Preparation technology for honeycomb supporting structure

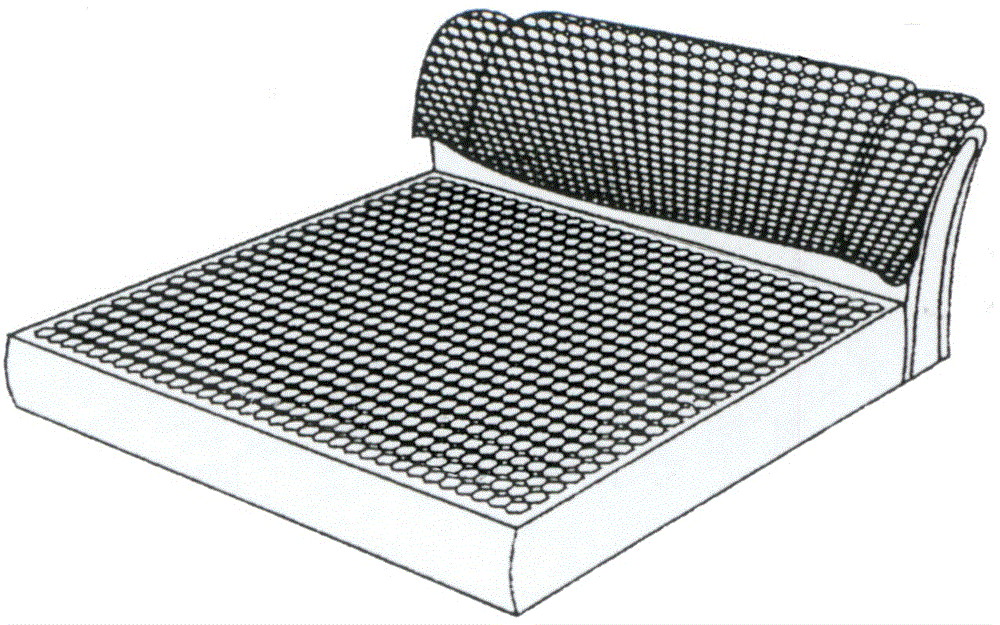

A technology of support structure and preparation process, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of short service life, poor support effect and stability, etc., to reduce production costs, simple structure, and realize industrialization. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation process for a honeycomb support structure, comprising:

[0034] Step 1. The plastic is prepared into a plate-shaped substrate through an extruder. In order to facilitate the setting of creases in the later stage, and considering the requirements for support strength, the thickness of the substrate in the present invention is preferably 0.5-5mm, and the thickness of the substrate is preferably 3 mm in this embodiment. mm. In this embodiment, the plastic can be selected from ordinary plastic materials, such as PVC, PP, PE or XPS; it can also be preferably a material with a melting point above 200° C., such as PC and ABS.

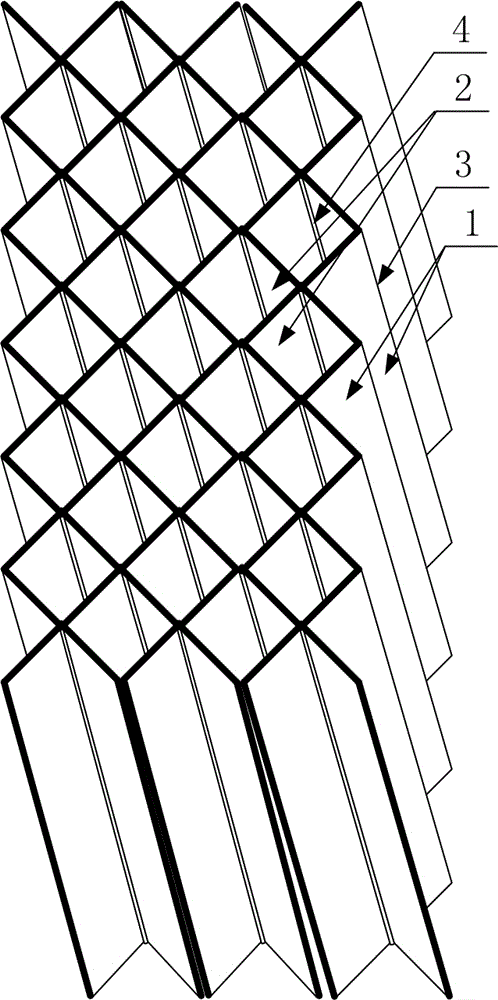

[0035] Step 2: Fold the plate-shaped base body by an edge-pressing machine to form creases, the base body can rotate along the creases, the folded creases are parallel to each other, and the distances between the creases are the same.

[0036] Step 3. Place more than two substrates in layers. When placing, the creases of two adjacent subs...

Embodiment 2

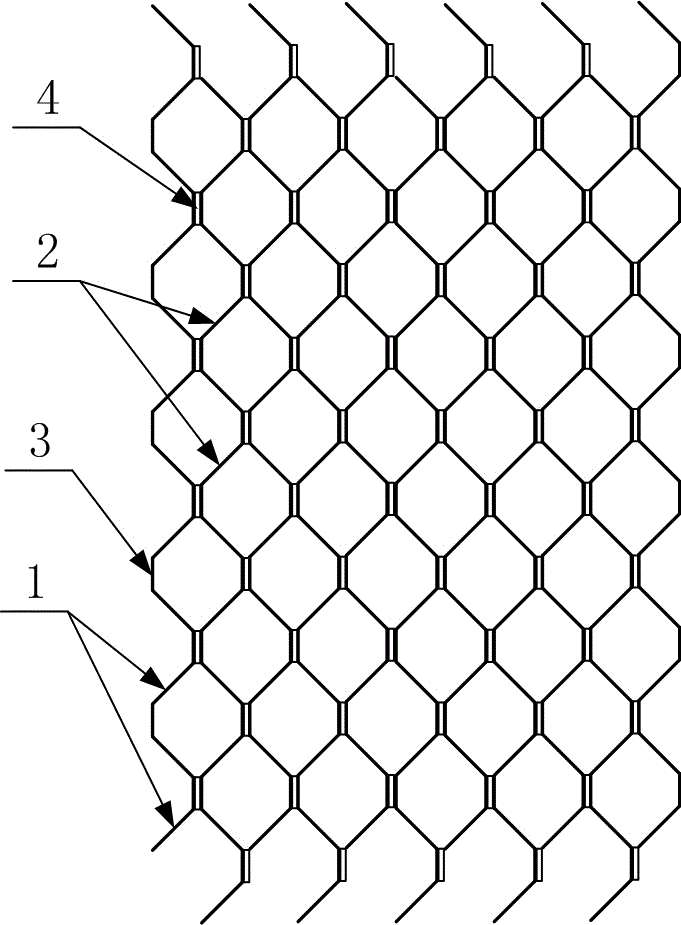

[0042] The difference between this embodiment and Embodiment 1 is that the settings of the creases in this embodiment are different, and the specific settings are as follows:

[0043] The creases on the substrate are all formed by two parallel folding lines, and a bonding plane is formed between the two folding lines, and the bonding plane is used to place bonding materials. Through the structure of this embodiment After setting, the finished product has a structure like figure 2 shown.

Embodiment 3

[0045] The difference between this embodiment and embodiment 2 is that the selection of the bonding material in this embodiment is different, and the specific settings are as follows:

[0046] In this embodiment, the bonding material does not use a thermal bonding material, but directly uses AB glue for fixing. When using AB glue for fixing, there is no need to reheat, and the AB glue can be dried naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com