Tea-leaf drying and screening device

A screening device and tea technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of difficult heat recycling, poor tea drying effect, interference with tea drying, etc., and the drying time is easy to be blocked Control, the degree of drying is easy to control, and the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below by specific embodiments:

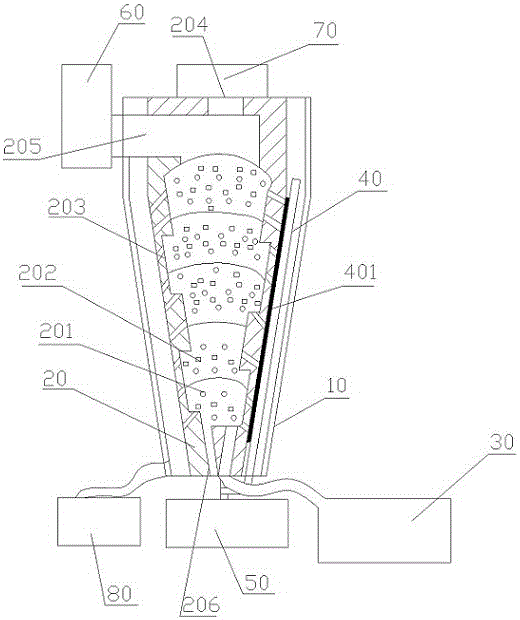

[0015] Reference numerals in the drawings in the description include: casing 10 , drying cylinder 20 , through holes 201 , protrusions 202 , guide grooves 203 , exhaust holes 204 , material inlet 205 , material outlet 206 , hot air generator 30 , lever 40 , rubber pad 401 , motor 50 , accelerator 60 , dehumidifier 70 , negative pressure collection device 80 .

[0016] The example is basically as attached figure 1 Shown: a tea drying and screening device, including a casing 10, a drying cylinder 20, a hot air generator 30, a lever 40, a motor 50, an accelerator 60, a dehumidifier 70 and a negative pressure collection device 80. The drying cylinder 20 is fixedly installed in the casing 10, the hot air generator 30 is fixedly installed at the lower end of the drying cylinder 20, and the hot air generator 30 is fixedly connected with the lower end of the casing 10, and the shape of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com