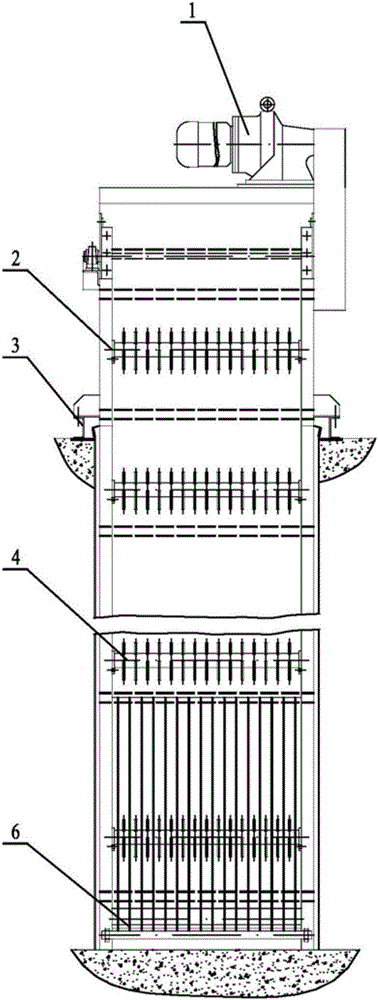

Rotary rake type grid dirt removing equipment

A grid decontamination and equipment technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of easy accumulation of debris on the grid, non-adjustable installation angle, attached grid Easy to clog and other problems, to achieve the effect of reducing labor intensity, reducing labor costs, and reducing cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

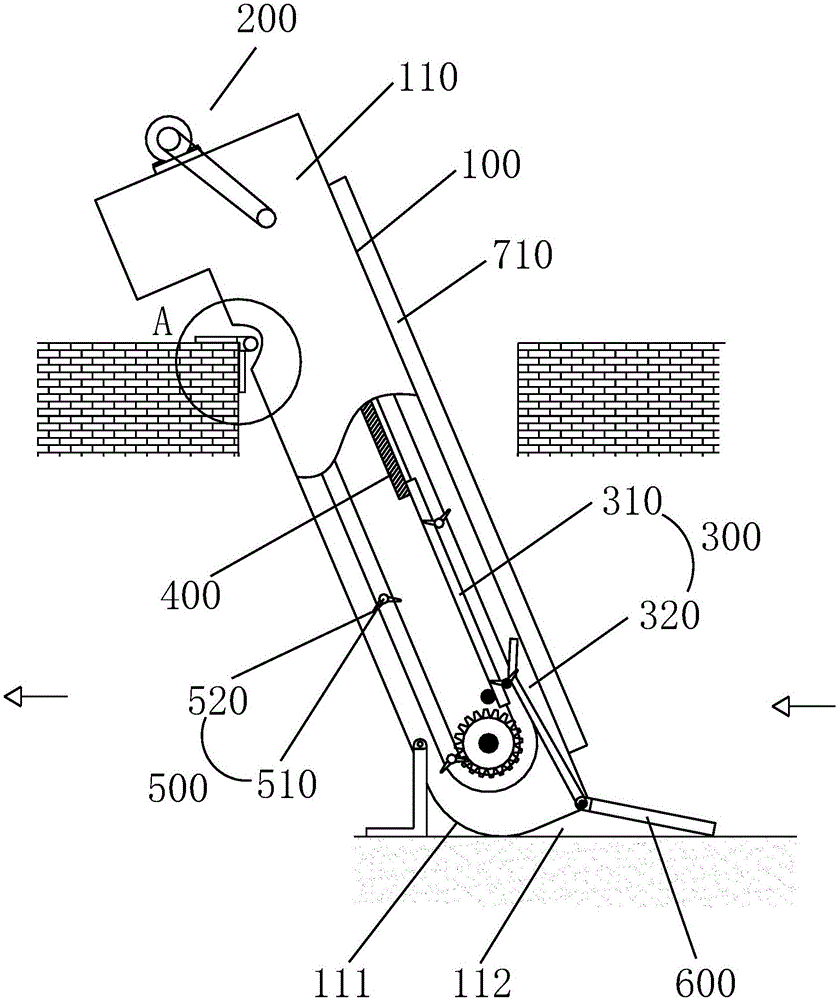

[0025] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

[0026] refer to Figure 3-4 with Image 6 , Figure 8 with Figure 9 , the present invention proposes a rotary rake type grid decontamination equipment, including a frame 100 and a slag blocking unit 300 arranged on the frame 100, and a slag scraping unit 700 is also arranged on the frame; wherein

[0027] The frame 100 includes two opposite side panels 110, the bottom edges of the two side panels 110 are at right angles to the front side edges, and the bottom edges of the two side panels 110 are excessively connected to the back side edges by an arc edge 111. ;

[0028] The slag blocking unit 300 is arranged at the middle and lower part of the frame 100, and includes a main grid body 310 and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com