Patents

Literature

32results about How to "Reduces shrinkage tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-wear-resistance long-life ductile iron and method of producing lower cylinder with ductile iron

ActiveCN106834901AImprove wear resistanceExtended service lifeFoundry mouldsFurnace typesHigh wear resistanceDuctile iron

The invention discloses high-wear-resistance long-life ductile iron, comprising, by weight, 3.80-3.88% of C, 2.20-2.30% of Si, 0.55-0.65% of Mn, < / =0.020% of P, < / =0.010% of S, 0.45-0.55% of Cu, 0.30-0.40% of Mo, 0.0040-0.0060% of La, 0.035-0.045% of Mg, and the balance of iron and unavoidable impurity. The invention is intended to provide the high-wear-resistance long-life ductile iron that has high rigidity and fatigue strength and has improved tensile strength and plasticity, and a method of producing a lower cylinder with the ductile iron.

Owner:GUANGDONG ZHONGTIAN CHUANGZHAN DUCTILE IRON CO LTD

Vermicular graphite cast iron single cylinder diesel engine body with high vermicular graphite rate and preparation method thereof

The invention relates to a single cylinder diesel engine body and particularly relates to a vermicular graphite cast iron single cylinder diesel engine body with high vermicular graphite rate. The single cylinder diesel engine body comprises the following chemical components in percentage by mass: 3.5-3.8% of C, 2.1-2.6% of Si, 0.5-0.8% of Mn, less than 0.08% of P, less than 0.03% of S and the balance of iron and inevitable impurities. The single cylinder diesel engine body provided by the invention has the characteristics of less inclination of shrinkage cavity and shrinkage porosity and long service life. The invention further provides a preparation method of the single cylinder diesel engine body, which is reasonable in process.

Owner:SHANDONG YUANTONG MASCH CO LTD

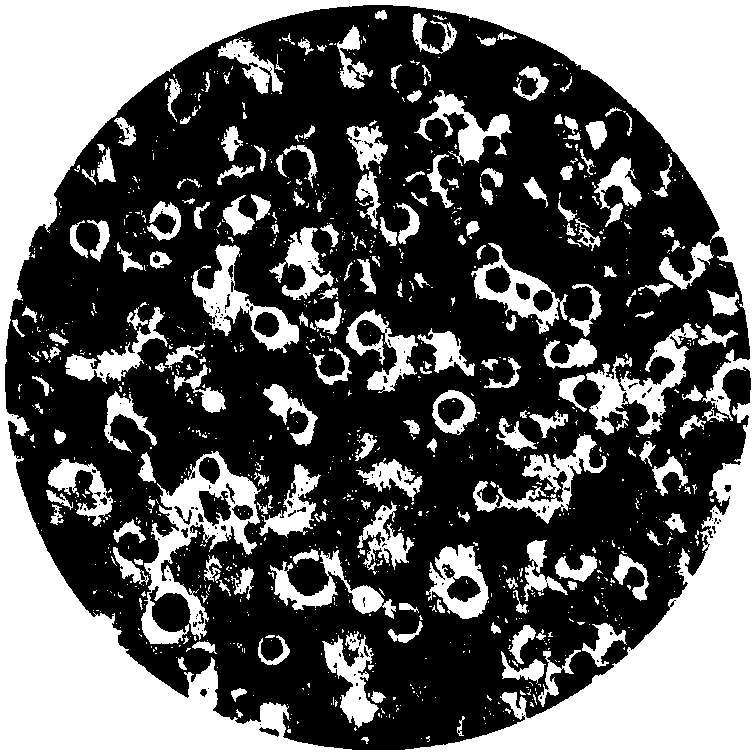

Special nodulizer for low-temperature impact resistant and high-ductility nodular cast iron and method for preparing special nodulizer

The invention discloses a special nodulizer for low-temperature impact resistant and high-ductility nodular cast iron and a method for preparing the special nodulizer. Components of the special nodulizer include, in mass percent, 0.5-1.5% of RE, 4-7% of Mg, 42-49% of Si, 0.5-3% of Ca, less than or equal to 0.5% of Al, less than 0.4% of MgO and the balance Fe. The special nodulizer requires high purity, has the stable components, and is small in segregation, strict in granular control and reasonable in distribution. When in use, the special nodulizer has the advantages that nodularity is higher than 85% and recession resistance is high when Mg residues in castings are controlled within the low limit of 0.036-0.040%, Mg absorption rate is high, addition of the special nodulizer is decreased by 20-30% as compared with that of a general nodulizer, less slag is generated in nodulizing reaction, slag inclusion defects of the castings are obviously decreased, magnetic particle inspection passing rate is obviously increased, the number of graphite nodules ranges from 120 to 150, the tendency of shrinkage porosity of the castings is obviously decreased, and ultrasonic inspection passing rate is obviously increased. The content of rare earth in a traditional common nodulizer generally ranges from 2% to 6%, the content of rare earth in the special nodulizer ranges from 0.5% to 1.5%, and previous rare earth resources are saved.

Owner:JIANGSU YAFENG ALLOY MATERIAL

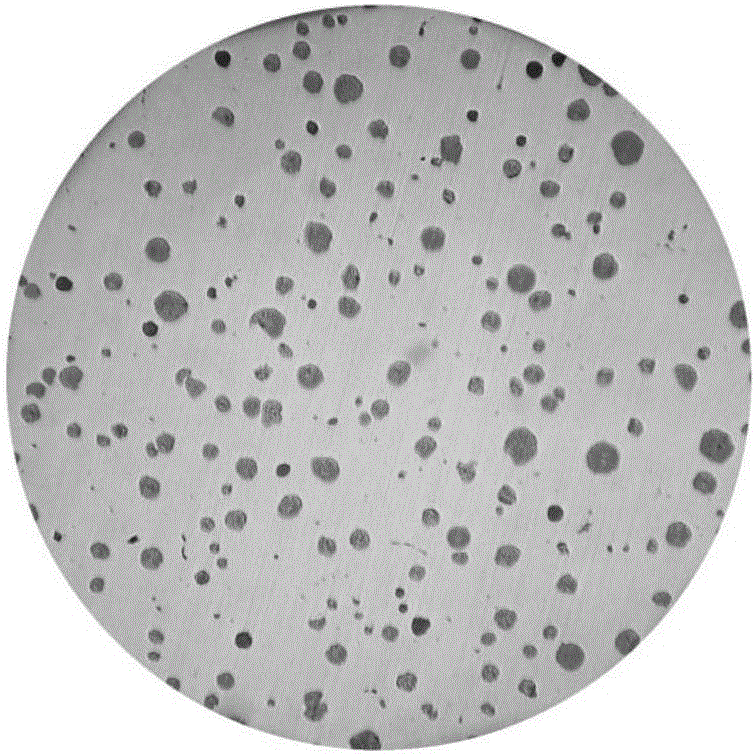

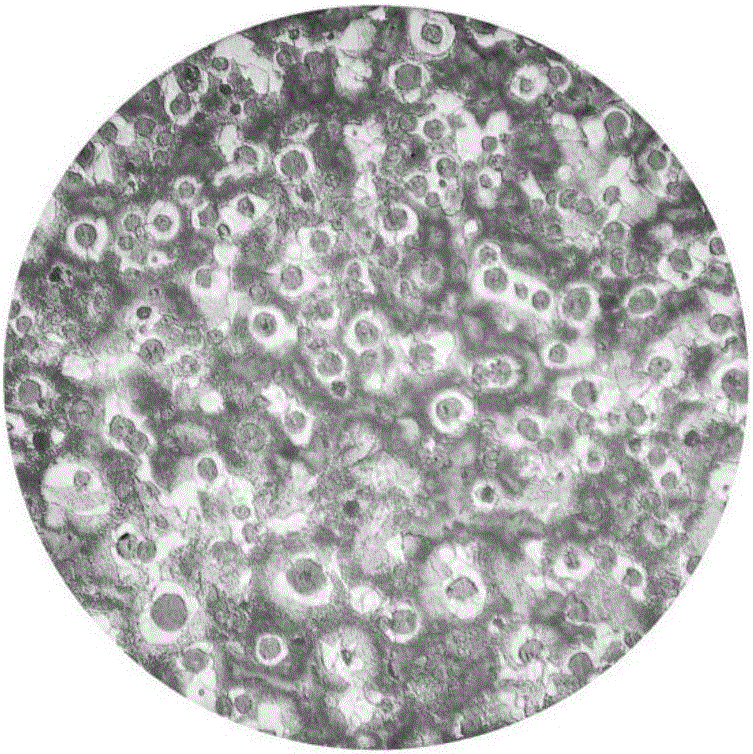

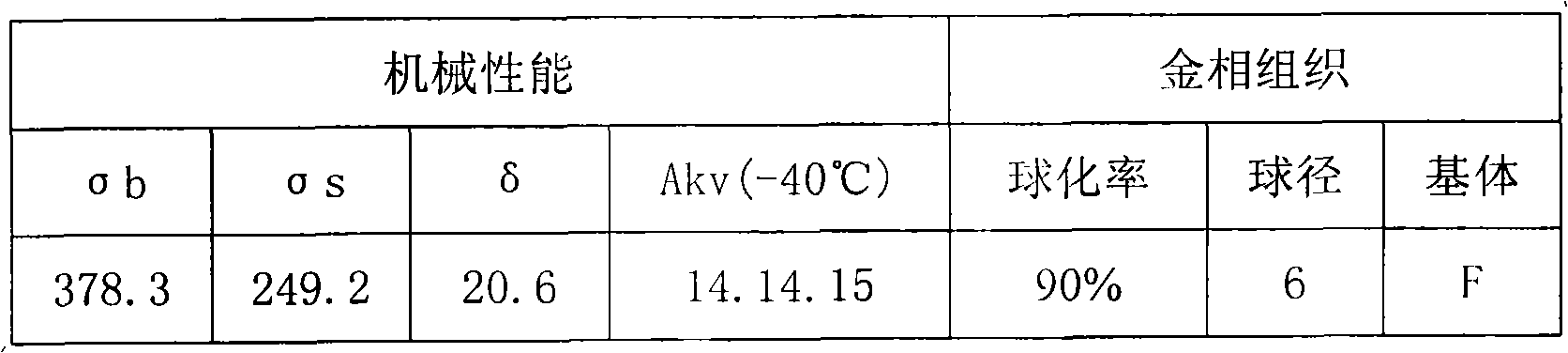

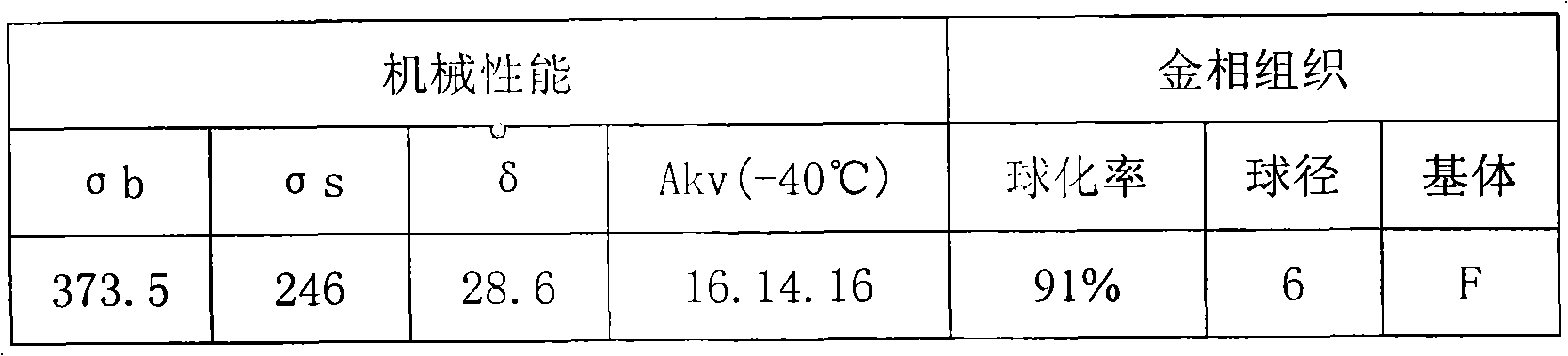

Low-temperature ferrite ductile cast iron auxiliary casting test block preparation method

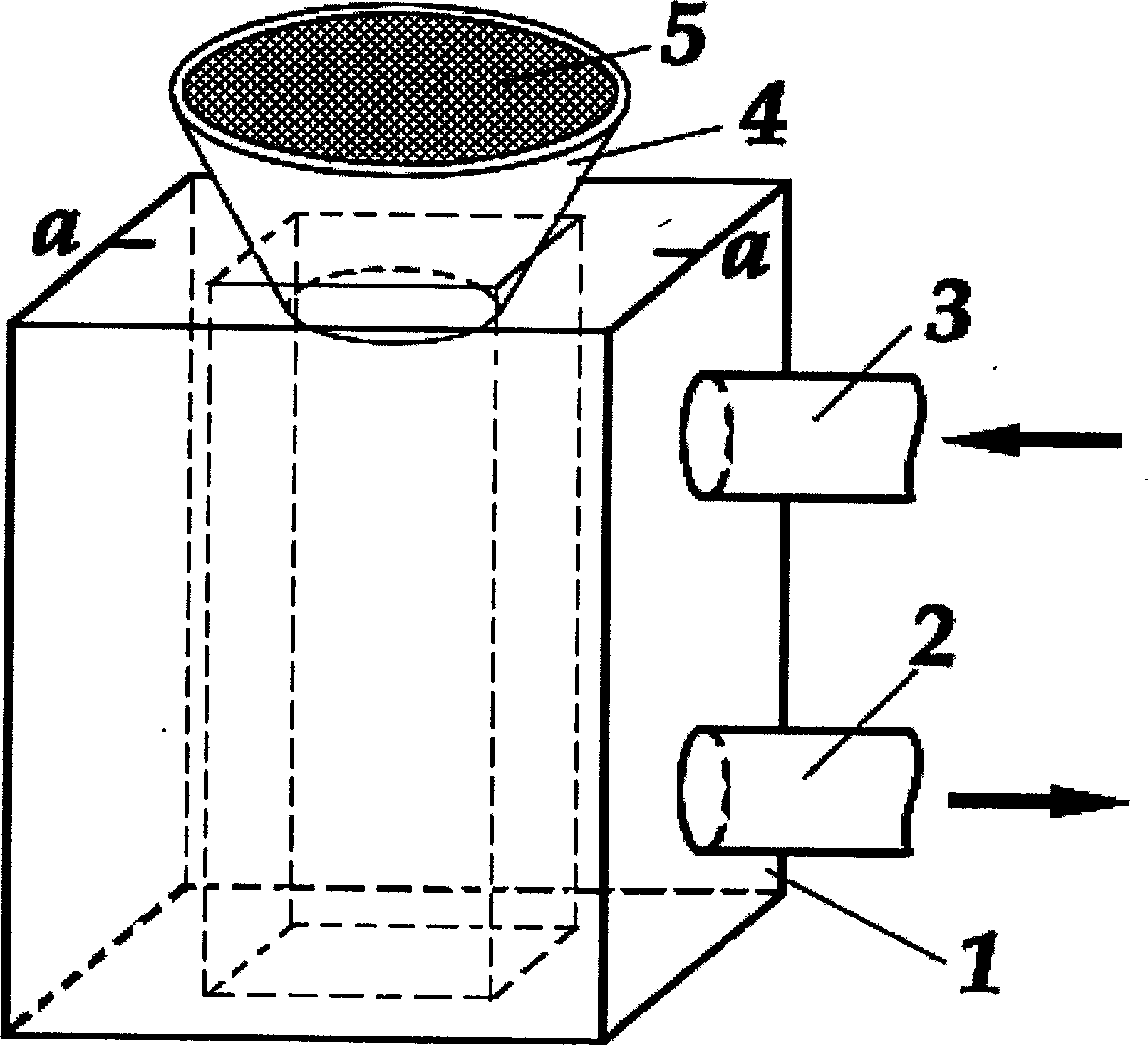

ActiveCN106424572ADense tissueComplete and uniform performancePreparing sample for investigationFoundry mouldsDuctile ironCasting mold

