High creep rate vermicular graphite cast iron for internal combustion engine cylinder block and cylinder head and its manufacturing method

A technology of vermicular graphite cast iron and vermicularization rate, which is applied in the fields of casting, high vermicularity vermicular graphite cast iron and its manufacturing method, which can solve the problems of difficulty in obtaining vermicular graphite cast iron stably and difficulty in casting production, and achieve narrow crystallization range, Improved performance and service life, less shrinkage tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

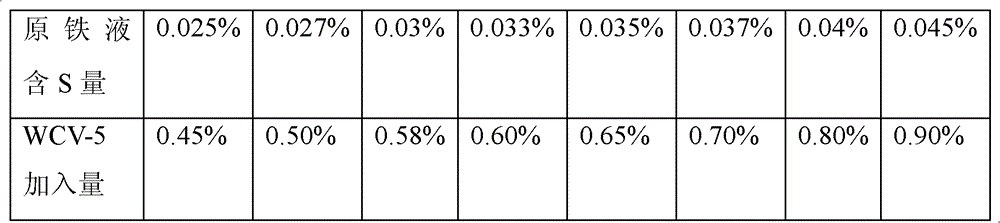

[0029] Use a medium frequency induction furnace with a capacity of 3 tons to smelt molten iron, use foundry pig iron (Z14 produced by Zhangdian Iron and Steel Plant) to produce vermicular graphite cast iron, use a direct reading spectrometer to quickly analyze the chemical composition of molten iron, and perform vermicular treatment by pouring method, casting pig iron electric furnace The S content in Zhongyuan molten iron is controlled at 0.025% to 0.045%, and the corresponding adding amount of vermicular agent is as follows:

[0030]

[0031] (data in the table are mass percentages)

[0032] In this embodiment, the sulfur content of the original molten iron is 0.027%, the added vermicular agent is 0.50% of the total material mass, and the inoculant is added in an amount of 0.6% SiFe75 and 0.2% SiCa of the total material mass.

[0033] Since there are many factors affecting vermicularization, the addition ratio of vermicularizing agent should be corrected in time according...

Embodiment 2

[0037] Use a medium frequency induction furnace with a capacity of 2 tons to smelt molten iron, use Z14 foundry pig iron produced by Jinan Gengchen Iron and Steel Factory to produce the recycled material of vermicular graphite cast iron, use direct-reading spectrometer to quickly analyze the chemical composition of molten iron, and perform vermicularization treatment by pouring method. In this embodiment, the sulfur content of the original molten iron is 0.03%, the added vermicular agent is 0.58% of the total material mass, and the inoculant is 0.6% SiFe75 and 0.2% SiCa of the total material mass.

[0038] The composition of the vermicular agent is: 11% rhenium; 4% magnesium; 1% calcium; 3% aluminum; 40% silicon;

[0039] Adopting the vermicular graphite cast iron manufacturing method of the present invention to produce the diesel engine cylinder head made of vermicular graphite cast iron material greatly improves the service life of the cylinder head, eliminates the phenomenon...

Embodiment 3

[0041] Use a medium frequency induction furnace with a capacity of 2 tons to smelt molten iron, use nodular cast iron, use a direct-reading spectrometer to quickly analyze the chemical composition of the molten iron, and perform vermicular treatment by pouring the bag method. In this embodiment, the sulfur content of the original molten iron is 0.037%, and the added vermicular The inoculant is 0.70% of the total material mass, and the inoculant is 0.6% SiFe75 and 0.2% SiCa of the total material mass.

[0042] The composition of the vermicular agent is: 10% rhenium; 5% magnesium; 2% calcium; 2% aluminum; 42% silicon;

[0043] Adopting the vermicular graphite cast iron manufacturing method of the present invention to produce the diesel engine cylinder head made of vermicular graphite cast iron material greatly improves the service life of the cylinder head, eliminates the phenomenon of fatigue cracks in the cylinder head during the warranty period of the diesel engine, and makes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com