Mini tiller, gearbox and steering mechanism thereof

A technology of steering mechanism and gearbox, which is applied in the field of gearboxes, and can solve the problems of large operating force of the separation mechanism, influence of output torque, and influence on return speed, etc., and achieve the effects of fast return speed, easy operation, and reduced operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments, and any improvement or replacement in the basic spirit of this embodiment still belongs to the claims of the present invention. scope.

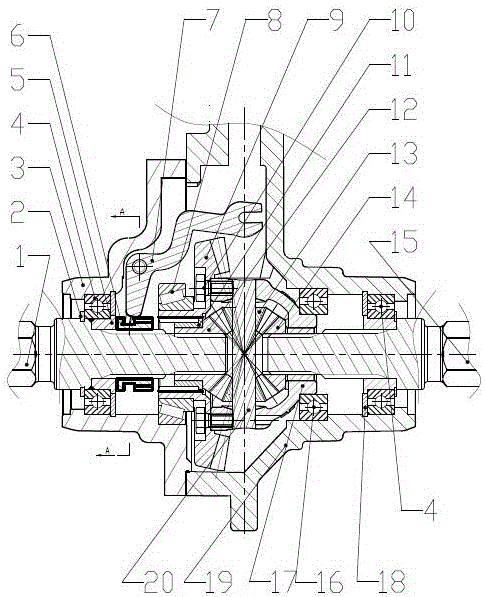

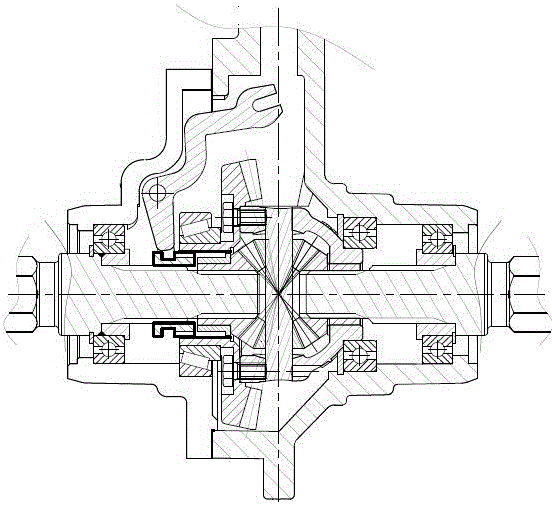

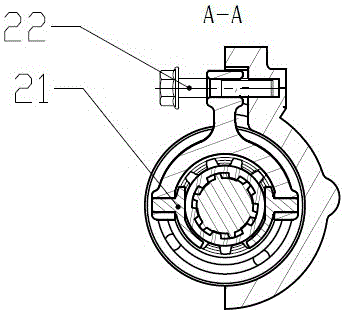

[0022] Example: such as Figure 1-4 As shown, a steering mechanism of a gearbox includes a left half shaft 1 and a right half shaft 15, and also includes a differential assembly; wherein, the differential assembly is composed of a left side gear 12, a left side gear Sleeve 11, right side shaft gear 14, planetary gear 13, planetary gear shaft 20 and differential case 17; the left side shaft gear 12 of the differential assembly is connected to the left side shaft 1 through a spline , the right side gear 14 of the differential assembly is connected to the right side shaft 15 through a spline. The steering mechanism also includes a driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com