Method for producing high puriy, laminar cast ingot of Nd-Fe-B alloys

A technology of alloy ingot casting and production method, which is applied in the direction of magnetic materials, electrical components, circuits, etc., can solve the problems affecting the performance of NdFeB alloys, coarse grains, composition inclusions, etc., and achieve grain refinement, ingot density increase, Effect of component segregation suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

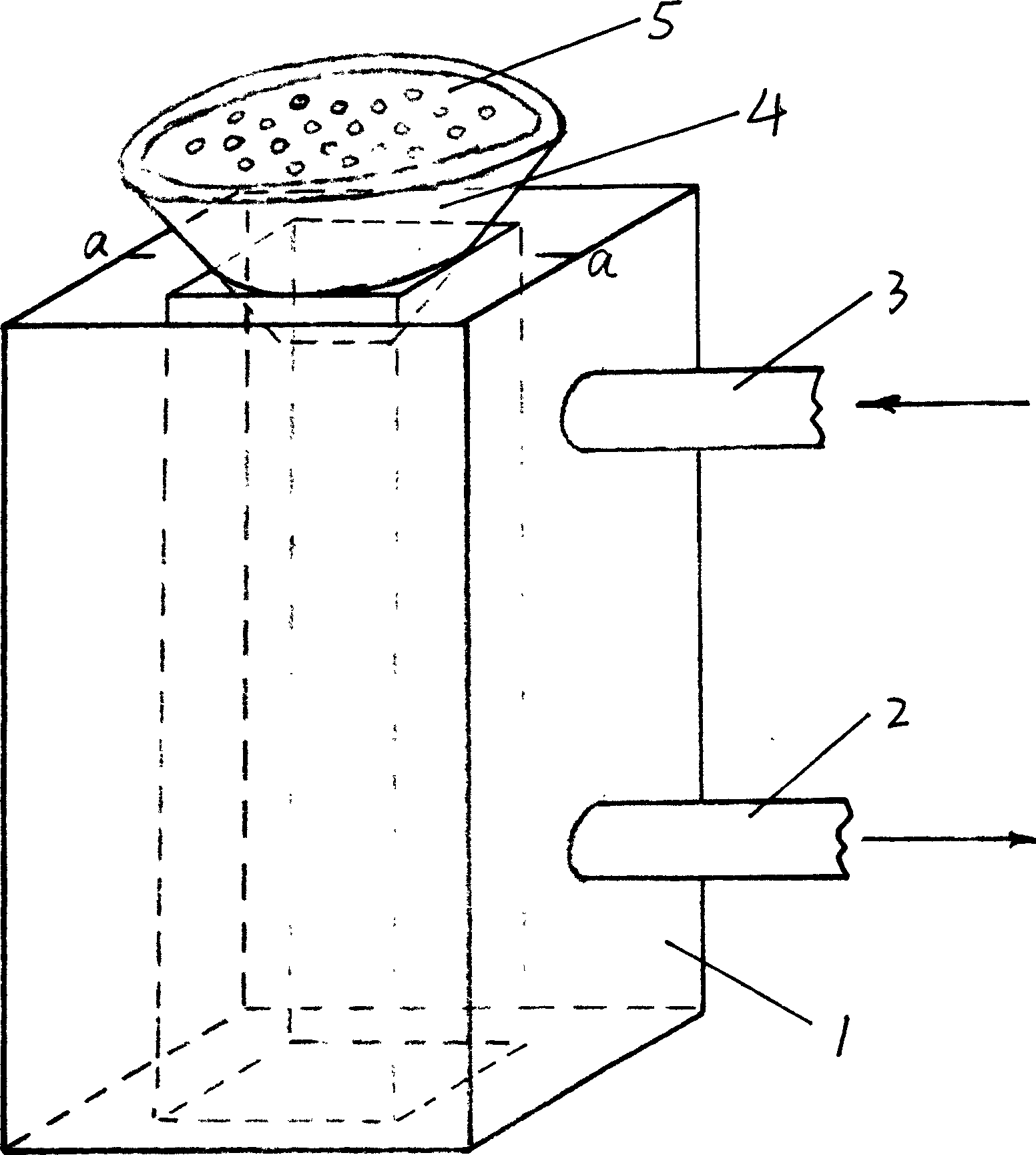

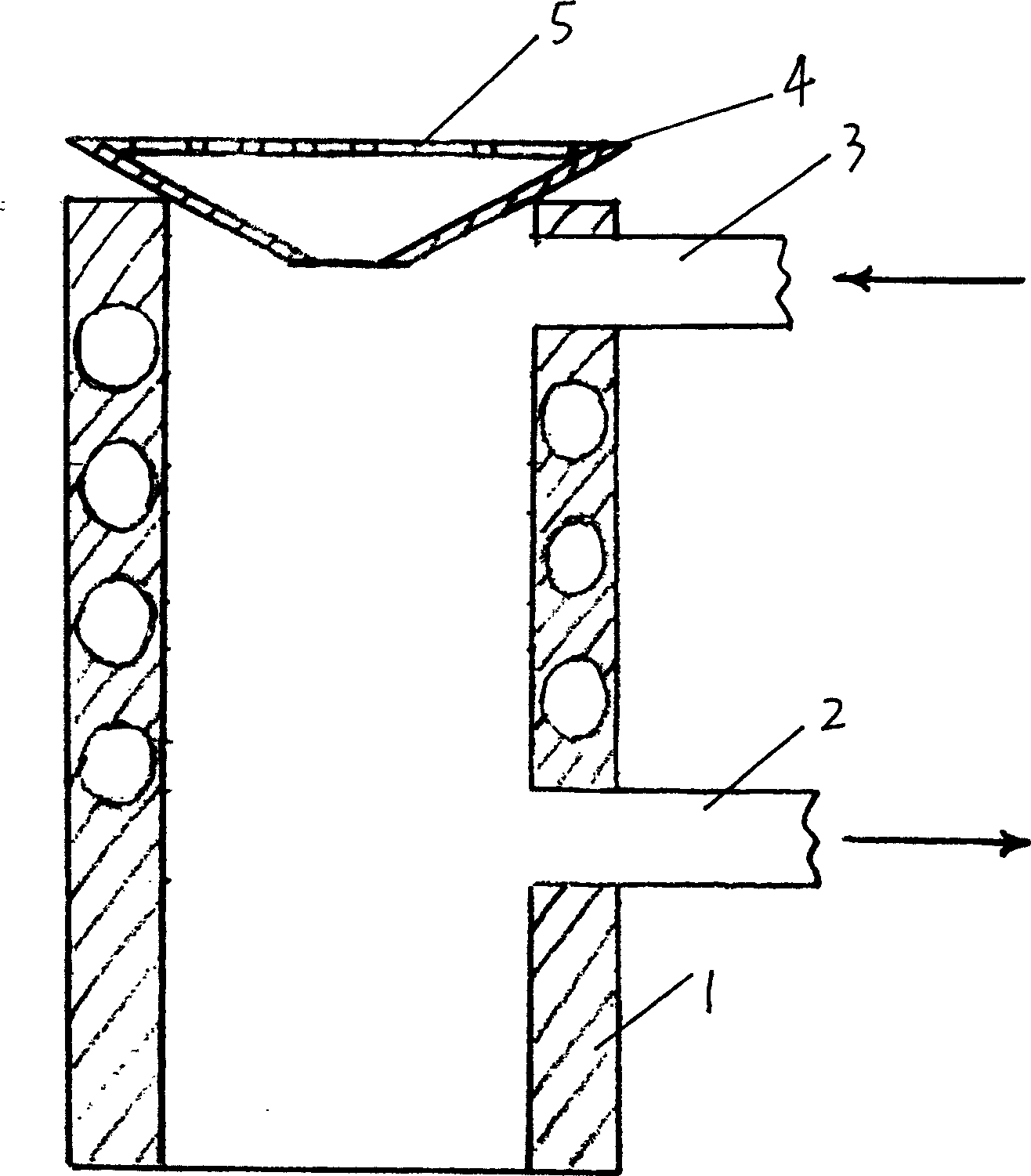

Method used

Image

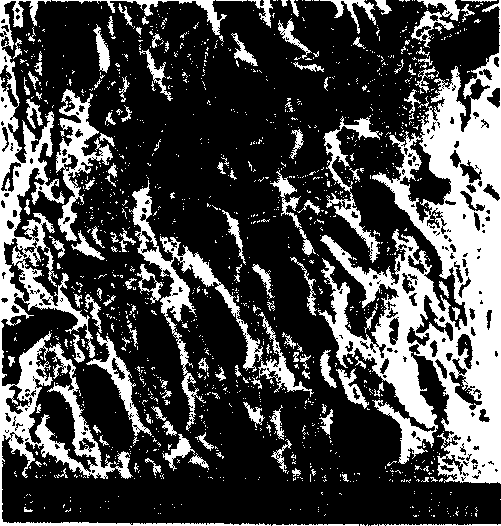

Examples

Embodiment 1

[0028] The composition of this embodiment is Nd 10.5 Fe 76.4 co 5 Zr 2 B 6.1 alloy ingot, the process steps are as follows:

[0029] (1) Ingredients

[0030] Industrial pure iron 53.5%

[0031] Boron iron (19.53% boron content) 29.0%

[0034] Sponge metal zirconium 2%

[0035] The above are percentages by weight.

[0036] (2) Melting

[0037] The melting equipment is a 20kg vacuum melting furnace. Put the NdFeB alloy material into the crucible, hang the calcium-magnesium alloy above the crucible, and seal the furnace body to draw a vacuum. When the vacuum reaches 8×10 -2 Pa, fill it with argon to 0.05Mpa, and then start smelting, and the temperature is controlled at about 1500°C during smelting. After each component of NdFeB alloy is fully melted, add calcium-magnesium alloy to purify the melt, the addition of calcium-magnesium alloy is 0.2% (percentage by weight) of the total amount of each component in the...

Embodiment 2

[0059] This embodiment makes Nd 32.8 Fe 66.1 B 1.1 Alloy ingot, the process steps are as follows:

[0060] (1) Ingredients

[0061] Industrial pure iron 38.2%

[0062] Boron iron (19.53% boron content) 29.0%

[0064] The above are percentages by weight.

[0065] (2) Melting

[0066] The smelting equipment is a 20kg vacuum smelting furnace. The smelting process parameters and operation are the same as in Example 1. After the components of the NdFeB alloy are fully melted, metal calcium is added to purify the melt. 0.5% (percentage by weight) of the total amount. The specific operation is: suspend the calcium metal block above the crucible, and after the components of the NdFeB alloy are fully melted, manipulate the handle of the crucible to raise the crucible so that the calcium metal is melted in the alloy liquid.

[0067] (3) Pouring

[0068] The ingot mold is made of copper, and its size is 180mm×150mm×30mm. Both sides of the ingot mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com