Method for preparing shell for investment casting and shell

A technology for investment casting and preparation steps, which is applied in the field of shell preparation for investment casting, and can solve problems such as inability to brush to areas of concern, inability to accurately control the quality of brushed slurry, uneven shell thickness, etc., to achieve shrinkage porosity The effect of reduced tendency, low cost, and uniform grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

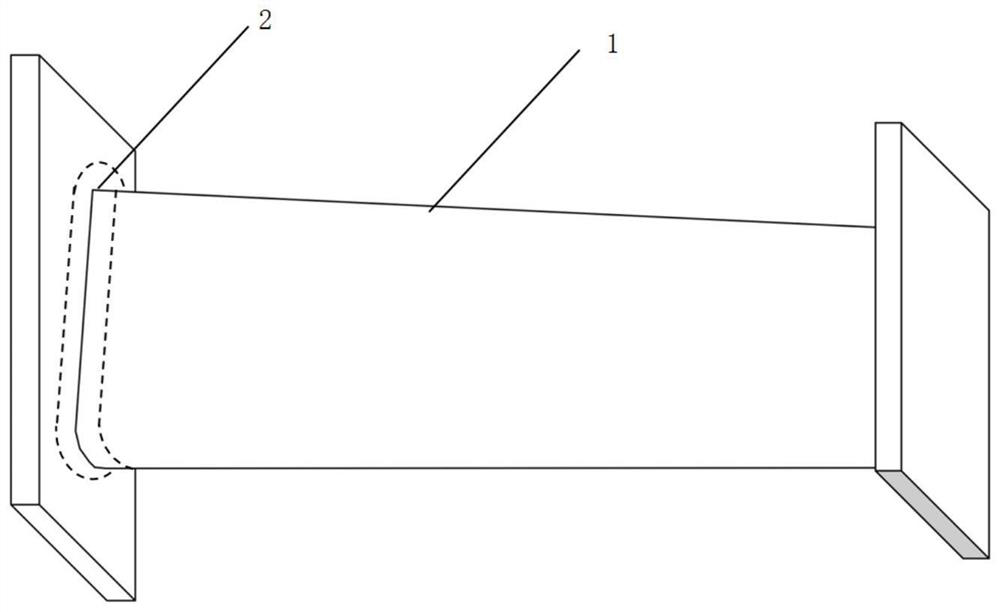

[0042] A method for preparing a mold shell for investment casting, comprising more than two shell preparation steps, at least part of the shell preparation steps include a slurry coating step, a sand shower step and a drying step, that is, repeated on the surface of a wax piece A plurality of shell layer preparation steps including a slurry coating step, a sand shower step and a drying step form a gradual accumulation of multiple shell layers on the surface of the wax piece. The final number of layers of the shell can be determined according to the size, shape and structure of the part.

[0043]According to the different raw materials and processes used, the shell layer preparation steps can be sequential surface layer preparation steps, transition layer preparation steps and reinforcement layer preparation steps, wherein the surface layer preparation steps, transition layer preparation steps and reinforcement layer The preparation steps can be repeated multiple times; corresp...

Embodiment 2

[0052] A method for preparing a mold shell for investment casting, comprising more than two shell preparation steps, at least part of the shell preparation steps include a slurry coating step, a sand shower step and a drying step, that is, repeated on the surface of a wax piece A plurality of shell layer preparation steps including a slurry coating step, a sand shower step and a drying step form a gradual accumulation of multiple shell layers on the surface of the wax piece. The final number of layers of the shell can be determined according to the size, shape and structure of the part.

[0053] According to the different raw materials and processes used, the shell layer preparation steps can be sequential surface layer preparation steps, transition layer preparation steps and reinforcement layer preparation steps, wherein the surface layer preparation steps, transition layer preparation steps and reinforcement layer The preparation steps can be repeated multiple times; corres...

Embodiment 3

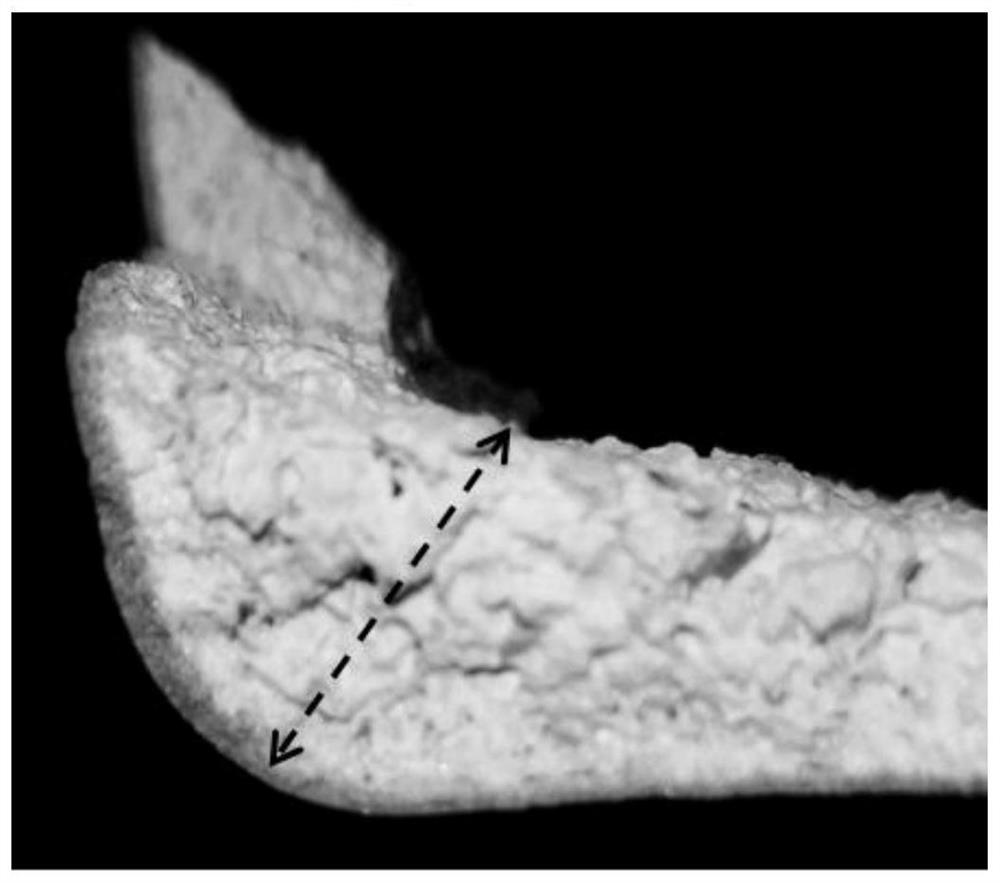

[0063] This embodiment provides the gas turbine turbine blade shell prepared according to the method for preparing the shell for investment casting in Example 1, and the thickness of the part on the shell corresponding to the hot spot of the casting is different from the thickness of other parts of the shell The deviation is less than 30%. Preferably, the deviation of the thickness of the part on the mold shell corresponding to the hot spot of the casting is less than 20% from the thickness of other parts of the mold shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com