The invention relates to a casting process, in particular to a low-temperature ferrite ductile cast iron auxiliary casting test block preparation method. In order to solve the problem of totally consistent performances of an auxiliary casting test block and a casting, the invention proposes the low-temperature ferrite ductile cast iron auxiliary casting test block preparation method. The low-temperature ferrite ductile cast iron auxiliary casting test block preparation method uses a pouring system, a casting mold and an auxiliary casting test block mold; the uppermost end of the auxiliary casting test block mold is connected with the casting through a test block sprue connecting way; an overflow way is formed above the auxiliary casting test block mold; cold iron is put in the auxiliary casting test block performance taking place on the lower side of the auxiliary casting test block mold; and the auxiliary casting test block mold is vertically placed. Through transformation, a prepared auxiliary casting test block and a single casting Y-shaped test block have similar performances to reflect real casting performances.

Owner:ASIMCO INT CASTING CO LTD SHANXI

Nodular cast iron manhole cover casting method for preventing cold shut defects

The invention discloses a nodular cast iron manhole cover casting method for preventing cold shut defects. Molten iron component selection is controlled, microelements exceeding general standards arenot allowed, reasonable nodulizing agents and nucleating agents are added, lanthanum can eliminate graphite deterioration and graphite floatation, the tendency of blooming graphite aggregation is decreased, the number of graphite nodules can be increased, nodulizing rate is increased, shrinkage porosity tendency is decreased, high-quality nodular cast iron liquid is provided, and the cold shut defects of a formed cast iron manhole cover are decreased. By strictly controlling casting temperature and casting modes, the probability of casting defects such as sand burning, shrinkage and deformation is reduced, and each casting mould is uniformly filled with molten iron. The cold shut defects are prevented by the aid of component control, casting temperature and mode control and the like in thecasting process, the nodular cast iron manhole cover is excellent in quality and mechanical property and worthy of popularization, and the process is conveniently controlled.

Owner:安徽大来机械制造有限公司

Carbon and silicon inoculant

The invention relates to a carbon-silicon inoculant. The compositions of the inoculant in percentage by weight are 25 to 35 percent of carbon, 30 to 60 percent of silicon, less than 0.3 percent of calcium, less than 0.3 percent of aluminum, and the balance being iron. The granularity of the carbon-silicon inoculant is between 0.1 and 3 millimeters. The carbon-silicon inoculant has the advantages as follows: firstly, the carbon-silicon inoculant can effectively prolong the time of graphited fade; secondly, the carbon-silicon inoculant can obviously increase the hardness of cast, eliminate alloyed white of the cast, improve the form and the distribution state of graphite in thin-wall cast, and lessen the difference of crystal phase structures on positions with different thicknesses; and thirdly, the carbon-silicon inoculant reduces dispersed shrinkage tendency of the cast and improves the compactness of the cast. Moreover, the carbon-silicon inoculant can improve the performances of the cold and thermal fatigue resistance and the mechanical fatigue resistance of movable cast.

