Electric furnace smelting high-strength medium heat-resistant alloy cast iron and smelting method thereof

An electric furnace smelting and heat-resistant alloy technology, applied in the field of cast iron production, can solve the problems of inability to extend the internal feeding channel of molten iron, inability to promote the growth of equiaxed crystals, and increase manufacturing costs, so as to promote the growth of equiaxed crystals and ensure the installation test. The effect of pressure-free leakage and improving the performance of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

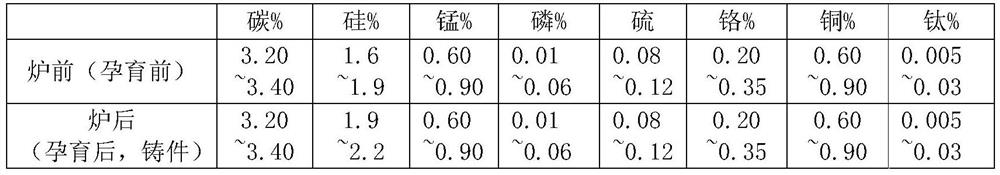

[0050] The smelting method provided by this application is used to prepare the castings shown in the table below, and the proportioning of each component of the castings is as follows in terms of chemically pure content:

[0051] Table 1: Contents of elements in castings

[0052]

[0053] The castings are smelted with steel scrap, returned charge and recarburizer as raw materials, and the batching scheme is shown in the following table:

[0054] Table 2: Raw material batching scheme

[0055] Program Scrap % Return charge % Carburizer% plan 1 60 40 2.3 Scenario 2 70 30 2.7 Option 3 75 25 2.9

[0056] Described smelting concrete steps are:

[0057] a. Put 40% of the total amount of steel scrap into the electric furnace for smelting;

[0058] b. When 1 / 3 of the scrap steel is melted, add recarburizer, iron sulfur and ferrosilicon in proportion, and reserve 0.3% of ferrosilicon and recarburizer;

[0059] c. Add the remaining scrap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com