Sampling device and sampling method for accurate quantification of carbon content in spheroidal graphite cast iron

A technology of ductile cast iron and sampling devices, which is applied in the direction of sampling devices, can solve the problems of volatility, instability, poor repeatability, etc., and achieve the effects of reducing shrinkage tendency, convenient operation, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

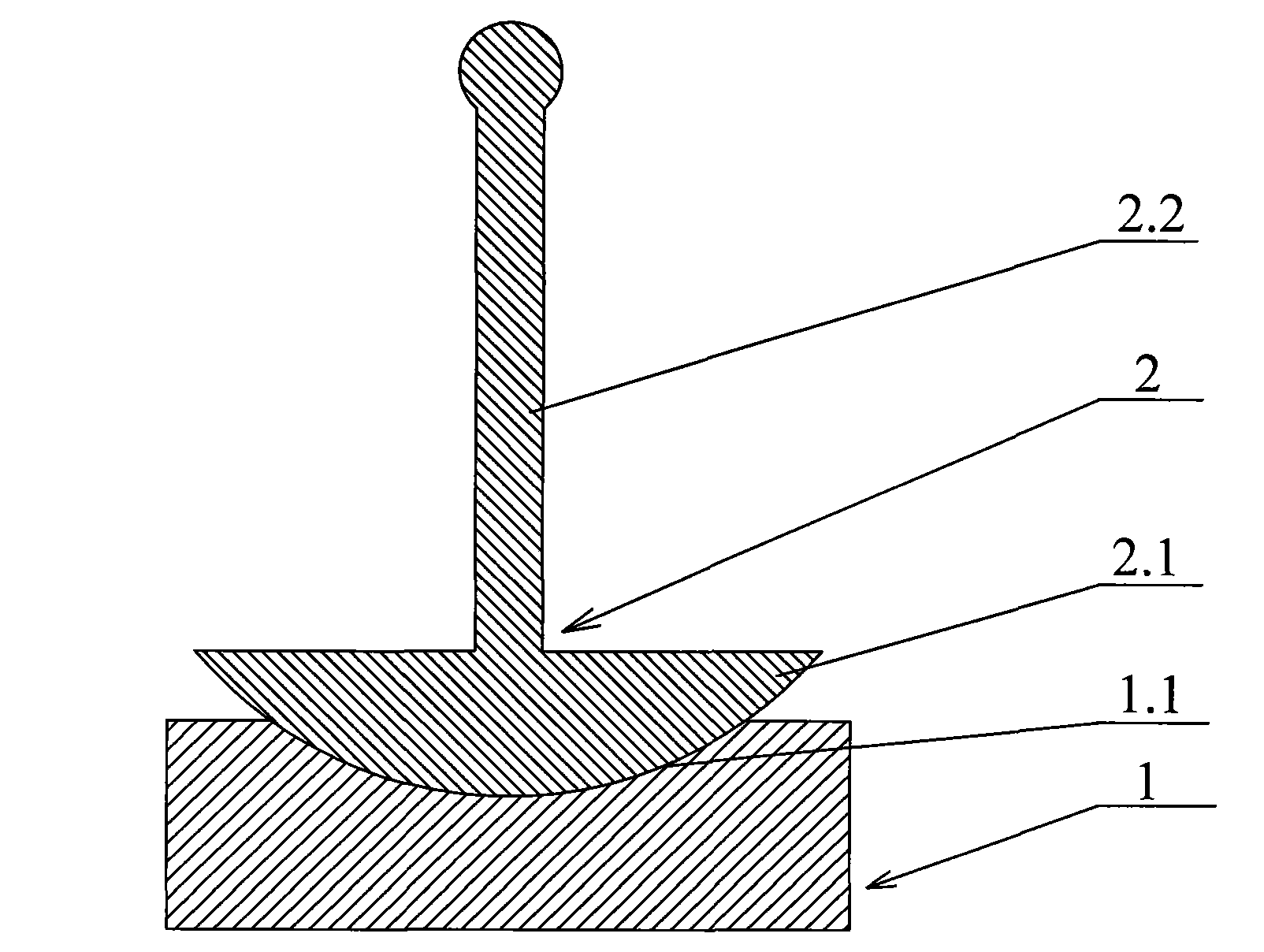