Owner:大连核心铸造技术工程研究所

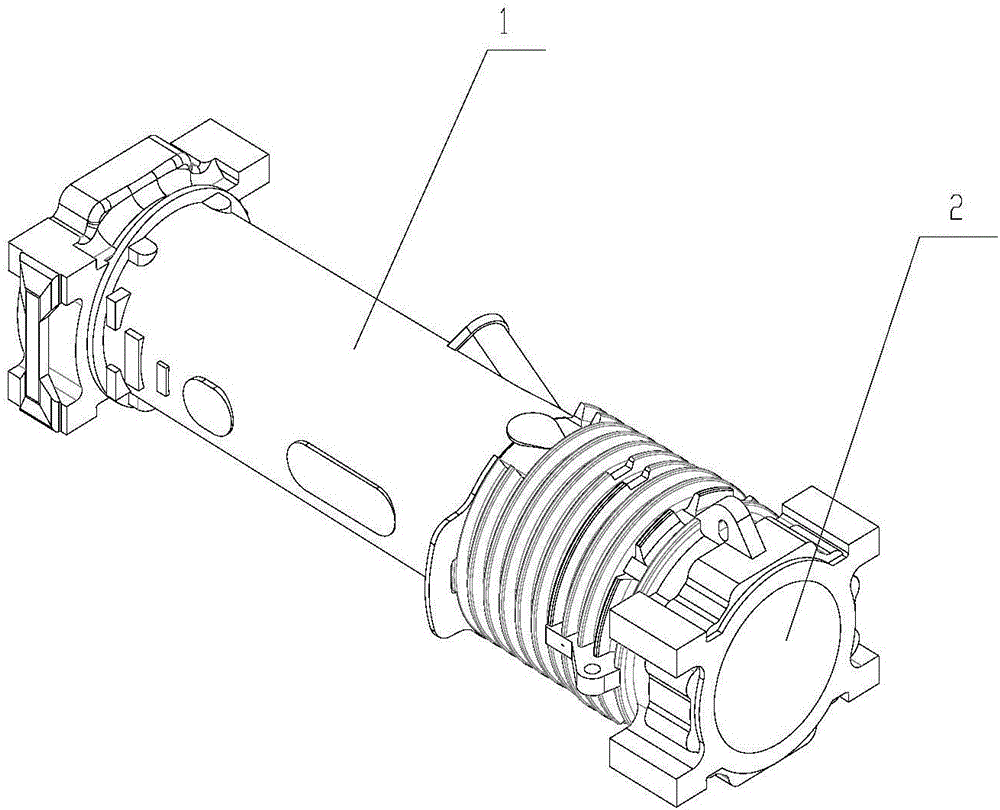

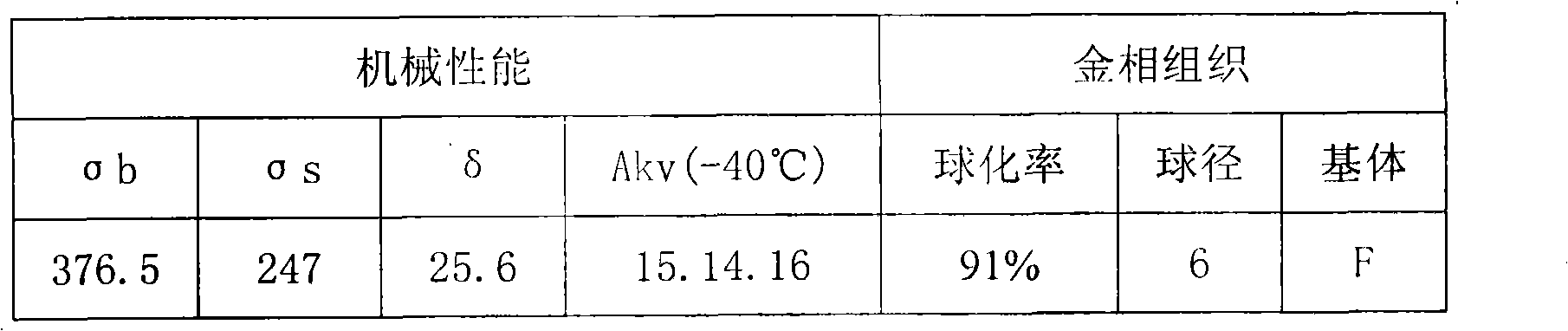

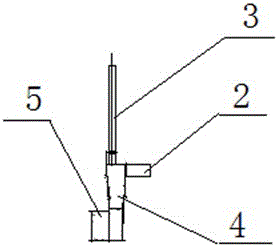

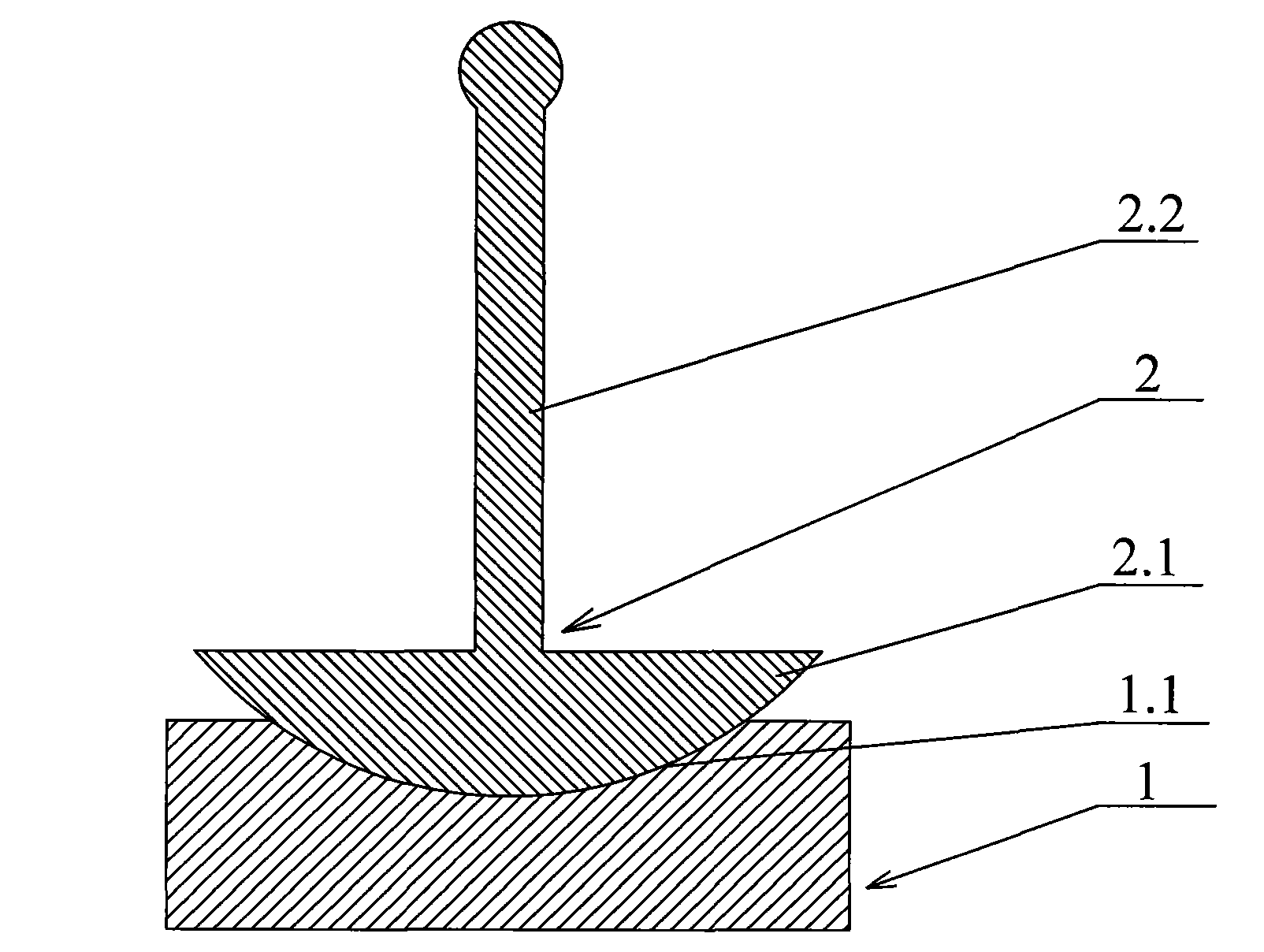

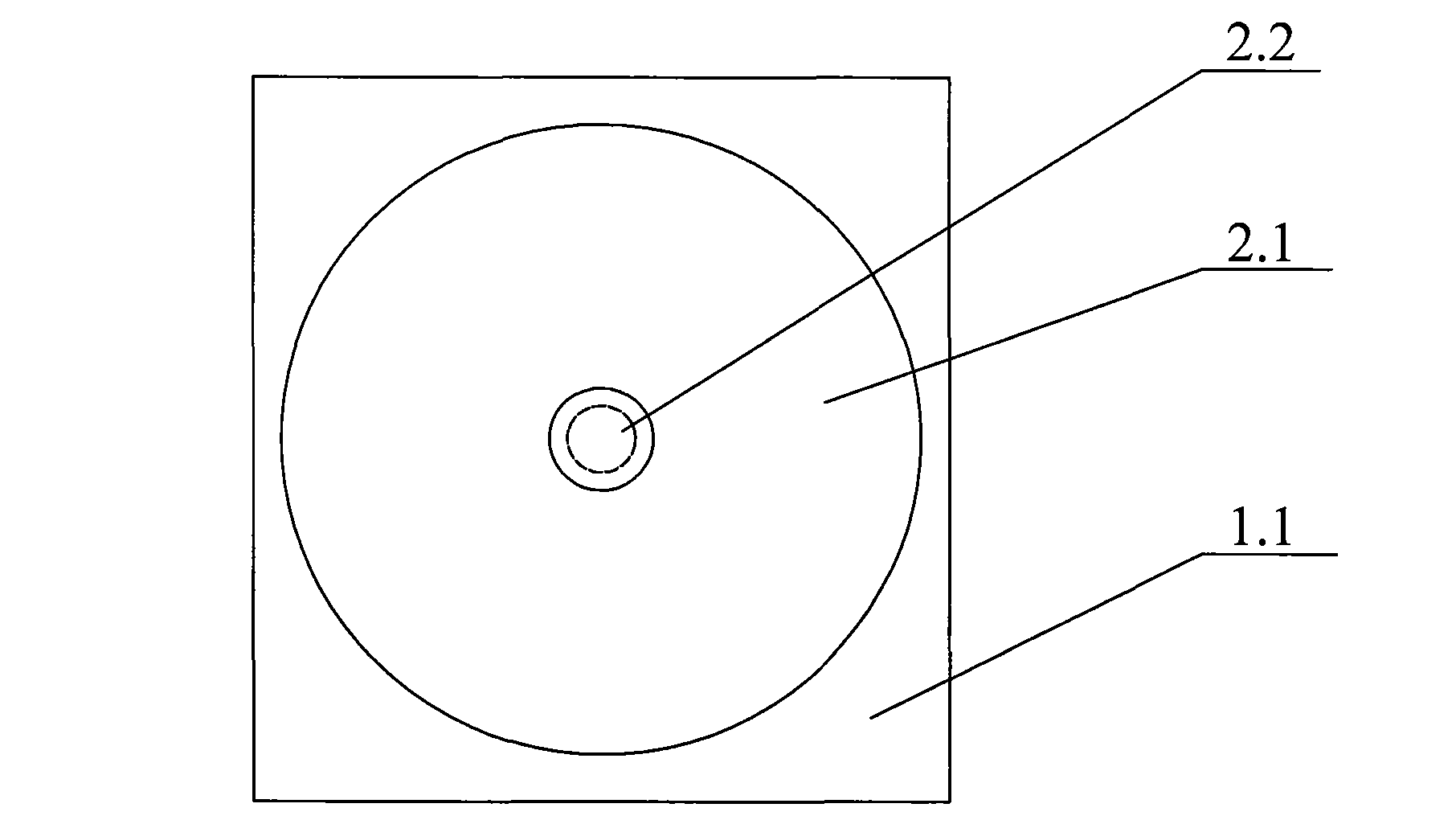

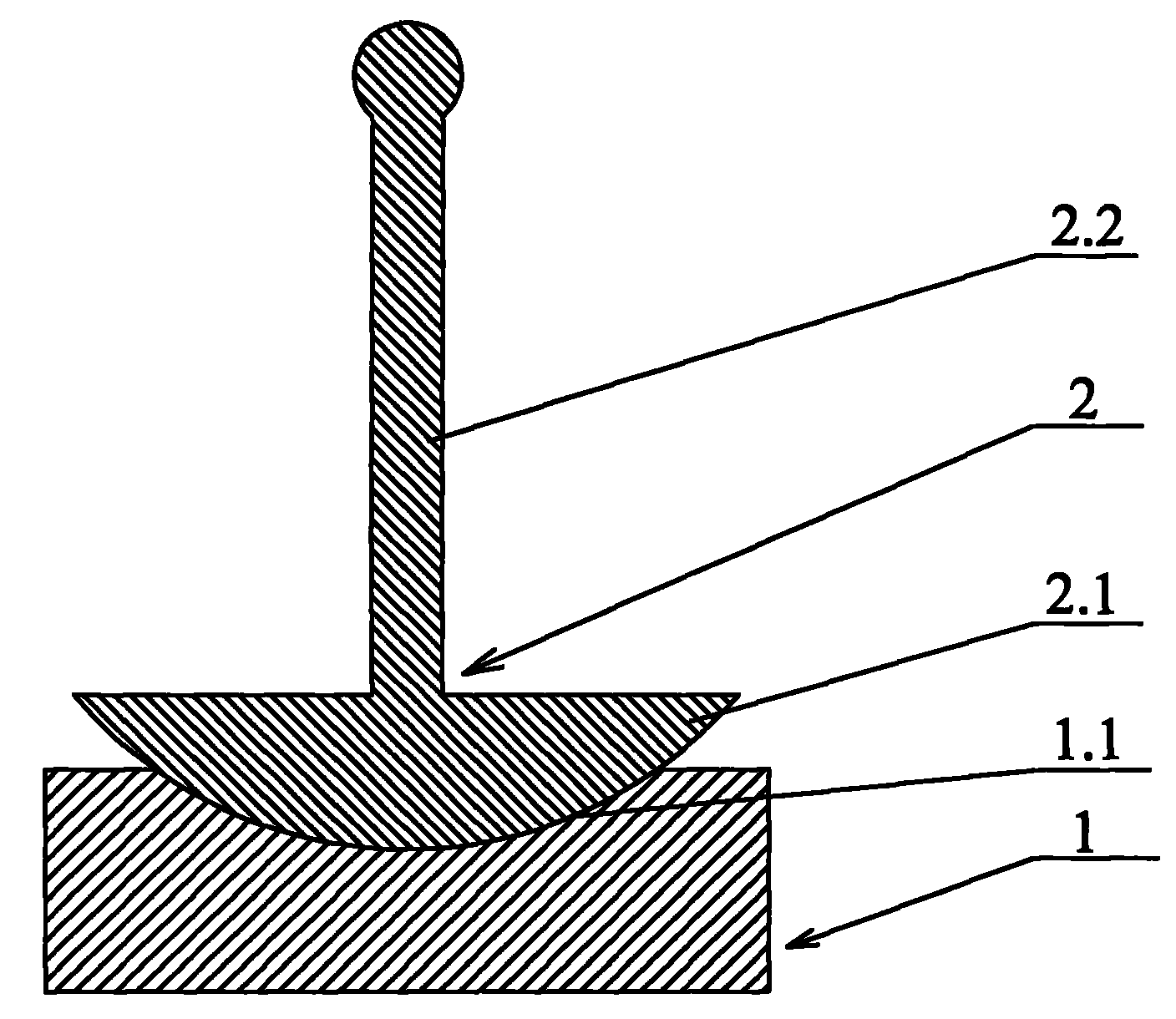

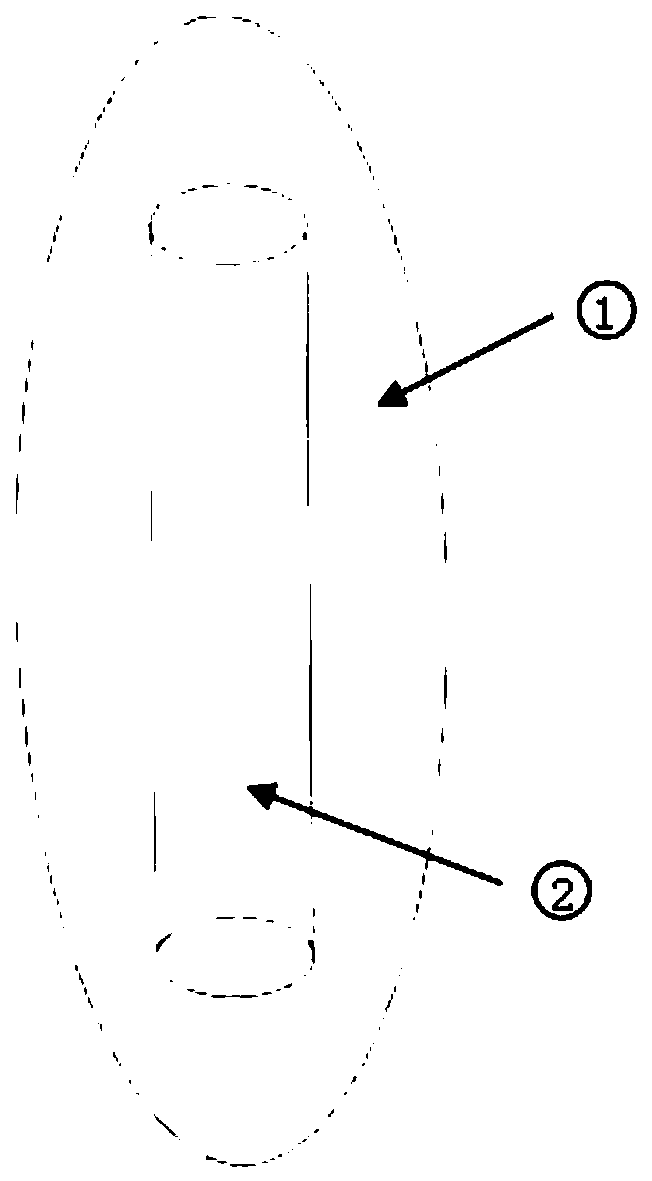

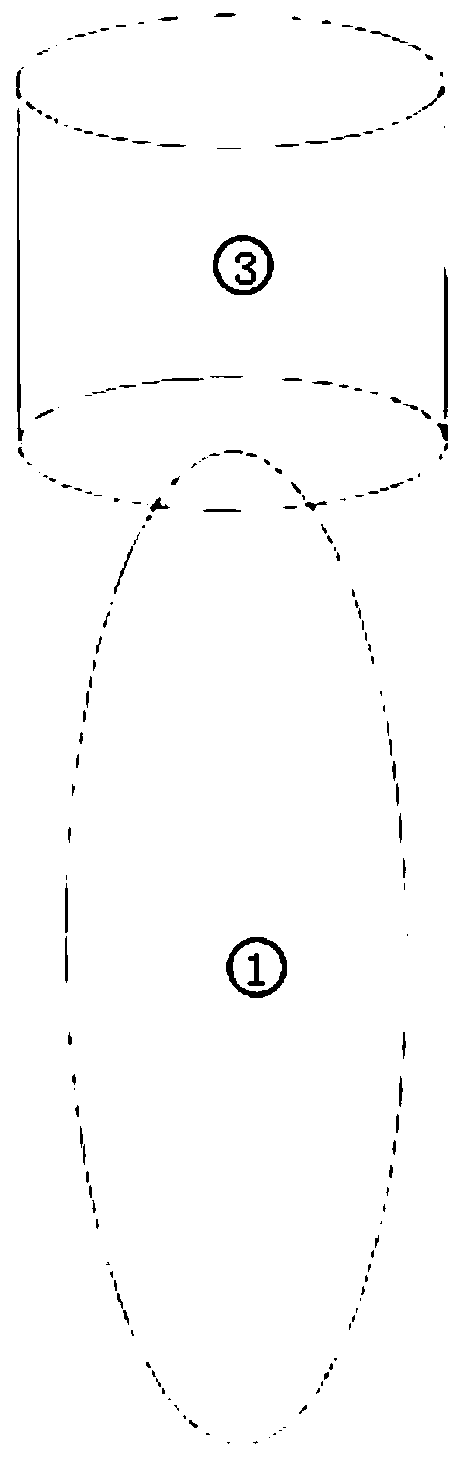

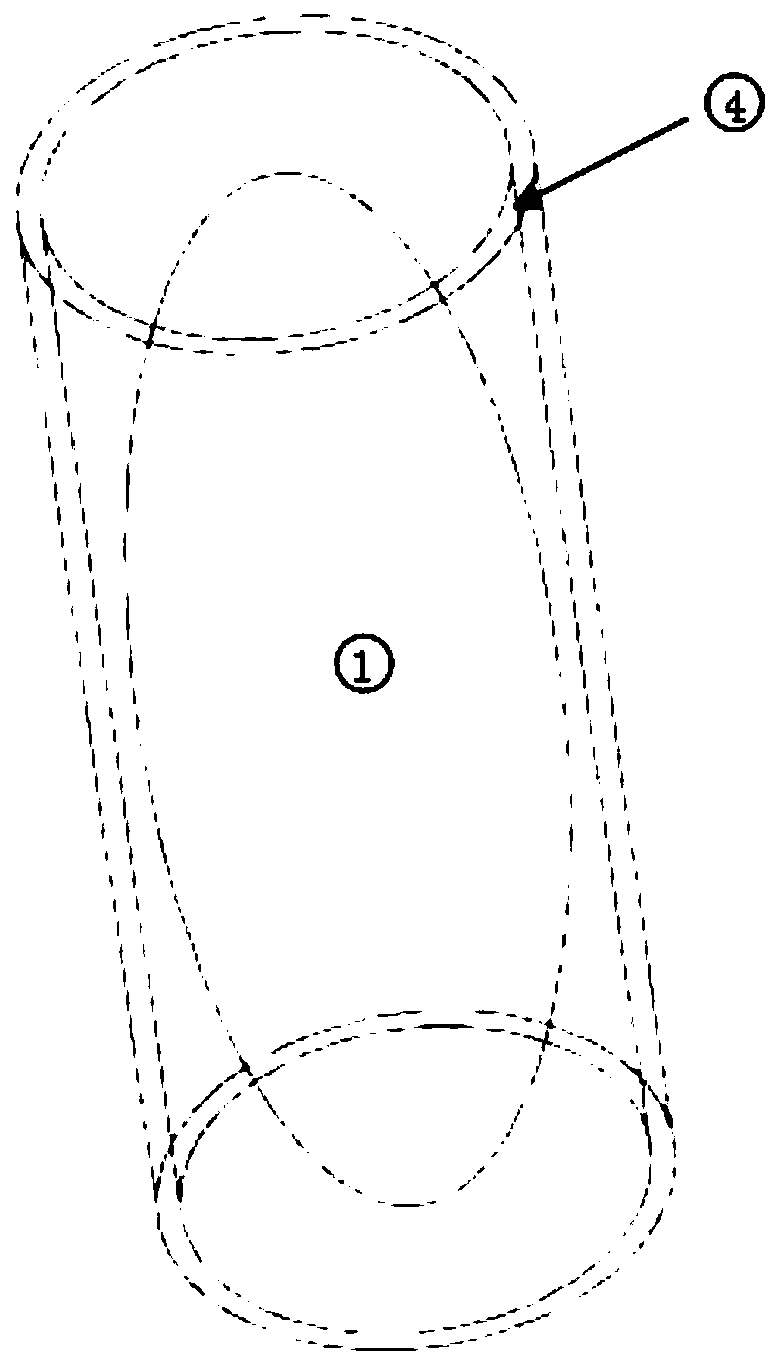

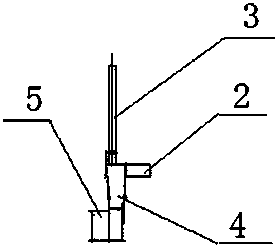

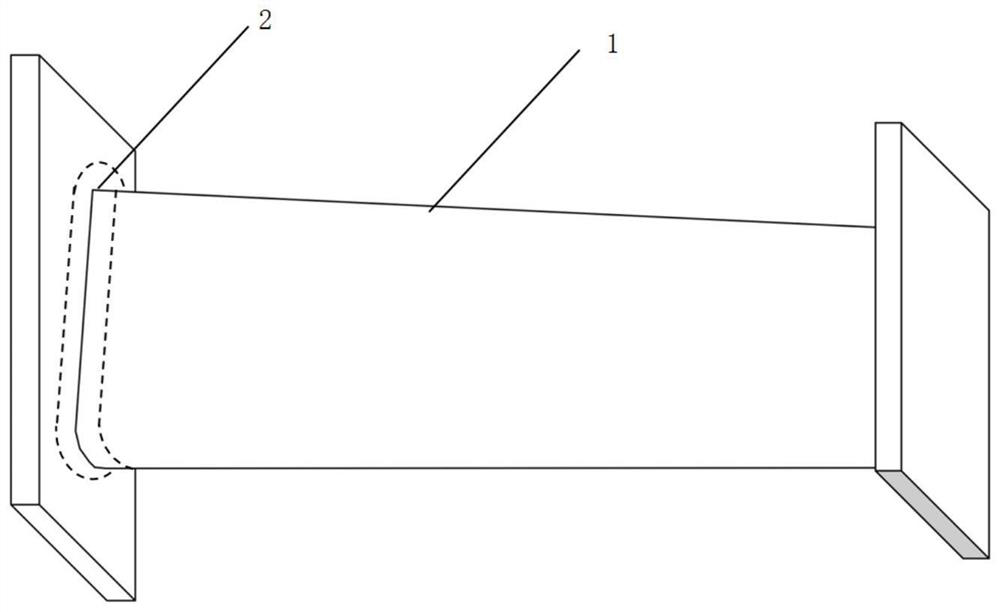

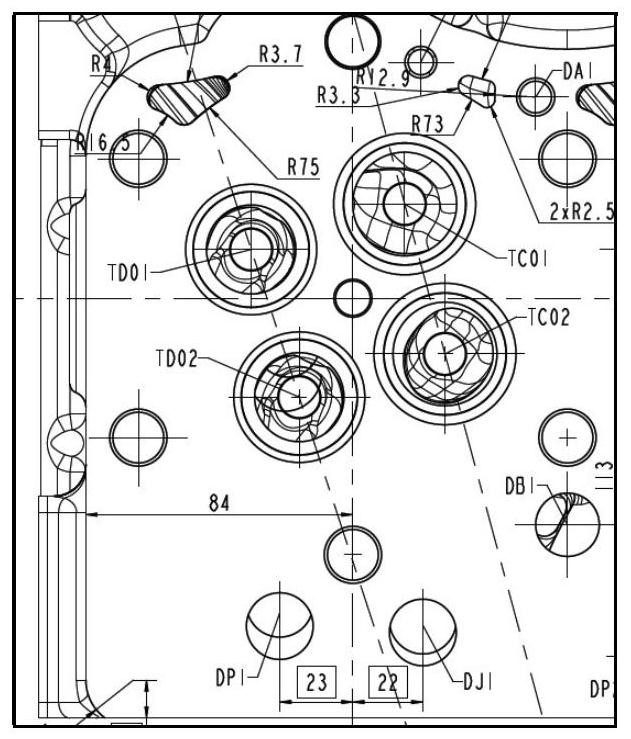

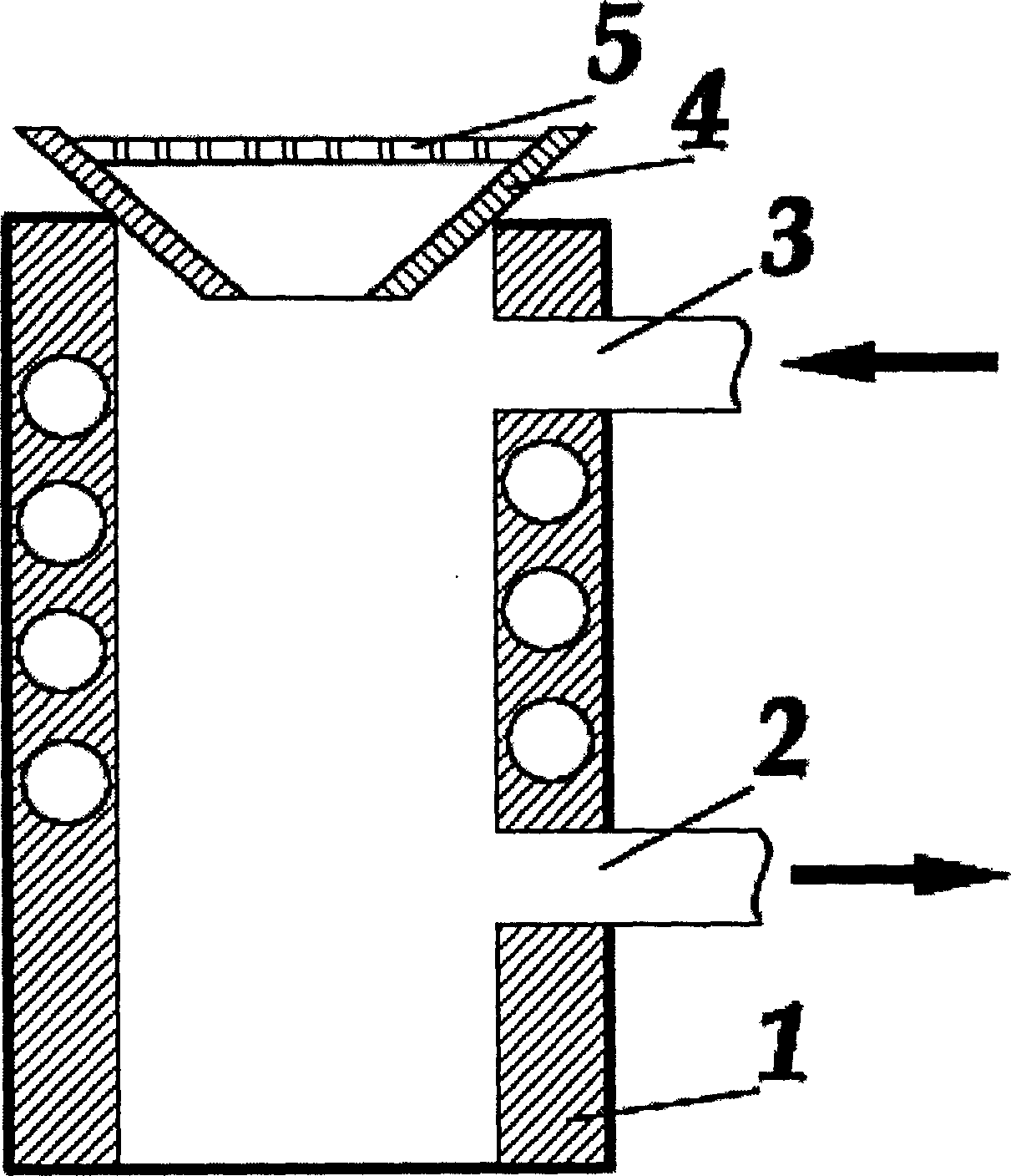

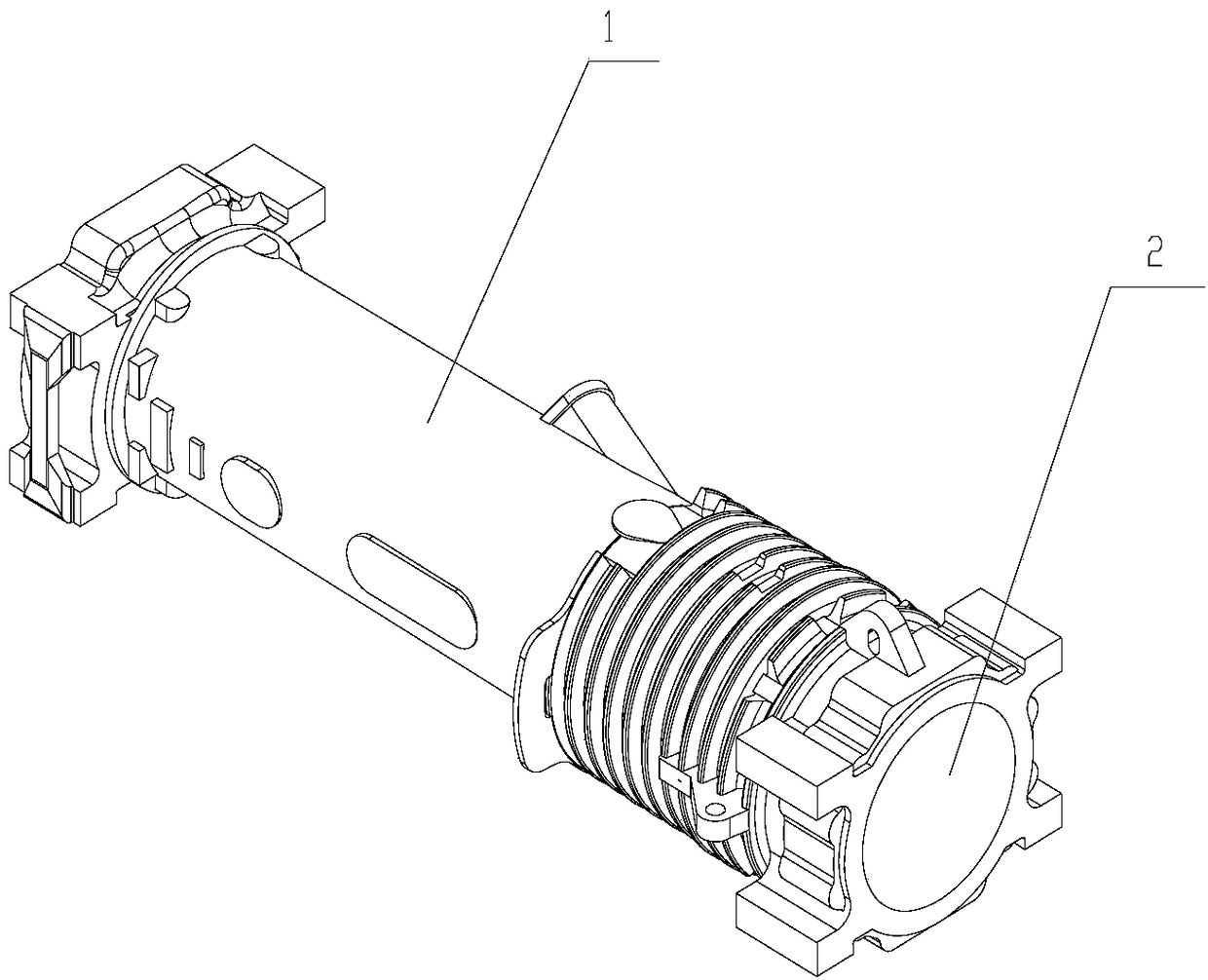

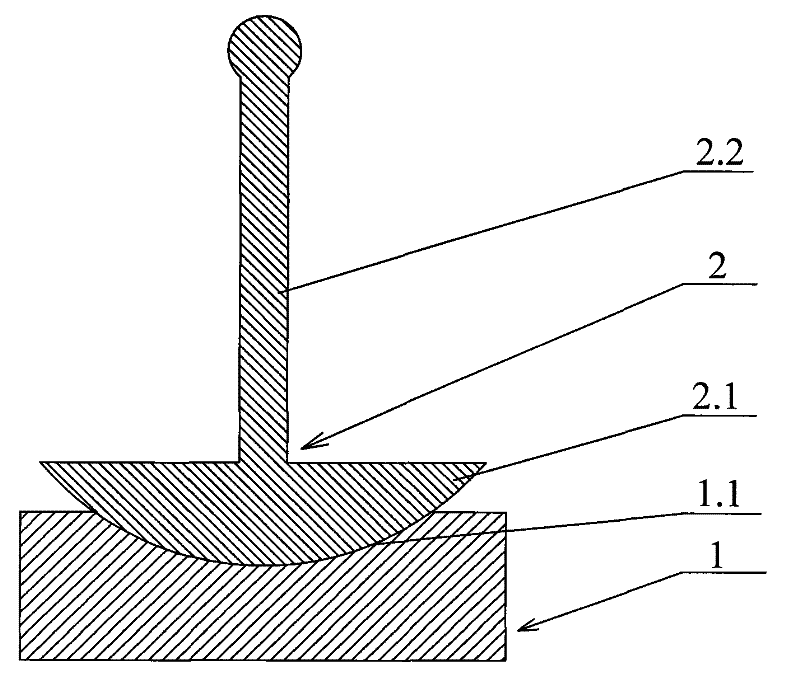

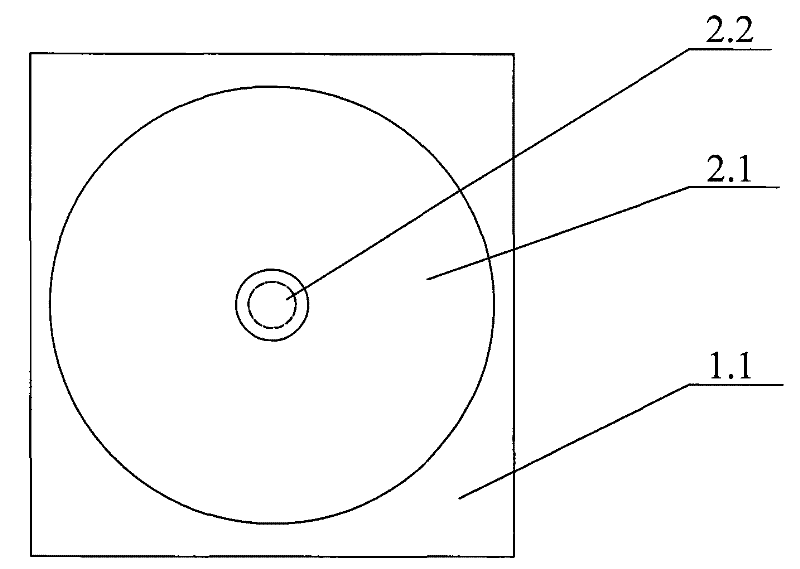

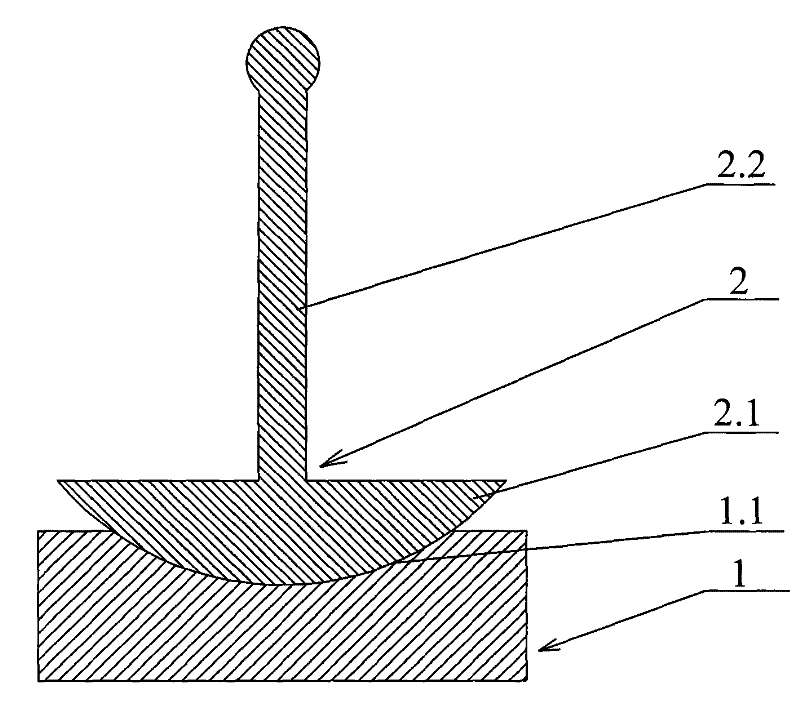

Sampling device and sampling method for accurate quantification of carbon content in spheroidal graphite cast iron

ActiveCN101776539AReduces shrinkage tendencyHigh precisionWithdrawing sample devicesDuctile ironMaterials science

