Chemical slurry treatment system

A technology for processing system and slurry, applied in the field of medicine, can solve the problems of insufficient compact structure and poor pulverization effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described in conjunction with the following examples.

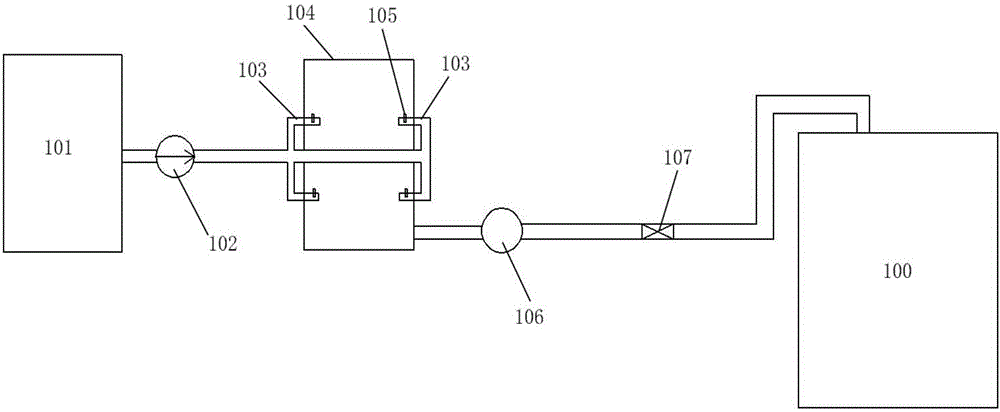

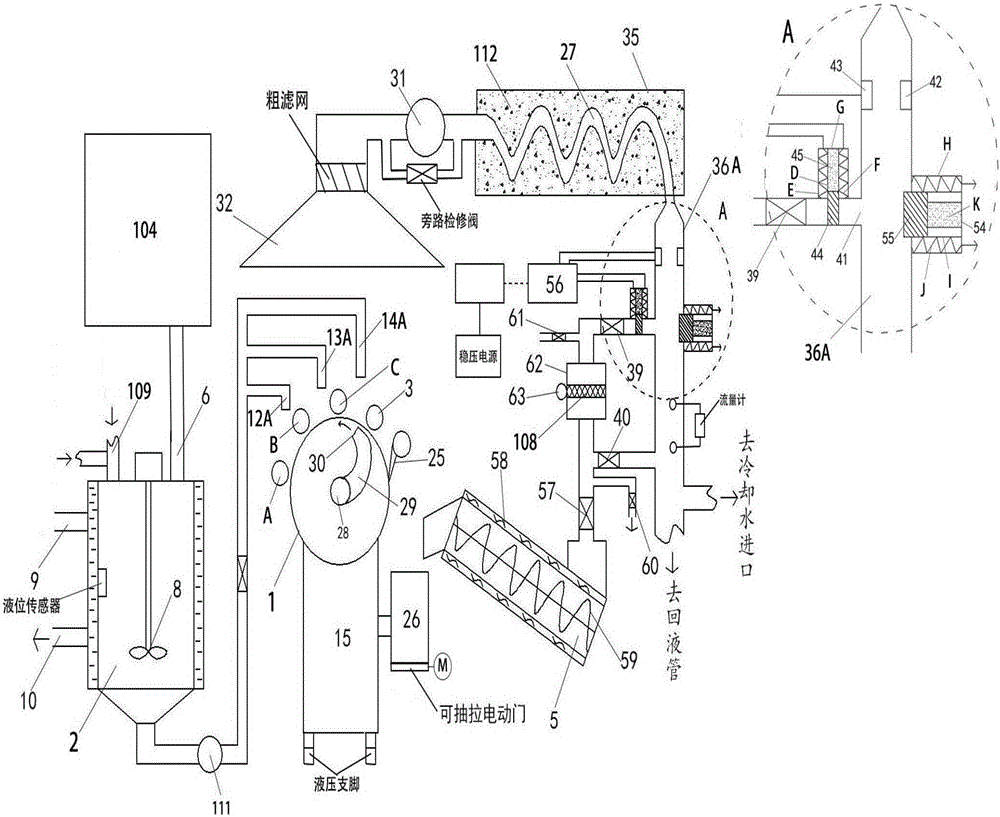

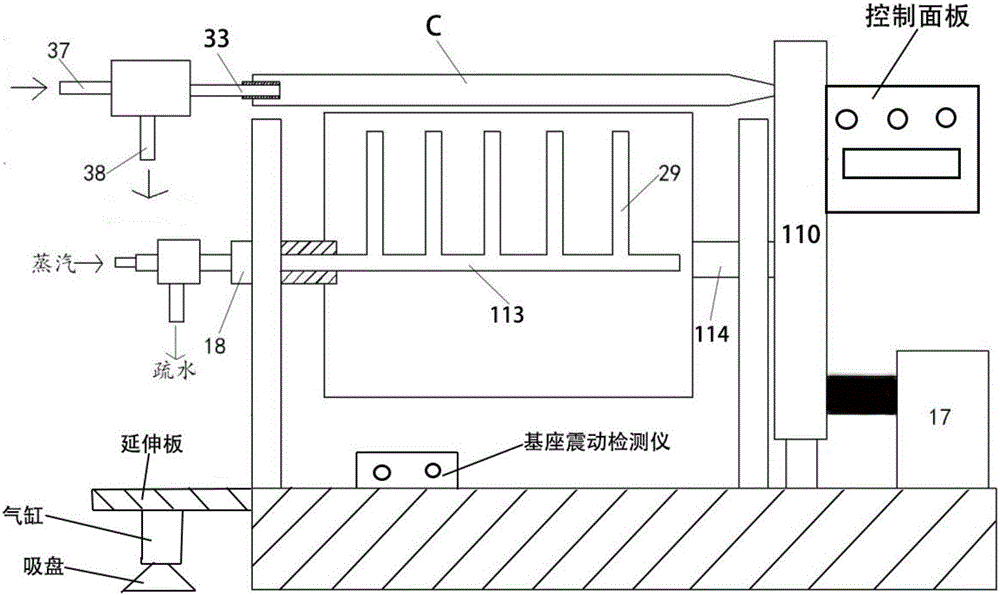

[0014] Such as figure 1 A kind of medicine slurry processing system shown, comprises the slurry tank 201, ultrasonic pulverization device and drug drying device 100 that are connected in sequence; 103 is divided into two layers, surrounding the pulverizing device casing 104 of the ultrasonic pulverizing device, spraying slurry into the pulverizing device casing 104, and the ultrasonic nozzle 103 achieves the purpose of pulverizing through the ultrasonic vibrating plate 105 arranged in the nozzle; the pulverizing device The slurry at the bottom of the casing 104 is sent to the slurry inlet pipe 6 of the medicine drying device 100 through the output pump 106 .

[0015] The present invention generates ultrasonic waves by arranging two layers of ultrasonic vibrating plates, and utilizes the cavitation effect, shearing effect and micro-jet action of ultrasonic waves to further pulverize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com