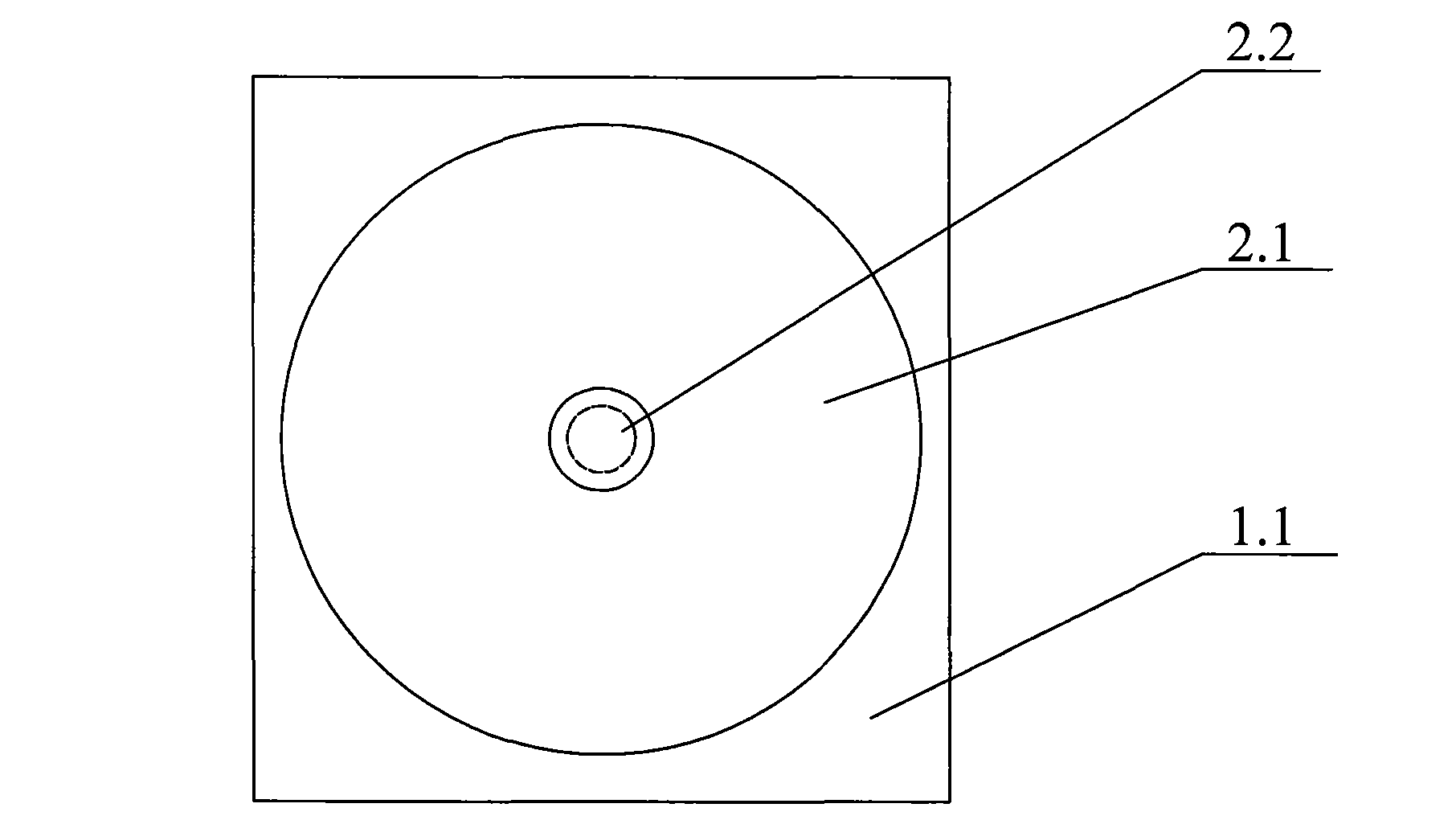

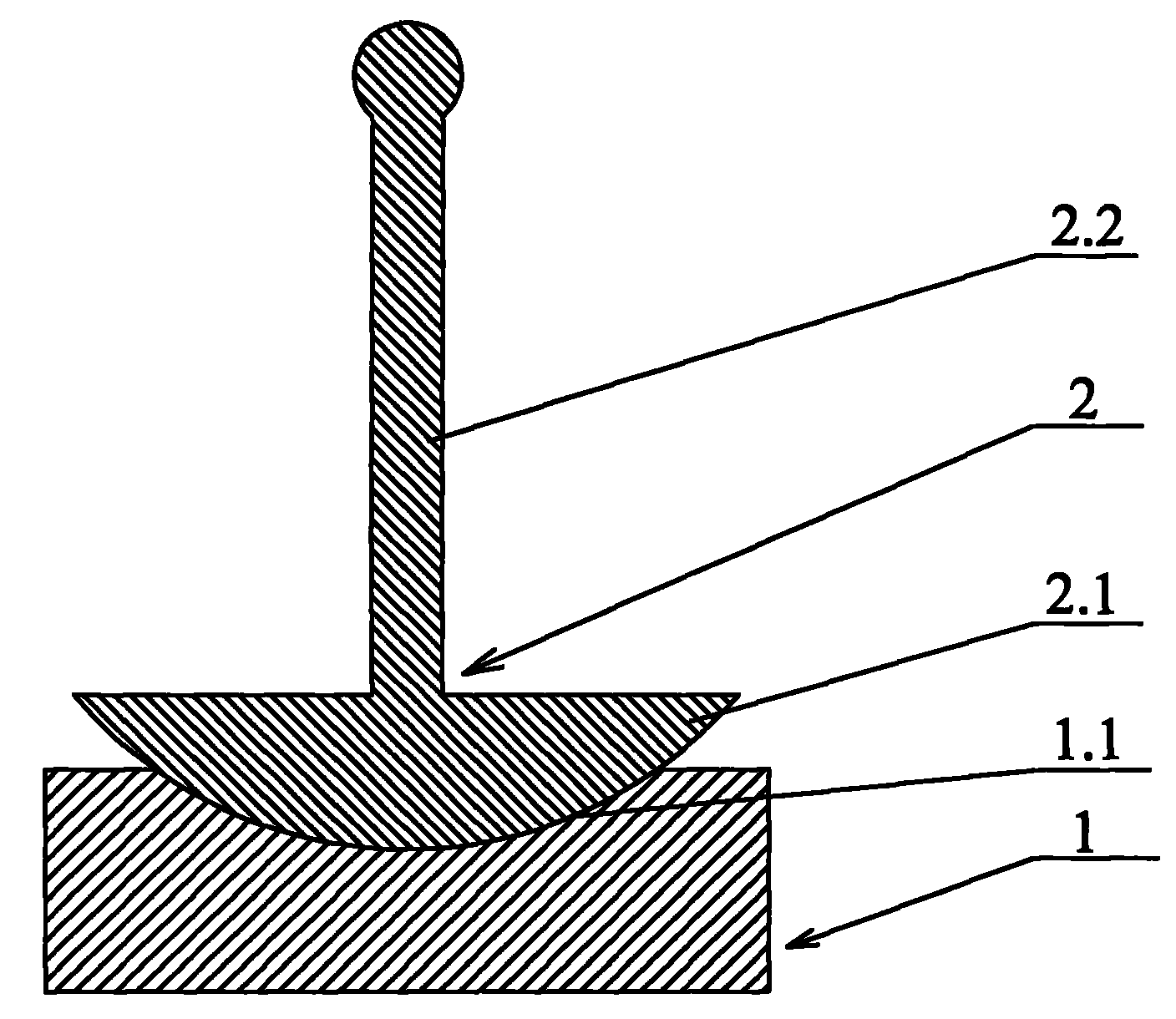

[0017] Such as figure 1 As shown: the sampling device for the precise and quantitative amount of carbon in ductile iron, which includes a sampling base 1 and a sampling handle 2. A sampling cavity 1.1 is provided on the sampling base 1, and the wall surface of the sampling cavity 1.1 is a spherical crown surface. The handle 2 includes an operating handle 2.1 and a sampling ball 2.2. The sampling ball 2.2 is connected to the bottom end of the operating handle 2.1. The diameter of the sampling ball 2.2 is the same as that of the sampling cavity 1.1.

[0018] The spherical diameter of the sampling cavity 1.1 is 280-320 mm, and the diameter of the edge of the sampling cavity 1.1 is 130-170 mm.

[0019] The sampling method using above-mentioned sampling device comprises the following steps:

[0020] a. Use a molten iron sampling spoon to take out the nodular cast ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com