A kind of preparation method of low-temperature ferritic nodular cast iron attached casting test block

A technology of nodular cast iron and ferrite, which is applied in the field of low-temperature ferritic nodular cast iron attached casting test block preparation, can solve the problems of non-compact structure and shrinkage porosity, and achieve the effect of compact structure and complete and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

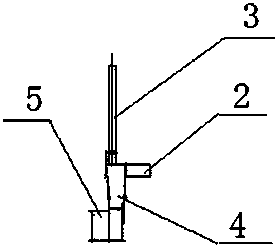

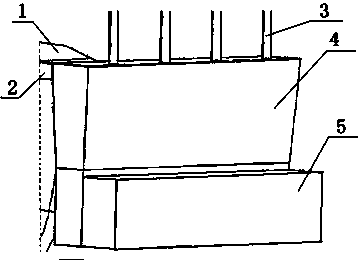

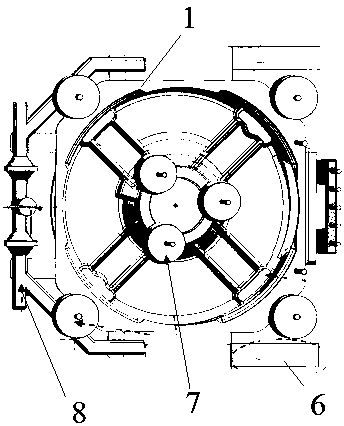

[0023] Such as figure 1 , 2 , 3, 4 shown, a kind of low-temperature ferritic nodular cast iron attached casting test block preparation method, use gating system 8, casting mould, attached casting test block mold 4; The uppermost end of described attached casting test block mold 4 passes The test block sprue connecting channel 2 is connected with the casting 1, an overflow channel 3 is established above the attached test block mold 4, and a cold iron 5 is placed at the performance place 9 of the attached test block mold 4 on the lower side of the attached cast test block mold. Casting test block mold 4 is placed vertically.

[0024] The attached casting test block mold 4 is placed vertically, and the test block gate connecting channel 2 is located at the uppermost end of the attached casting test block mold 4. This design is conducive to the sufficient flow of molten iron into the attached casting test block mold 4, and overcomes the Insufficient fluidity of molten iron leads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com