The invention discloses a sampling device for accurate quantification of carbon content in spheroidal graphite cast iron and additionally discloses a sampling method using the sampling device for the accurate quantification of the carbon content in the spheroidal graphite cast iron. According to the technical scheme of the invention, the sampling device for the accurate quantification of the carbon content in the spheroidal graphite cast iron comprises a sampling base and a sampling handle. A sampling cavity is arranged on the sampling base. The wall surface of the sampling cavity is a spherical crown surface. The sampling handle comprises an operating handle and a sampling ball. The sampling ball is connected with the bottom end part of the operating handle. The diameter of the sampling ball is the same as the diameter of the sampling cavity. By using the device, the precision of carbon content detection is improved, the operation is convenient and the shrinkage trend of castings is reduced.

Owner:JIANGSU FAW FOUNDRY

Smelting method for cylinder cover of marine diesel engine

The invention relates to the technical field of marine diesel engines, and particularly relates to a smelting method for the cylinder cover of a marine diesel engine. The smelting method comprises the following steps of: proportioning, smelting original molten iron, performing spheroidization treatment, performing primary inoculation treatment, performing secondary inoculation treatment, and pouring. During smelting, a certain amount (about 0.25%) of Mn is added, so as to ensure that the content of pearlites meets technical requirements while ensuring the strength of castings; 1.3-1.8% of T-1 type spheroidizing agent is used for performing inoculation twice, and stream inoculation is performed during the secondary inoculation, so that the spheroidization rate can be increased, the spheroidization degeneration of the castings can be prevented, and the inoculation effect can be ensured; and moreover, the T-1 type spheroidizing agent is a heavy-rare-earth ferrite type spheroidizing agent capable of effectively stabilizing ferrite, ensuring the low content of rare earth, and greatly reducing the shrinkage trend of the castings.

