Shoe mold, sole and method for molding sole on upper

A technology for shoe molds and uppers, which is applied in the field of shoe molds, soles and molding soles to uppers. It can solve problems such as limited access to accessories, difficult processing, and impact on product quality, so as to achieve soft and comfortable soles, avoid hydrolysis, and bond firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

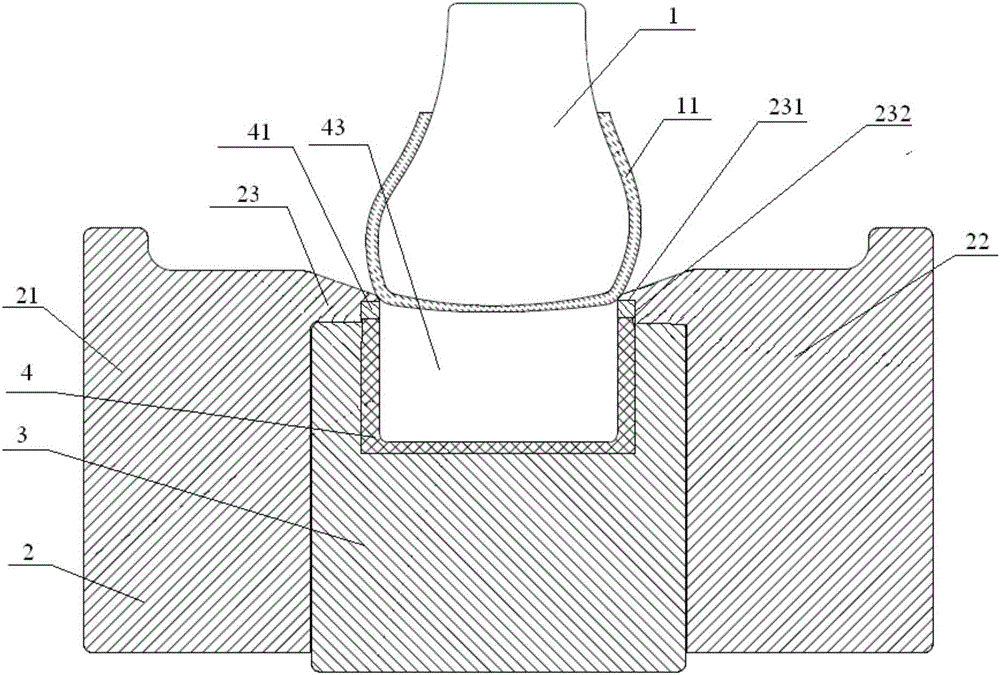

[0053] See Figure 1-2 , The present invention discloses a shoe mold, which includes a shoe last 1, an upper mold 2 and a lower mold 3. Among them, the shoe last 1 is the mother body of the shoe, and is the shoe forming mold, and the shoe last 1 can be replaced with any shoe last 1 required for the shoe to be manufactured. In this embodiment, the shoe last 1 is provided with an upper 11. The lower mold 3 can move along the vertical direction to close and separate with the upper mold 2, and the upper mold 2 is provided with an injection hole for injecting liquid injection plastic.

[0054] The upper mold 2 includes a first half body 21 and a second half body 22. The first half body 21 and the second half body 22 are symmetrically arranged so that the first half body 21 and the second half body 22 can be combined with the lower body The mold 3 is matched, that is, the upper mold 2 is divided into two halves along the longitudinal middle plane. The first half body 21 and the second...

