Extrusion method and die achieving synergistic effect of ultrasonic vibration and uniform tensile stress

A technology of ultrasonic vibration and tensile stress, which is applied in the field of molding processing methods and dies of polymer material extrusion products, can solve the problem of restricting the effect of ultrasonic vibration, affecting the uniformity of blend melt and the mixing efficiency of shear laminar flow Low-level problems, achieve the effect of realizing green molding processing, promoting renewal rate, and reducing specific energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

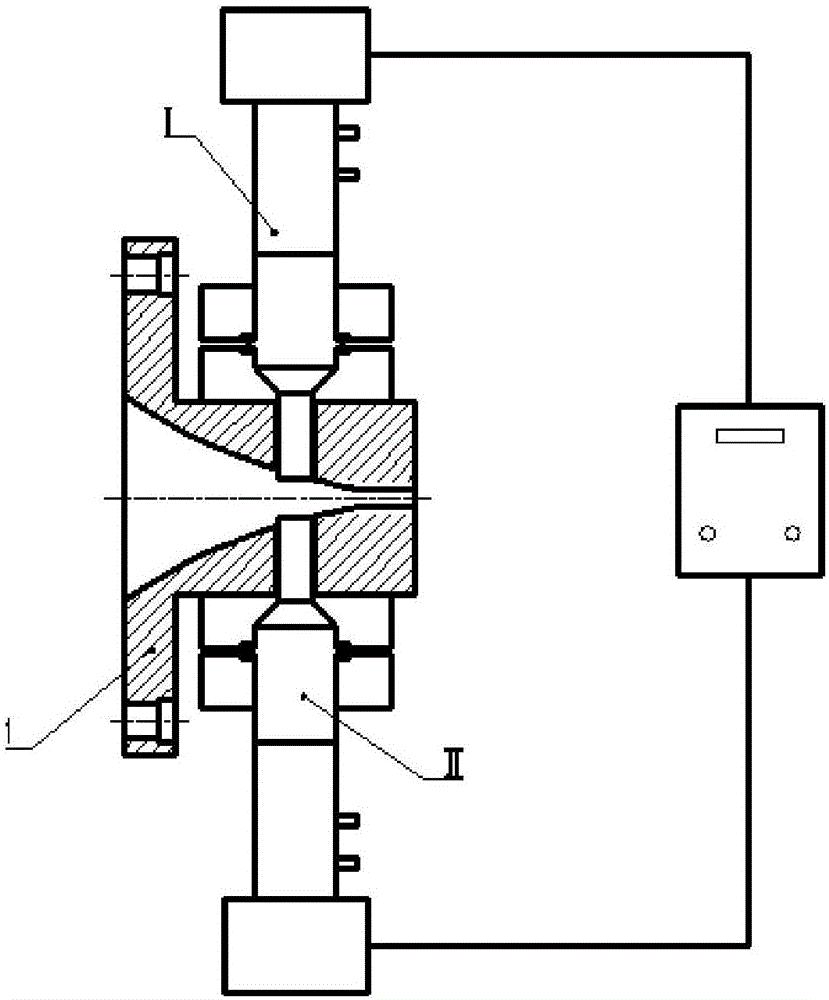

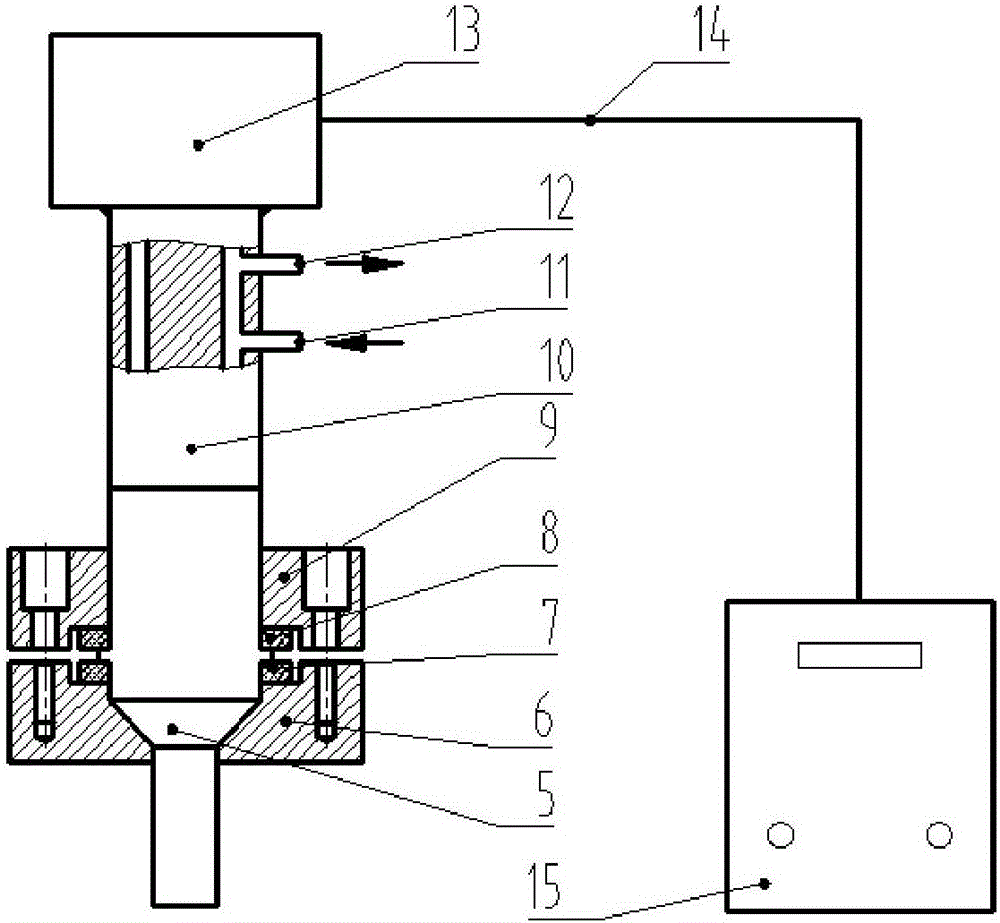

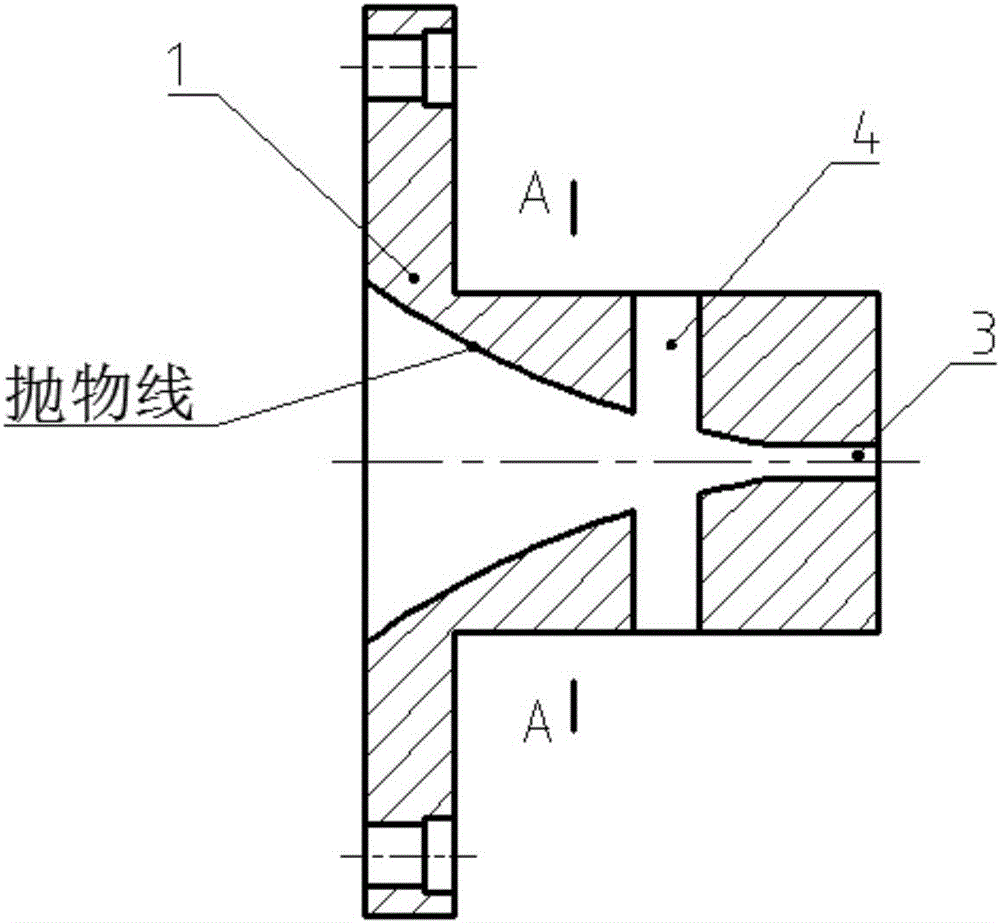

[0038] refer to figure 1 , figure 2 , image 3 , an extrusion die with synergistic effects of ultrasonic vibration and uniform tensile stress, including a die 1 with a parabolic convergent flow channel, a first ultrasonic vibration device I and a second ultrasonic vibration device II; the first ultrasonic vibration device and the second ultrasonic vibration device Two ultrasonic vibration devices are arranged symmetrically on both sides of the die. For the extrusion molding of rod products, the inlet and outlet of the flow channel are circular, and its generatrix is a parabola, which converges to the circular outlet through the parabola. The die 1 with a parabolic converging flow channel is connected to the flange of the extruder barrel through screws, and the ultrasonic vibration device I and the ultrasonic vibration device II are vertically fixed on the converging section of the die 1 with screws. The first ultrasonic vibration device I and the second ultrasonic vibrat...

Embodiment 2

[0046] For products with a rectangular cross-section, the inlet and outlet of the die flow channel are rectangular, the width direction remains unchanged, and the thickness direction along the generatrix is a hyperbola that gradually decreases to the thickness of the product. refer to figure 2 , image 3 , Figure 6 , Figure 7 , an extrusion die with synergistic effects of ultrasonic vibration and uniform tensile stress, comprising a die 1 with a parabolic converging flow channel, a first ultrasonic vibration device I and a second ultrasonic vibration device II. The die 1 with the hyperbolic converging channel is connected to the flange of the extruder barrel through screws, and the ultrasonic vibration device I and the ultrasonic vibration device II are vertically fixed on the converging section of the die 1 with screws.

[0047] The first ultrasonic vibration device I and the second ultrasonic vibration device II are mainly composed of a horn 5, a flange 6, a lower se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com