Owner:CRRC QISHUYAN CO LTD

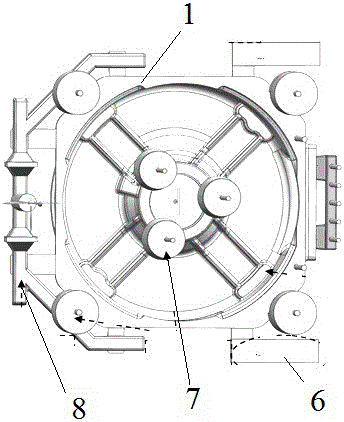

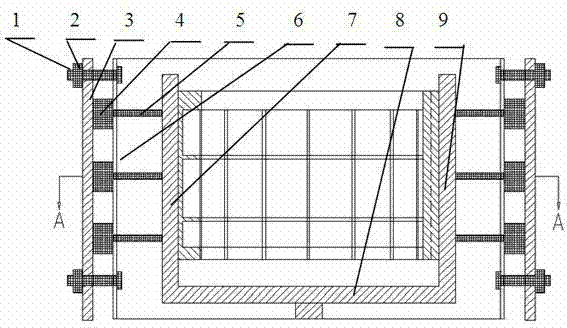

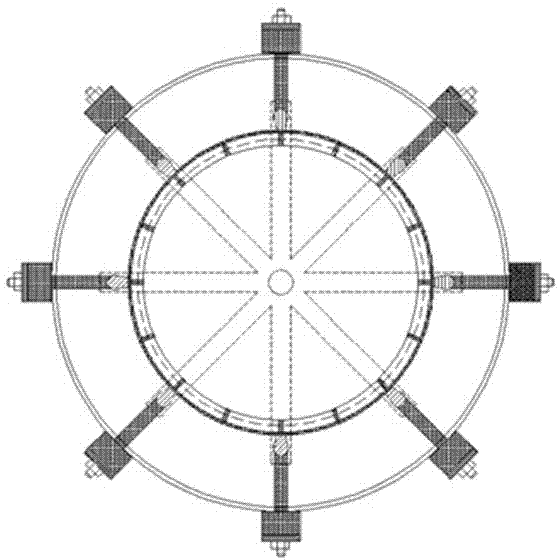

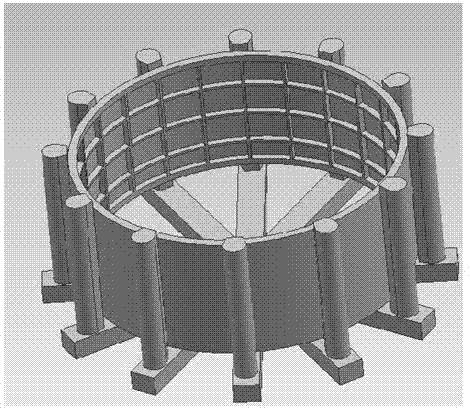

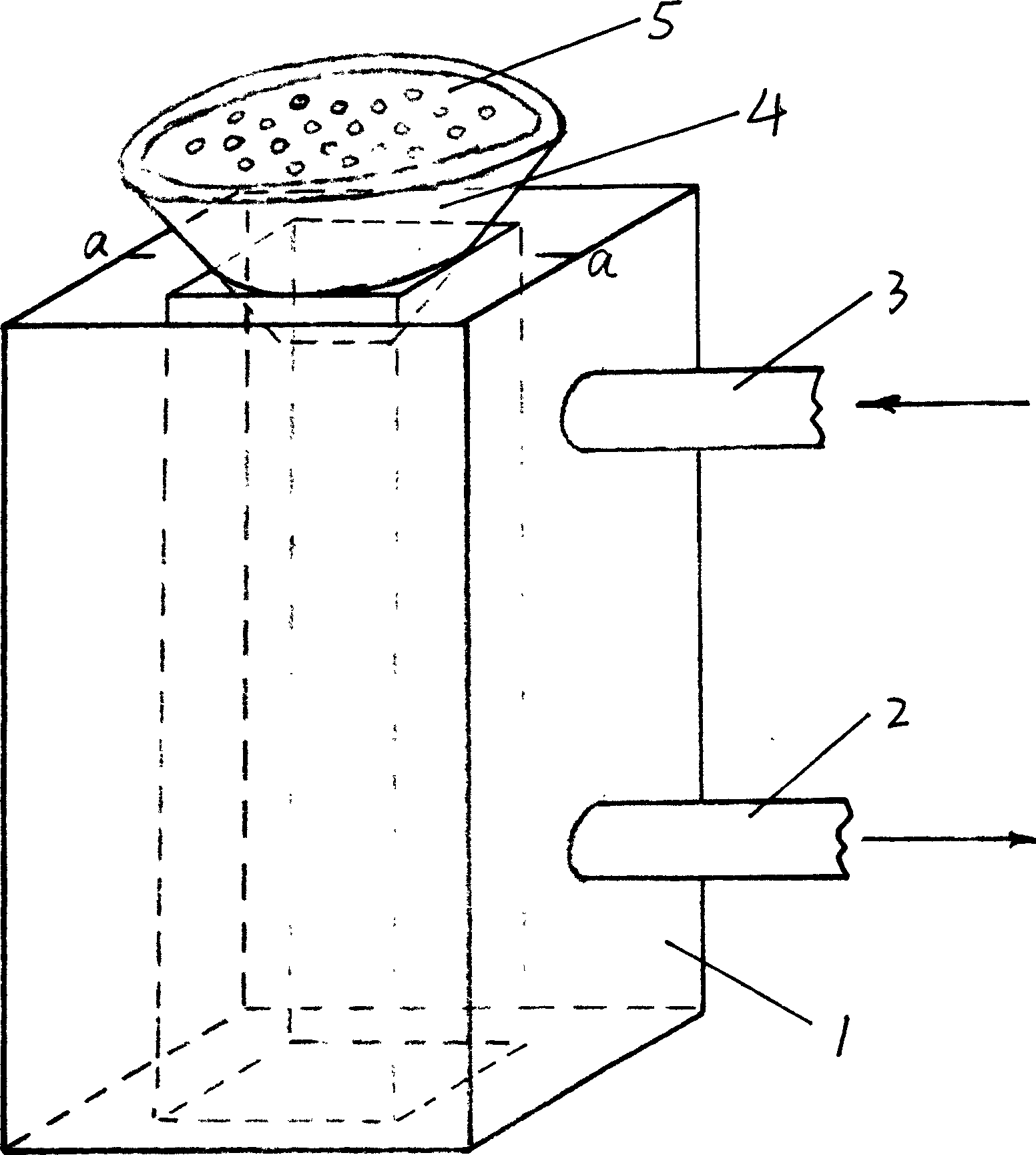

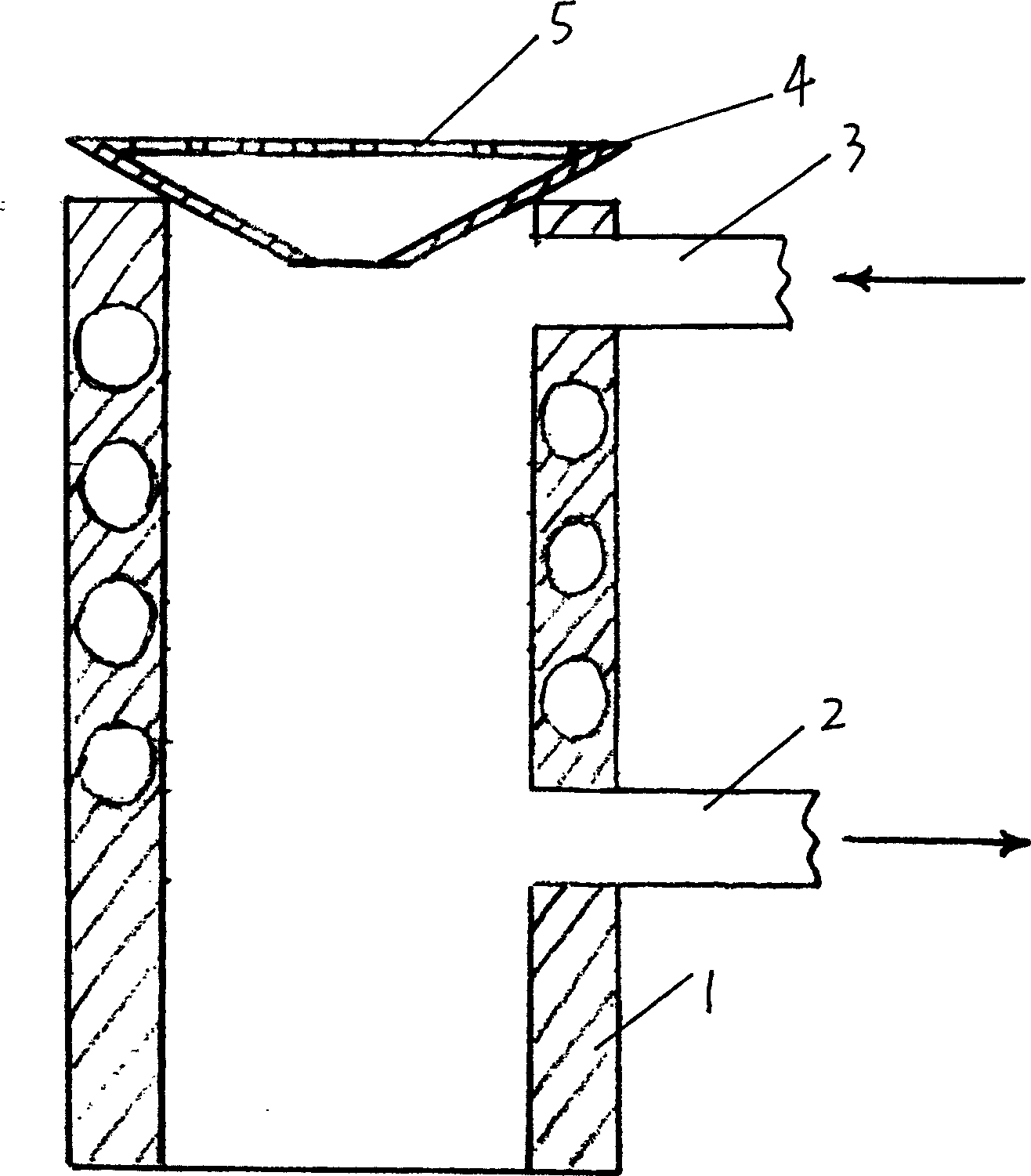

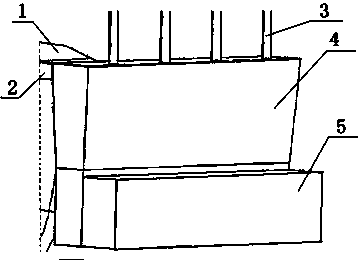

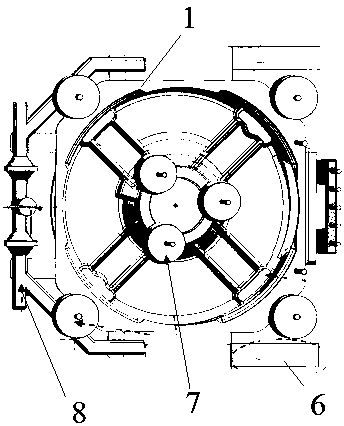

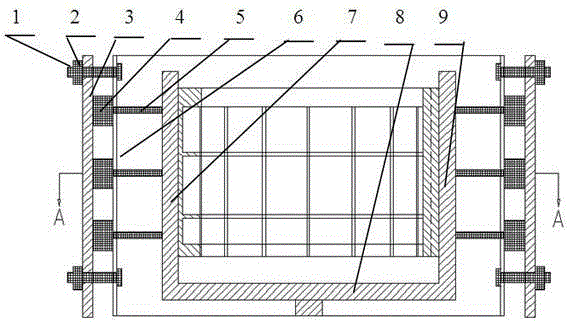

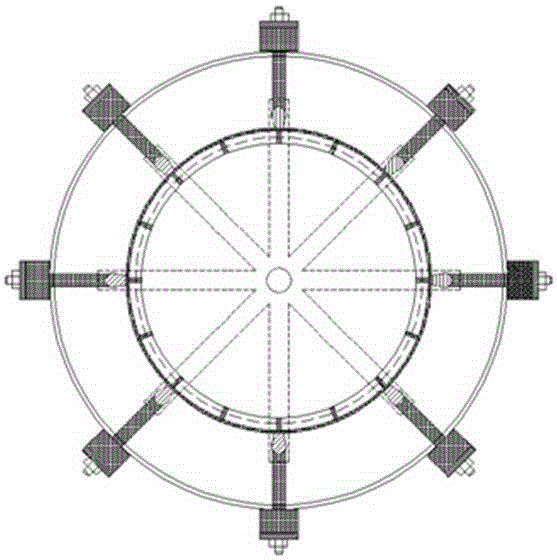

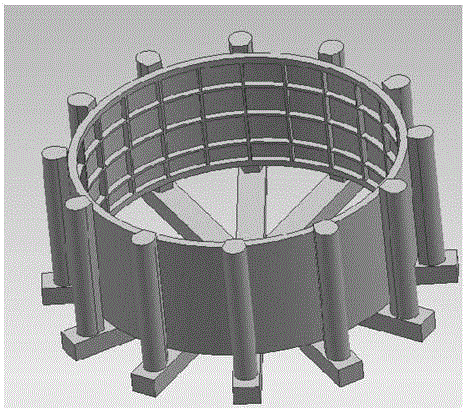

Large cylindrical shell aluminum alloy casting low-pressure casting and shrinking control device

The invention discloses a large cylindrical shell aluminum alloy casting low-pressure casting and shrinking control device. The large cylindrical shell aluminum alloy casting low-pressure casting and shrinking control device comprises a sand box, a casting, a pouring system, vibrators and vibration guide rods. The vibration guide rods are connected between a vertical cylinder pouring channel of the pouring system and the sand box. The vibrators are arranged on the outer surface of the sand box. The vibration direction of the vibrators is in line with the direction of the guide rods and tightly connected with the guide rods. The vibrators are adopted for providing a vibration source, the vibration guide rods are used for vibrating and guiding the casting and vibration is generated in the casting. Vibration transmitted by the guide rods is used for eliminating shrinking formed in the casting in the solidifying process. The vibrators vibrate in the normal direction of the outer surface of the cylindrical sand box and the guide rods are arranged in the normal direction of the outer surface of the sand box and coincide with the vibration direction of the vibrators. Meanwhile, the direction of the guide rods is parallel to the normal direction of the outer surface of the casting. According to the large cylindrical shell aluminum alloy casting low-pressure and shrinking control device, the density of the casting is reduced, the tendency to shrinking of the casting is relieved and the qualification rate of the casting is greatly improved.

Owner:HARBIN INST OF TECH

Novel austenite ductile cast iron production and improvement technique

InactiveCN104264034AImproved fluidity and filling capacity of molten ironReduced shrinkage tendency of castingsSilicon ironCast iron

The invention discloses a novel austenite ductile cast iron production and improvement technique. The austenite ductile cast iron comprises the following components in parts by mass: 2.5-2.6% of C, 4.6-4.8% of Si, 0.55-0.65% of Mn, 19-20% of Ni and 1.55-1.65% of Cr. In the smelting production process, the austenite ductile cast iron is prepared from the following components in parts by mass: 58% of returns, 30.95% of pig iron, 7.7% of nickel plate, 2% of 75A silicon iron, 0.25% of electrolytic manganese and 1.1% of chromium iron. The technique has the characteristics of low cost and wide application range, and the normal-temperature static properties and high-temperature dynamic properties can respectively reach or exceed the requirements for high-nickel ductile cast iron. The austenite ductile cast iron has the advantages of reasonable proportioning, stable performance, higher flowability and cavity filling capacity of molten iron, lower shrinkage porosity tendency of the casting, and obviously higher normal-temperature static properties, achieves the goal of dual optimization of cost and performance, can ensure the quick performance of production, and enhances the production efficiency.

Owner:西峡飞龙特种铸造有限公司

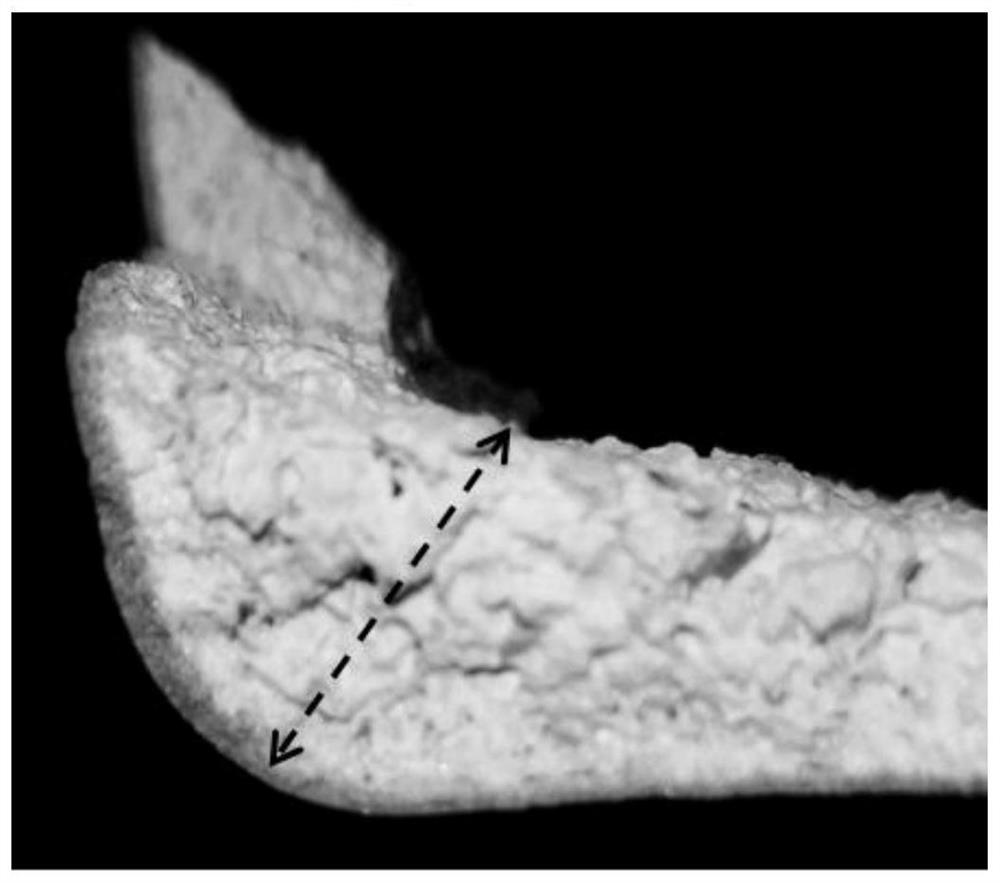

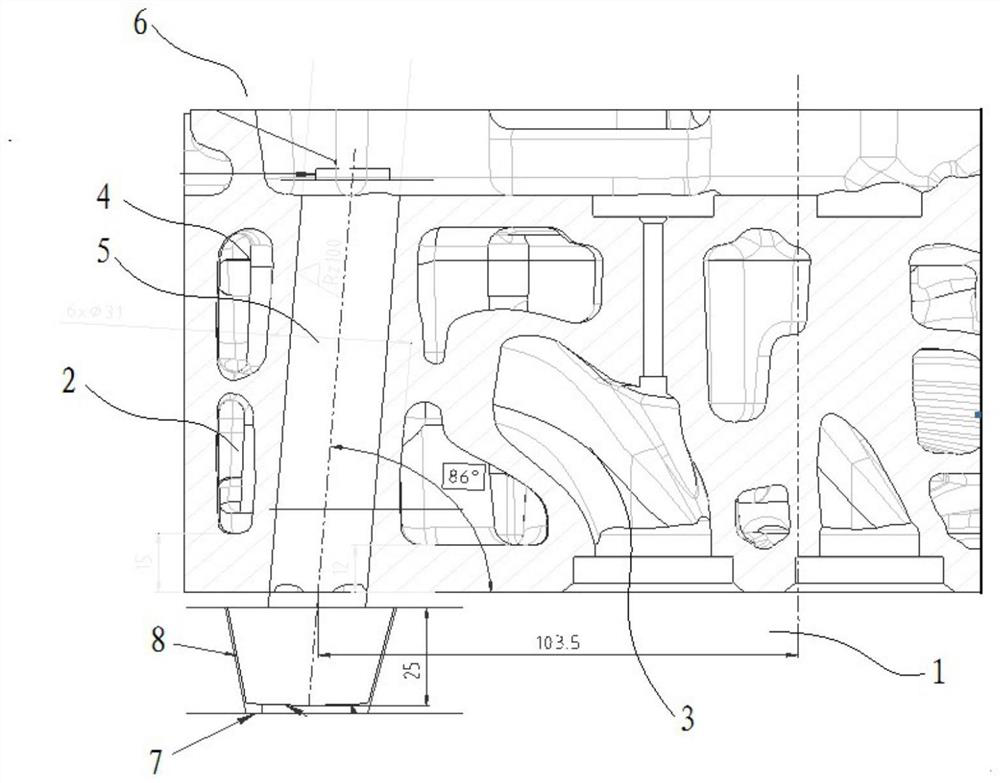

Internal chill process for improving shrinkage porosity of vermicular iron cylinder head

InactiveCN111468695AEffective improvementReduce volumeFoundry mouldsFoundry coresCylinder headCarbon steel

The invention discloses an internal chill process for improving shrinkage porosity of a vermicular iron cylinder head. The internal chill process comprises the following steps that the internal chillis used for chilling from the inside of a casting hot spot when the vermicular iron cylinder head is produced, wherein the internal chill needs to be placed in a cavity and kept fixed during casting,and the internal chill and molten iron can be fused into a whole during pouring; the internal chill is fused with the casting and is removed during machining; the internal chill is placed in a bolt hole part and inserted into a sand core base to be fixed; the internal chill is placed in a fuel injector hole, is wrapped in a sand core during sand shooting, and is fused with the molten iron into a whole during pouring; and the internal chill is made of low-carbon steel. According to the internal chill process, the internal chill made of the low-carbon steel is fixed to the center of the hot spotpart in a certain modes, chilling is directly conducted from the center part where shrinkage porosity is likely to occur, the action effect is high, and the chilling effect is good; compared with chillers currently used in the industry, the internal chill is smaller in size, lighter in weight and more convenient to use in the production process and transport in a logistics mode.

Owner:CHINA FIRST AUTOMOBILE +1

Low-zinc hot-dip-coating aluminum alloy coating material achieving alteration by chrome coordination compound

InactiveCN103131996AInhibition of chemical reactionsQuality improvementHot-dipping/immersion processesDip-coatingAlloy coating

The invention discloses low-zinc hot-dip-coating aluminum alloy coating material achieving alteration by chrome coordination compound. The low-zinc hot-dip-coating aluminum alloy coating material achieving the alteration by chrome coordination compound comprises, by weight, 3.25% of chrome coordination compound Cr (CO) 6, 30% of Zn, 1.0% of Si, 0.7% of tombarthite additives, and balanced Al and unavoidable trace impurities. The low-zinc hot-dip-coating aluminum alloy coating material achieving the alteration by chrome coordination compound solves the problems that steel plate needle-shaped coating leakage can occur to zinc-aluminum coating material and a coating layer can not effectively protect cathodes of a scratch and a notch and also achieves the performances, such as forming machining, welding and coating, of the zinc-aluminum coating material.

