Lump mineral crushing and primary screening device

A screening device and mineral technology, applied in the fields of sieving, solid separation, grain processing, etc., can solve the problems of reducing ore quality, increasing workload, overloading screening machine, etc., achieving obvious screening effect, preventing overload operation, The effect of preventing concentrated feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

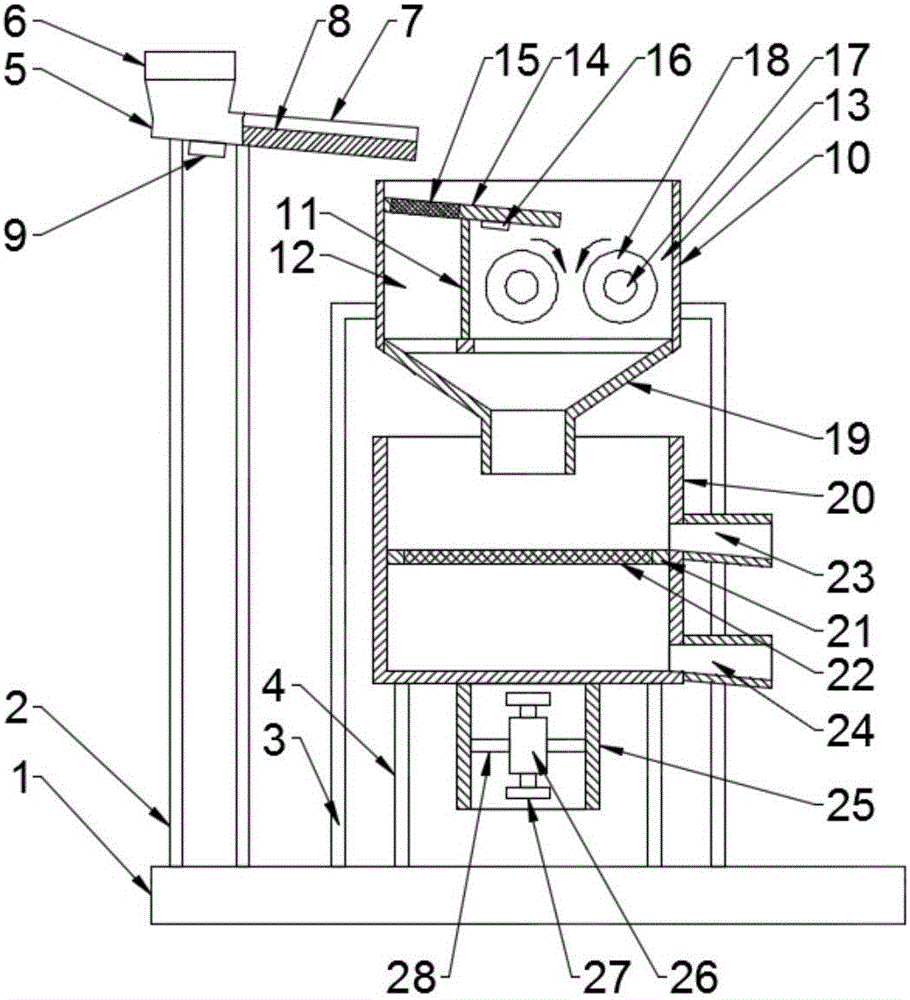

[0016] see figure 1 , a bulk mineral crushing primary screening device, including a base 1, two first pillars 2, two second pillars 3 and two third pillars 4 are arranged on the top of the base 1, and the two first pillars The three pillars 4 are symmetrically arranged on the middle part of the top end surface of the base 1, the two second pillars 3 are symmetrically arranged on the left and right sides of the two third pillars 4, and the two first pillars 2 are arranged symmetrically. On one side of the second pillar 3, the top ends of the two third pillars 4 are fixedly connected to the screening box 20, and the top ends of the two second pillars 3 are fixedly connected to the crushing box 10, and the crushing box 10 is arranged on the screen Directly above the sub-box 20, the screening box 20 is a cylindrical box structure design with an open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com