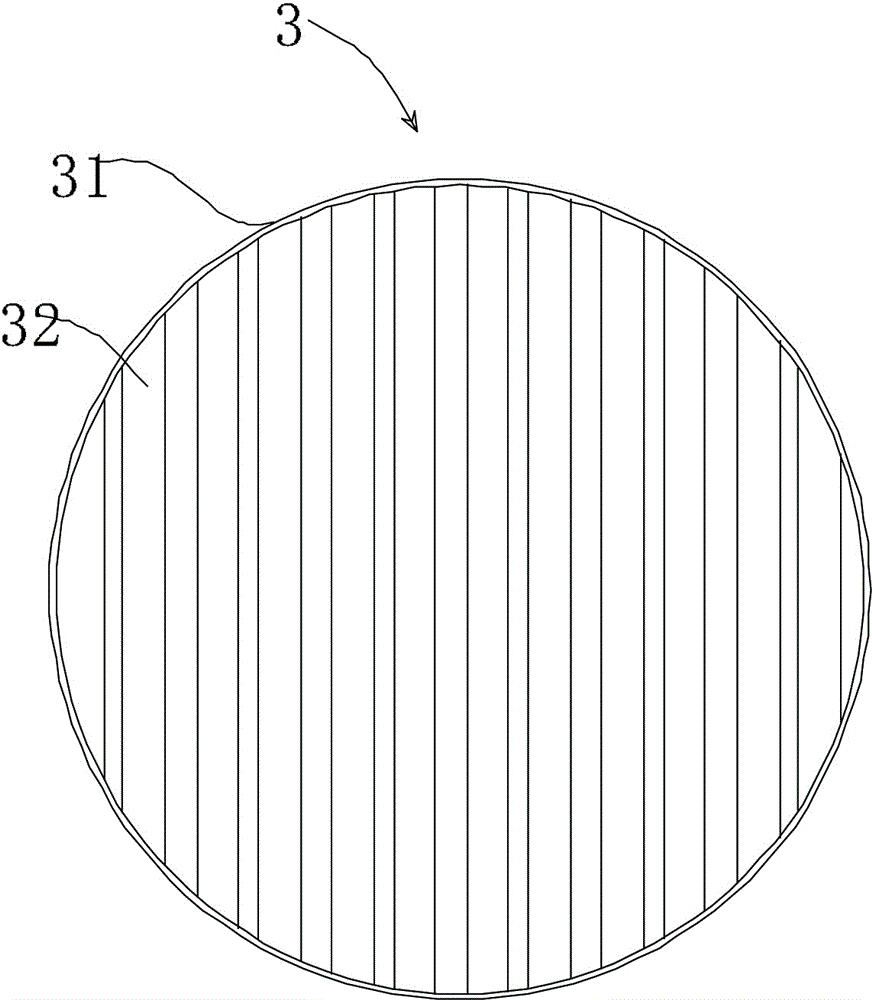

[0014] An annular retaining ring 12 is arranged at a position above the injector 2 in the channel 11, and a spoiler 3 is arranged on the retaining ring 12, and the spoiler 3 includes a fixed plate 31 and a T-shaped plate 32 made of metal, The fixing plate 31 is an annular baffle plate, and the T-shaped plate includes two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com