Owner:贵州铝厂有限责任公司

Method for producing high puriy, laminar cast ingot of Nd-Fe-B alloys

A process method for a thin plate NdFeB ingot characterizes in purifying the NaFeB melt and controlling the cooling speed of the ingot after casting, in which, the purification is to add Ca and its alloy and let the melt pass through a pouring cup with a mini-hole foam ceramic filter plate to enter into the mold and the control of the cooling speed is realized by using a flat mold made of Cu and its alloy attached by two water cooling cover dies at its both sides to greatly reduce impurities in the ingot and refine the grains so as to improve the structure and increase the rate of finished products.

Owner:SICHUAN UNIV

Preparation method and application of inoculant for thin-wall quenched part

The invention discloses a preparation method of an inoculant for a thin-wall quenched part. The preparation method comprises the following steps: 70%-80% of Si, 0.6%-1% of Sr, 0-3% of Ba, 0.9%-1.4% of Al, 0-0.7% of Ca and the balance of Fe and inevitable trace elements are mixed, melted, stirred, cooled and ground, then a product is mixed with Fe3O3 powder, and the mixture is pressed into clusters and ground. The invention further discloses an application of the inoculant for the thin-wall quenched part. With application of the inoculant for the thin-wall quenched part, the combination property of the thin-wall quenched part can be improved, and the inoculation efficiency can be improved.

Owner:成都宏源铸造材料有限公司

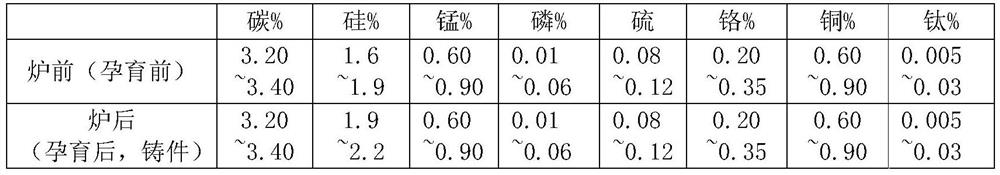

Electric furnace smelting high-strength medium heat-resistant alloy cast iron and smelting method thereof

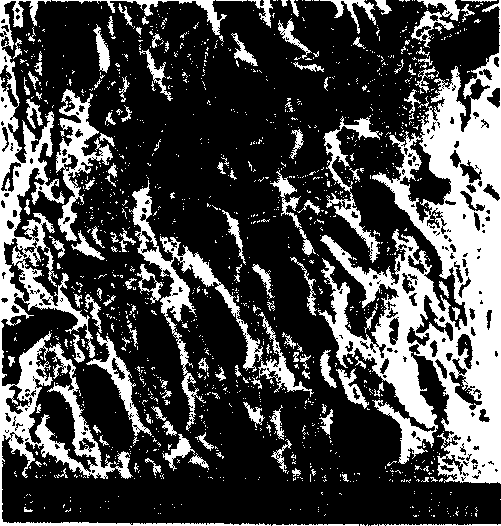

The invention discloses high-strength medium-heat-resistance alloy cast iron smelted through an electric furnace and a smelting method of the high-strength medium-heat-resistance alloy cast iron in the technical field of cast iron production. The alloy cast iron is prepared from, by mass, 3.2%-3.4% of carbon, 1.9%-2.2% of silicon, 0.01%-0.06% of phosphorus, 0.06%-0.12% of sulfur, 0.6%-0.9% of manganese, 0.2%-0.35% of chromium, 0.6%-0.9% of copper, 0.005%-0.03% of titanium and the balance iron and inevitable impurities. Different from traditional gray cast iron raw materials, pig iron is not added in the scheme of the invention, but a proportioning process of scrap steel, foundry returns and a carburant is used, and meanwhile, a precious molybdenum alloy is replaced by adopting alloy matching of copper and chromium, so that the manufacturing cost is greatly reduced, in addition, a treatment mode of silicon iron pretreatment of a part of the carburant and tapping composite inoculation is adopted, and the production efficiency is greatly improved. By means of the method, more than 90% of A-type graphite is obtained in a metallographic phase of a casting body, the lanthanum-containing inoculant can promote isometric crystal growth and inhibit dendritic crystal growth in the cast iron solidification process, a feeding channel in molten iron is effectively prolonged, the shrinkage porosity tendency of the casting is reduced, and it is guaranteed that leakage does not exist in an installation pressure test.

Owner:宜宾普什联动科技有限公司

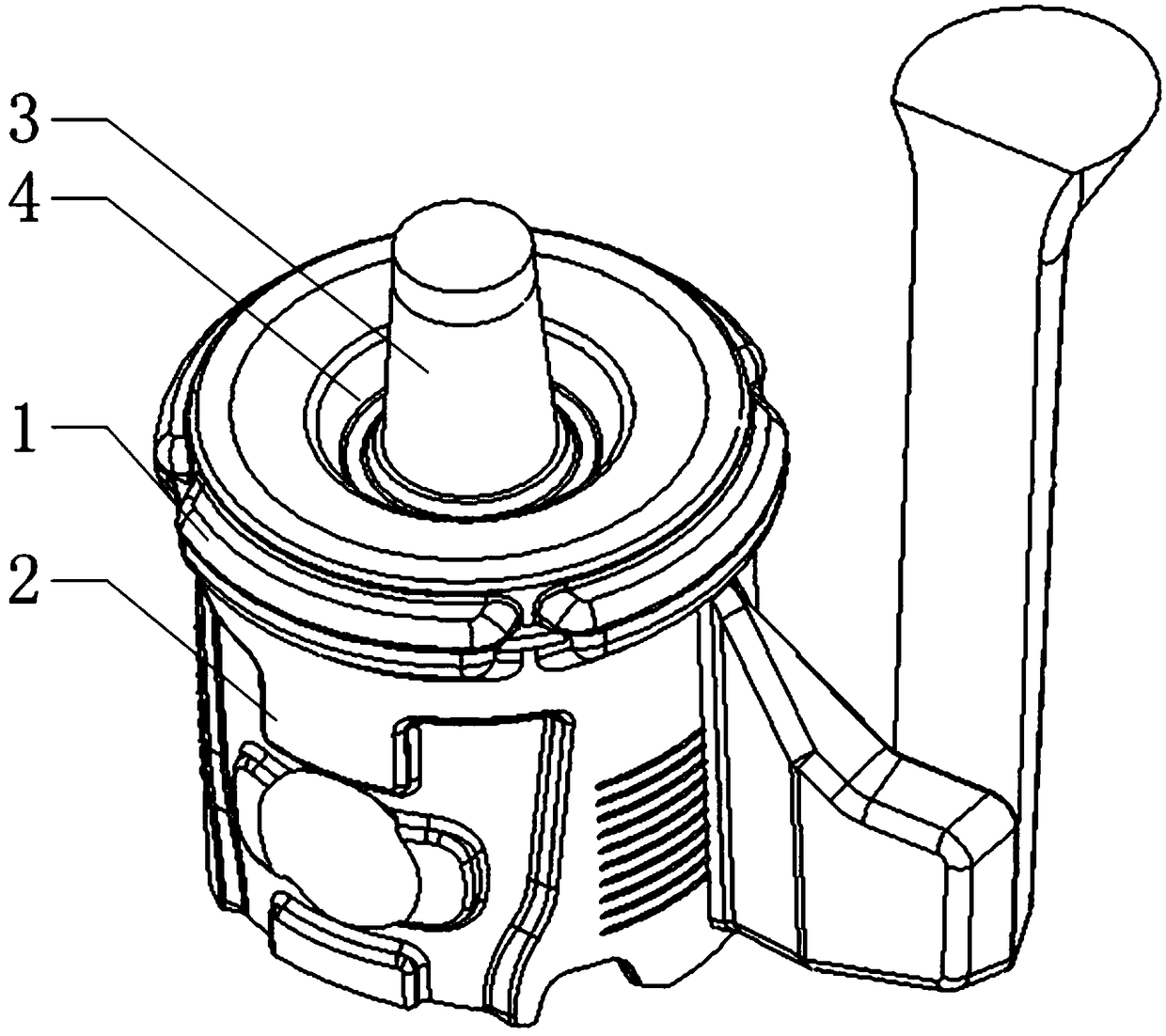

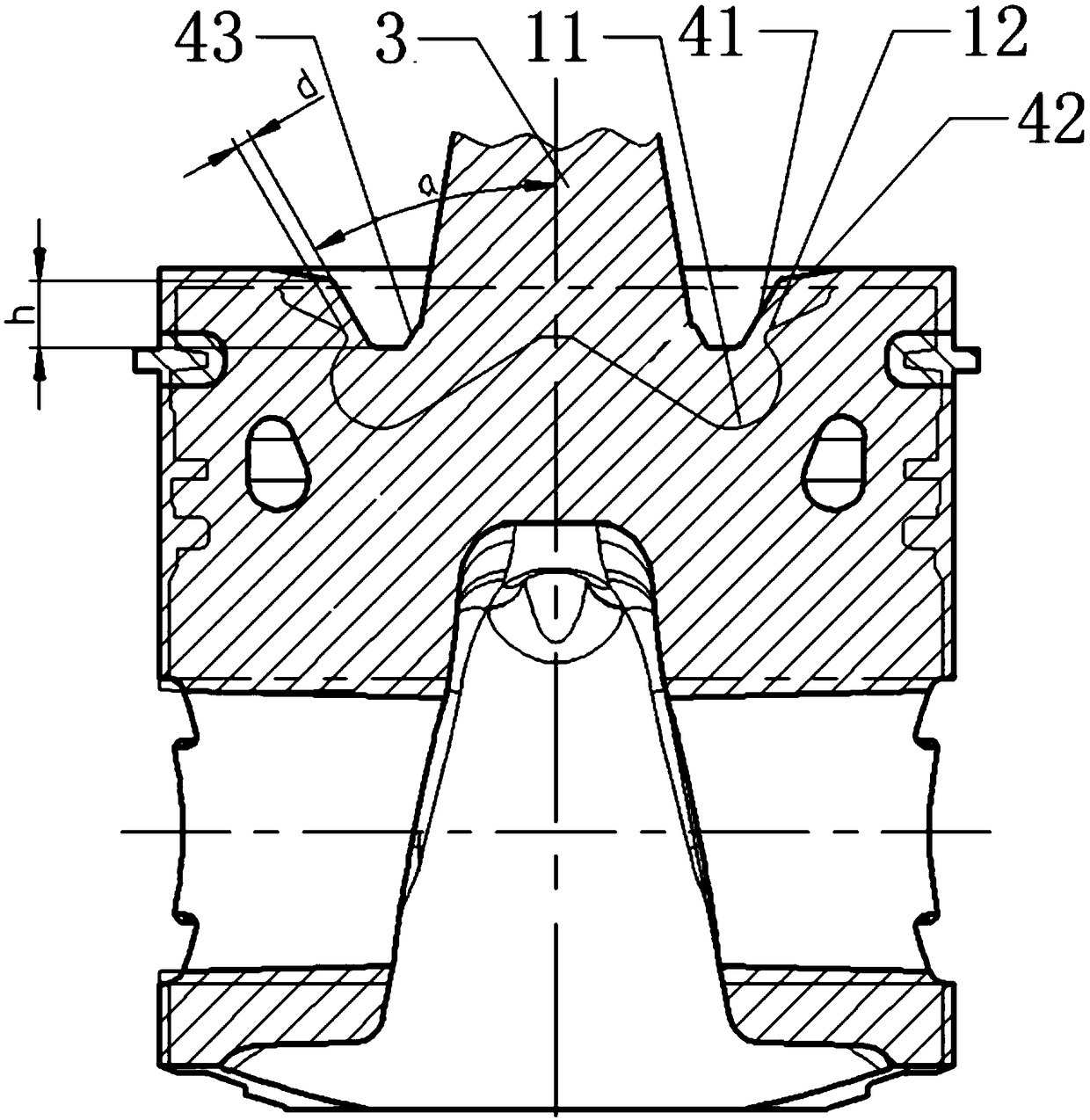

Engine piston blank and machining method thereof

InactiveCN109209673AReduced risk of crack failureIncrease profitMachines/enginesPistonsCombustion chamberFailure risk

The invention discloses an engine piston blank which comprises a skirt portion and a head portion. A dead head is arranged on the top surface of the head portion. The top surface of the head portion is provided with an annular groove which surrounds the dead head and is recessed downwards. The bottom surface of the annular groove is close to the bottom surface of the combustion chamber of a pistonfinished product. The inner side wall of the annular groove is the outer peripheral side face of the dead head. The outer side wall of the annular groove serves as a machining positioning surface andis positioned close to the throat of the piston finished product. Machining allowance layers are arranged between the machining positioning surface and the throat, and also between the bottom surfaceof the annular groove and the bottom surface of the combustion chamber. The general shape of the combustion chamber and the throat is directly cast, and the metallographic structure of a local area is refined. The method is easy to realize and the effect is better. Meanwhile, the cost is lower, and the fatigue strength is improved. The purpose of greatly reducing the cracking failure risk of thethroat is achieved. A formed blank surface is used as a machining positioning surface for subsequent machining, and then the follow-up mechanical machining is carried out. The piston quality is improved. The invention further discloses a machining method of the engine piston blank.

Owner:湖南江滨机器(集团)有限责任公司

Nickel-free low-silver-content Tibetan silver alloy with excellent die-casting performance and process thereof

The invention discloses a nickel-free low-silver-content Tibetan silver alloy with excellent die-casting performance and a process thereof. The alloy is prepared from the following components of, in percentage by weight, 0.4w%-0.5w% of B, 1.0w%-1.2w% of Ca, 2.0w%-3.5w% of Al, 1.0w%-1.8w% of Si, 0.2w%-0.3w% of Os, 1.0w%-1.4w% of Ge, 6.0w%-9.0w% of Fe, 29.0w%-31.0w% of Ag and the balance copper. Thenickel-free low-silver-content Tibetan silver alloy is a novel nickel-free Tibetan silver alloy which does not exist in the market, and has excellent die-casting performance; and through industrialization of the alloy, the problem of the current Tibetan silver alloy can be solved, and the variety of the low-silver-content alloy for jewelry in the market can be greatly enriched.