Embodiment 2

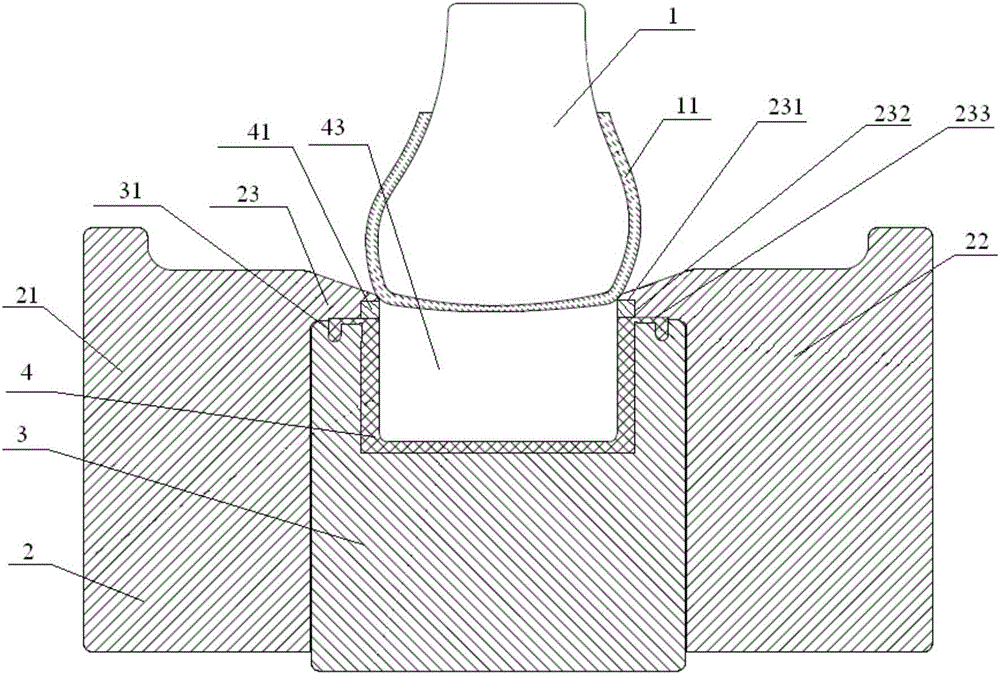

[0061] See Figure 3-6 In another embodiment provided by the present invention, the structure of the shoe mold in this embodiment is similar to that of the shoe mold in the first embodiment, and the similarities are not repeated here, and only the differences are introduced.

[0062] In this embodiment, it is specifically disclosed that the clamping portion 23 can abut the shoe welt 41. The arrangement of the clamping portion 23 enables the shoe edge strip 41 to abut the shoe upper 11 stably, avoiding a gap between the shoe edge strip 41 and the shoe upper 11, which causes the liquid injection plastic to overflow. The clamping portion 23 is provided with a first pressure surface 231 and a second pressure surface 232. The first pressure surface 231 can press the top surface 411 of the shoe welt 41, and the second pressure surface 232 can press the outer surface of the shoe welt 41. Side 412. Among them, the top surface 411 of the shoe edge 41 refers to the end surface of the shoe...

Embodiment 3

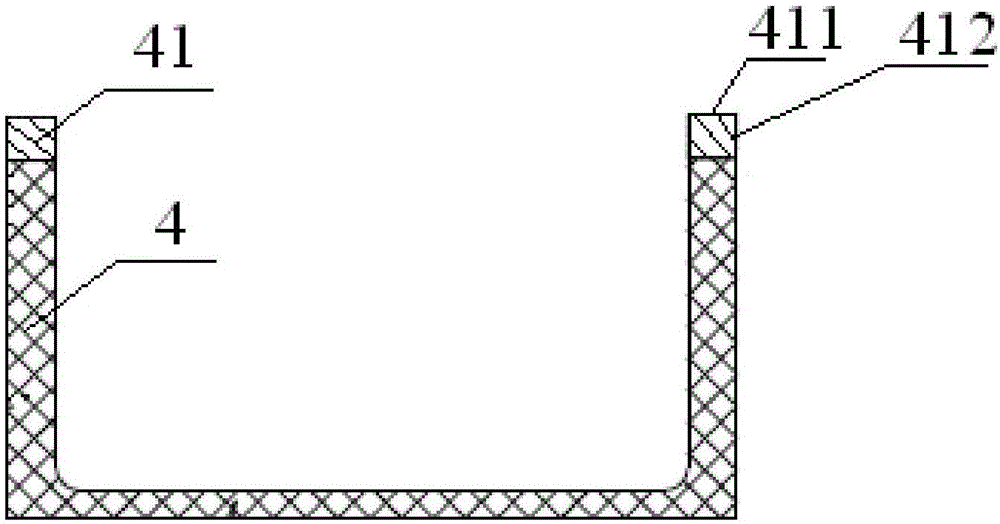

[0070] See Figure 7-Figure 8 The present invention provides a shoe sole. A shoe welt 41 is provided on the top of the shoe sole 4, wherein the shoe welt 41 can be integrally injection molded with the sole 4, or can be connected in other ways, which is not limited here. The sole 4 is bonded to the upper 11 through a shoe mold. The lower mold 3 of the shoe mold is provided with a cavity for placing the sole 4, and the upper mold 2 of the shoe mold is provided with a clamping portion 23 for clamping the shoe welt 41. When the upper mold 2 of the shoe mold is closed with the lower mold 3 mounted with the sole 4, the projection of the outer contour of the lower end of the upper 11 on the shoe last 1 in the direction of the lower mold 3 coincides with the inner contour of the shoe along the strip 41, and the shoe The top end of the rib 41 abuts on the upper 11.

[0071] In the sole 4 disclosed in the present invention, since the sole 4 is provided with a hanging edge 42, the hanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com