Owner:GUANGZHOU YUZHI TECH CO LTD

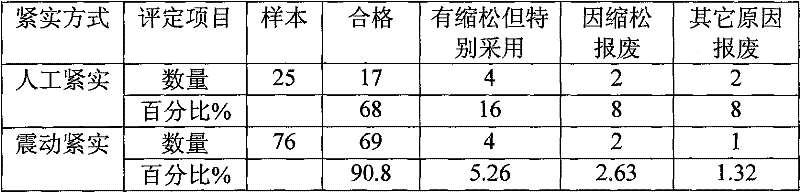

Furan resin sand mold for producing heavy castings and sand core bumping method

ActiveCN101773987BImprove firmnessQuality improvementFoundry mouldsMoulding machinesFuranSurface level

The invention relates to a furan resin sand mold for producing heavy castings and a sand core bumping method. According to the technical scheme of the invention, the bumping method comprises the following steps of: a, correcting a table-surface level of a bumper first when the bumper is arranged and then checking up accelerations at four corners of the table-surface by using a seismometer and keeping the numerical values of the accelerations of the four angles to between 20 and 30 m / s<2>; b, adding a furan resin and a furan self-hardening sulfuric curing agent into molding sand and stirring the mixture to obtain sand mud for making mold and core sands, wherein the added weight of the furan resin is 0.95 to 1.15 percent based on the added weight of the molding sand and the added weight of the furan self-hardening sulfuric curing agent is 35 to 45 percent based on the added weight of the furan resin and the sulfuric acid in the furan self-hardening sulfuric curing agent is 9 to 35 percent by weight; and c, pouring the sand mud into a box till the level of the sand mud is 100 to 150 millimeters higher than the box surface and then starting the bumper to perform bumping for 10 to 50 seconds. The method has the advantages of greatly improving the percent of pass, greatly improving the loosening conditions of the casting and greatly reducing the rejection rate.

Owner:JIANGSU FAW FOUNDRY

A kind of preparation method of low-temperature ferritic nodular cast iron attached casting test block

ActiveCN106424572BDense tissueNo shrinkagePreparing sample for investigationFoundry mouldsCasting moldDuctile iron

The invention relates to a casting process, in particular to a low-temperature ferrite ductile cast iron auxiliary casting test block preparation method. In order to solve the problem of totally consistent performances of an auxiliary casting test block and a casting, the invention proposes the low-temperature ferrite ductile cast iron auxiliary casting test block preparation method. The low-temperature ferrite ductile cast iron auxiliary casting test block preparation method uses a pouring system, a casting mold and an auxiliary casting test block mold; the uppermost end of the auxiliary casting test block mold is connected with the casting through a test block sprue connecting way; an overflow way is formed above the auxiliary casting test block mold; cold iron is put in the auxiliary casting test block performance taking place on the lower side of the auxiliary casting test block mold; and the auxiliary casting test block mold is vertically placed. Through transformation, a prepared auxiliary casting test block and a single casting Y-shaped test block have similar performances to reflect real casting performances.

Owner:ASIMCO INT CASTING CO LTD SHANXI

Method for preparing shell for investment casting and shell

PendingCN113953463AReduces shrinkage tendencyUniform grainMoulding machinesInvestment castingSlurry coating

The invention provides a method for preparing a shell for investment casting. The method comprises more than two shell layer preparation steps, at least part of the shell layer preparation steps comprises the steps of slurry coating, sand spraying and drying which are carried out in sequence, at least one shell layer preparation step further comprises a local isolation step, and in the local isolation step, an isolating membrane is arranged at the position, needing thickness control, of the shell. The invention also provides the shell prepared by using the method. The ceramic shell prepared through the method is high in thickness uniformity, and shrinkage porosity and grain control of the local area of a precision casting are facilitated. The invention further relates to a gas turbine blade shell prepared by using the preparation method.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Vaginal dilation blade for vaginal speculum for obstetrics and gynecology department

InactiveCN107951461AImprove liquidityReduces shrinkage tendencySurgeryMetallic material coating processesVaginal dilationSurface layer

The invention relates to a vaginal dilation blade for a vaginal speculum for the obstetrics and gynecology department. The vaginal dilation blade comprises an upper vaginal dilation blade body and a lower vaginal dilation blade body which are coordinated with each other, wherein the vaginal dilation blade bodies are made of copper alloy, and the surfaces, contacting with the vagina, of the vaginaldilation blade bodies are provided with treated surface layers. The vaginal dilation blade has the advantages that the nickel-alloy coating layers of the vaginal dilation blade are subjected to passivation and a pore sealing process, so that the surfaces of the nickel-alloy coating layers are smooth and easy to clean, the corrosion resistance of the nickel-alloy coating layers are increased effectively, the nickel-alloy coating layers are harmless when contacting with the epidermal tissue of a human body, and a certain antibacterial effect is achieved.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

High vermicularization rate vermicular graphite cast iron single-cylinder diesel engine body and preparation method thereof

ActiveCN104480377BNarrow crystallization rangeImprove liquidityCompacted graphite ironChemical composition

The invention relates to a single cylinder diesel engine body and particularly relates to a vermicular graphite cast iron single cylinder diesel engine body with high vermicular graphite rate. The single cylinder diesel engine body comprises the following chemical components in percentage by mass: 3.5-3.8% of C, 2.1-2.6% of Si, 0.5-0.8% of Mn, less than 0.08% of P, less than 0.03% of S and the balance of iron and inevitable impurities. The single cylinder diesel engine body provided by the invention has the characteristics of less inclination of shrinkage cavity and shrinkage porosity and long service life. The invention further provides a preparation method of the single cylinder diesel engine body, which is reasonable in process.

Owner:SHANDONG YUANTONG MASCH CO LTD

Shrinkage Porosity Control Device for Low Pressure Casting of Aluminum Alloy Castings with Large Cylindrical Shell

Owner:HARBIN INST OF TECH

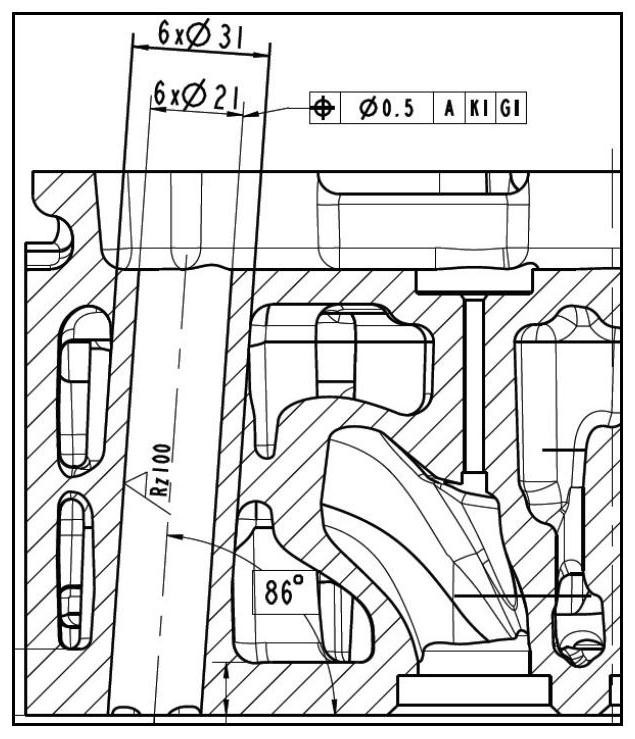

Sand core structure for cylinder cover casting tappet hole precasting and precasting method

PendingCN114749604ALow shrinkageReduces shrinkage tendencyFoundry mouldsFoundry coresClassical mechanicsStructural engineering

The invention provides a sand core structure for cylinder cover casting tappet hole precasting and a precasting method. The sand core structure comprises a tappet hole sand core used for forming a casting tappet hole and a supporting sand core used for supporting the tappet hole sand core. The supporting sand cores are distributed and connected to the base core at intervals, the supporting sand cores are arranged on the base core in an embedded mode, and the upper surfaces of the supporting sand cores and the base core are located on the same horizontal plane; at least two tappet hole sand cores are obliquely arranged on the supporting sand core, and a set included angle is formed between the inclination angle of the at least two tappet hole sand cores and the ground plane. The tappet hole sand core is additionally arranged, the tappet hole structure is achieved in a pre-casting mode, and the problem of high cost caused by machining is solved; in addition, the invention further provides a precasting method, the tappet hole position machining allowance is omitted, and molten iron consumption is reduced.

Owner:CHINA FIRST AUTOMOBILE +1

Novel material of sliding valve pair for railway vehicle brake valve

ActiveCN103234056BReduce coefficient of frictionImprove wear resistanceSlide valveSpool valveControl theory

The invention discloses a novel sliding valve pair for a railway vehicle brake valve. The novel sliding valve pair comprises a sliding valve and a sliding valve sleeve which are both made of brand-new materials, so that abrasion resistance of the sliding valve pair is enhanced. The sliding valve is soft, the sliding valve sleeve is hard, the sliding valve sleeve is long in service life, and the sliding valve is easy and convenient to repair and maintain.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Method for producing high puriy, laminar cast ingot of Nd-Fe-B alloys

A process method for a thin plate NdFeB ingot characterizes in purifying the NaFeB melt and controlling the cooling speed of the ingot after casting, in which, the purification is to add Ca and its alloy and let the melt pass through a pouring cup with a mini-hole foam ceramic filter plate to enter into the mold and the control of the cooling speed is realized by using a flat mold made of Cu and its alloy attached by two water cooling cover dies at its both sides to greatly reduce impurities in the ingot and refine the grains so as to improve the structure and increase the rate of finished products.

Owner:SICHUAN UNIV

Nodular cast iron with high wear resistance and long service life and preparation method of lower cylinder using the cast iron

ActiveCN106834901BCooperate wellPromote formationFoundry mouldsFurnace typesHigh wear resistanceDuctile iron

The invention discloses high-wear-resistance long-life ductile iron, comprising, by weight, 3.80-3.88% of C, 2.20-2.30% of Si, 0.55-0.65% of Mn, < / =0.020% of P, < / =0.010% of S, 0.45-0.55% of Cu, 0.30-0.40% of Mo, 0.0040-0.0060% of La, 0.035-0.045% of Mg, and the balance of iron and unavoidable impurity. The invention is intended to provide the high-wear-resistance long-life ductile iron that has high rigidity and fatigue strength and has improved tensile strength and plasticity, and a method of producing a lower cylinder with the ductile iron.

Owner:GUANGDONG ZHONGTIAN CHUANGZHAN DUCTILE IRON CO LTD

Sampling device and sampling method for accurate quantification of carbon content in spheroidal graphite cast iron

ActiveCN101776539BReduces shrinkage tendencyHigh precisionWithdrawing sample devicesDuctile ironMaterials science

Owner:JIANGSU FAW FOUNDRY

An obstetrics and gynecology speculum-expanding blade

InactiveCN107951461BImprove liquidityReduces shrinkage tendencySurgeryMetallic material coating processesEngineeringNickel alloy

A vagina-expanding blade for an obstetrics and gynecology speculum. The vagina-expanding blade is divided into upper and lower pieces, and the upper and lower two pieces of the vagina-expanding blade cooperate. The main body of the vagina-expanding blade is made of copper alloy. The surface treatment layer, the nickel alloy coating layer of the present invention is passivated and sealed after the surface is smooth and easy to clean, the corrosion resistance is effectively improved, there is no harm in contact with human epidermis, and it has a certain antibacterial effect.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

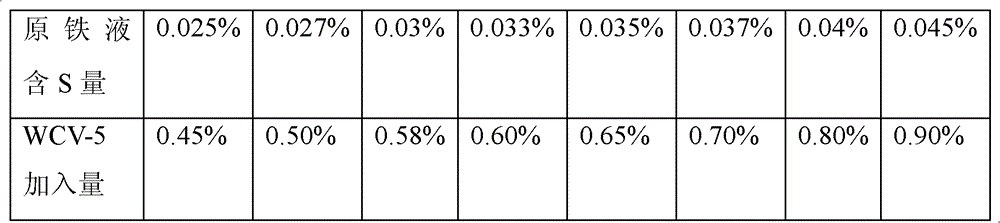

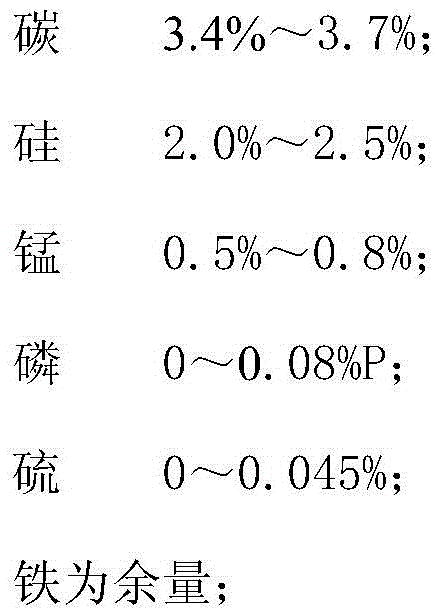

High creep rate vermicular graphite cast iron for internal combustion engine cylinder block and cylinder head and its manufacturing method

The invention relates to vermicular graphite cast iron with a high rate of vermiculation of a combustion motor cylinder body and a cylinder cover and a preparation method, and belongs to the field of casting method. The vermicular graphite cast iron with the high rate of the vermiculation of the combustion motor cylinder body and the cylinder cover and the preparation method are characterized in that the vermicular graphite cast iron with the high rate of the vermiculation comprises the following chemical components: 3.4%-3.7% of carbon, 2.0%-2.5% of silicon, 0.5%-0.8% of manganese, 0%-0.08% of phosphorus and 0%-0.04% of sulphur, with the balance being iron. In a microscopic structure, a pearlite area accounts for 50%-70%, a ferrite area accounts for 30%-50%. The mechanical properties are as follows: strength of extension sigma b is more than or equal to 320 MPa to 400 MPa, ductility delta is 1%-4%, and hardness HB is 160-230. Due to the fact that molten iron component is near an eutectic point, scope of crystallization is narrow, liquidity is good, casting performance is good, the tendency of a casting shrinkage cavity and shrinkage porosity is little, a wholesome cylinder cover cast and wholesome cylinder body cast are easy to obtain, the service lives of the cylinder cover and the cylinder body are prolonged, certainly, the vermicular graphite cast iron with the high rate of the vermiculation of the combustion motor cylinder body and the cylinder cover and the preparation method play a pivotal role of the performance of improving the combustion motor and prolonging the service life of the combustion motor.

Owner:SHANDONG YUANTONG MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com