Integrated stepping water-feeding type multistage A/O intensifying denitrification device

A point-by-point water inflow and denitrification technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as difficult unattended, poor biological denitrification effect The effects of small footprint, compact device structure, and simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0045] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

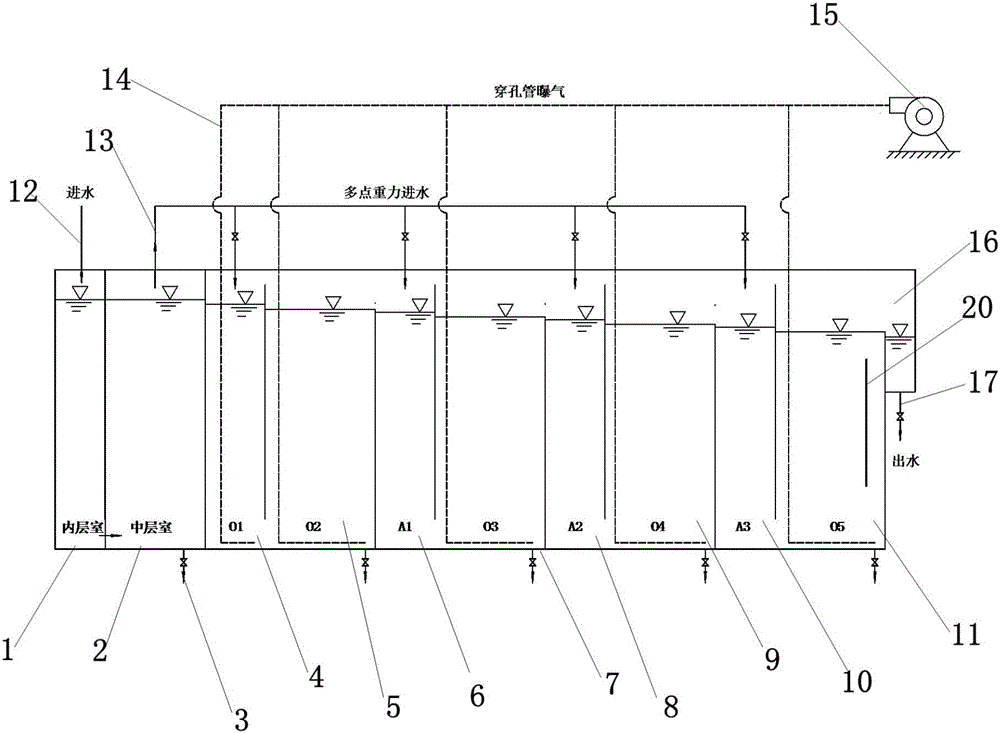

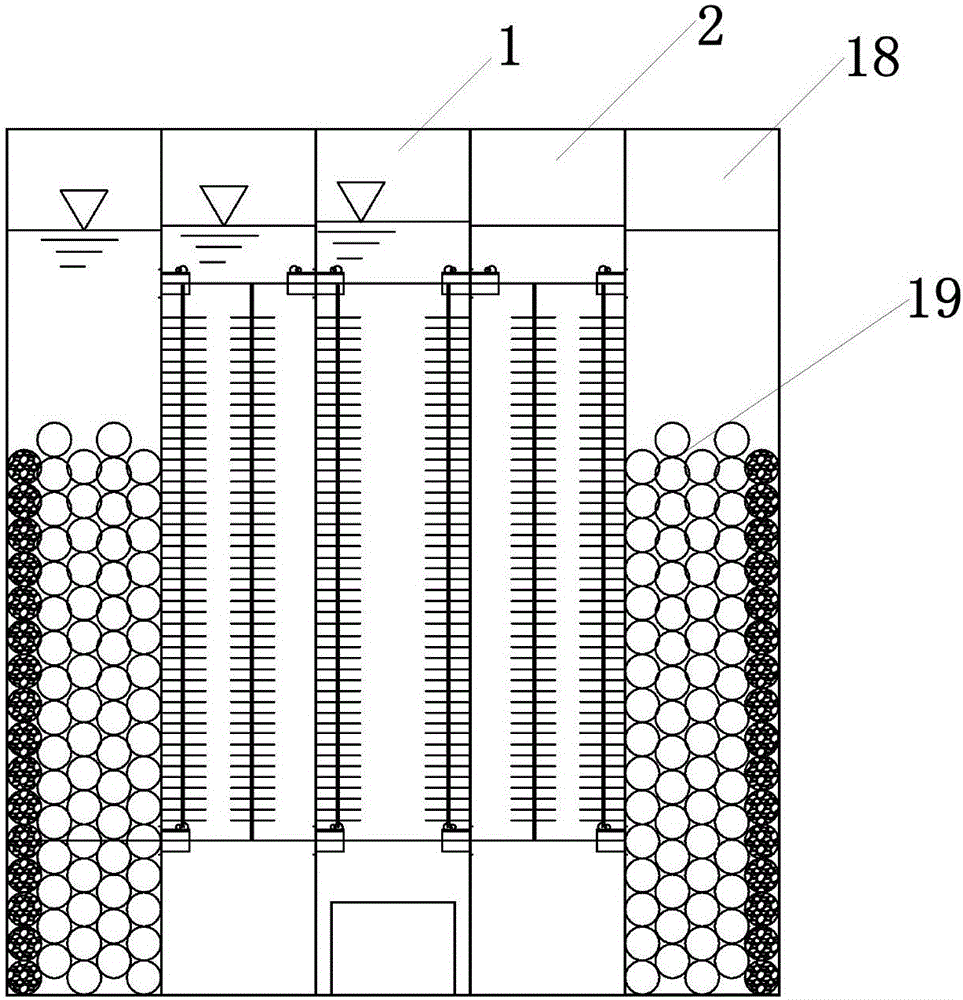

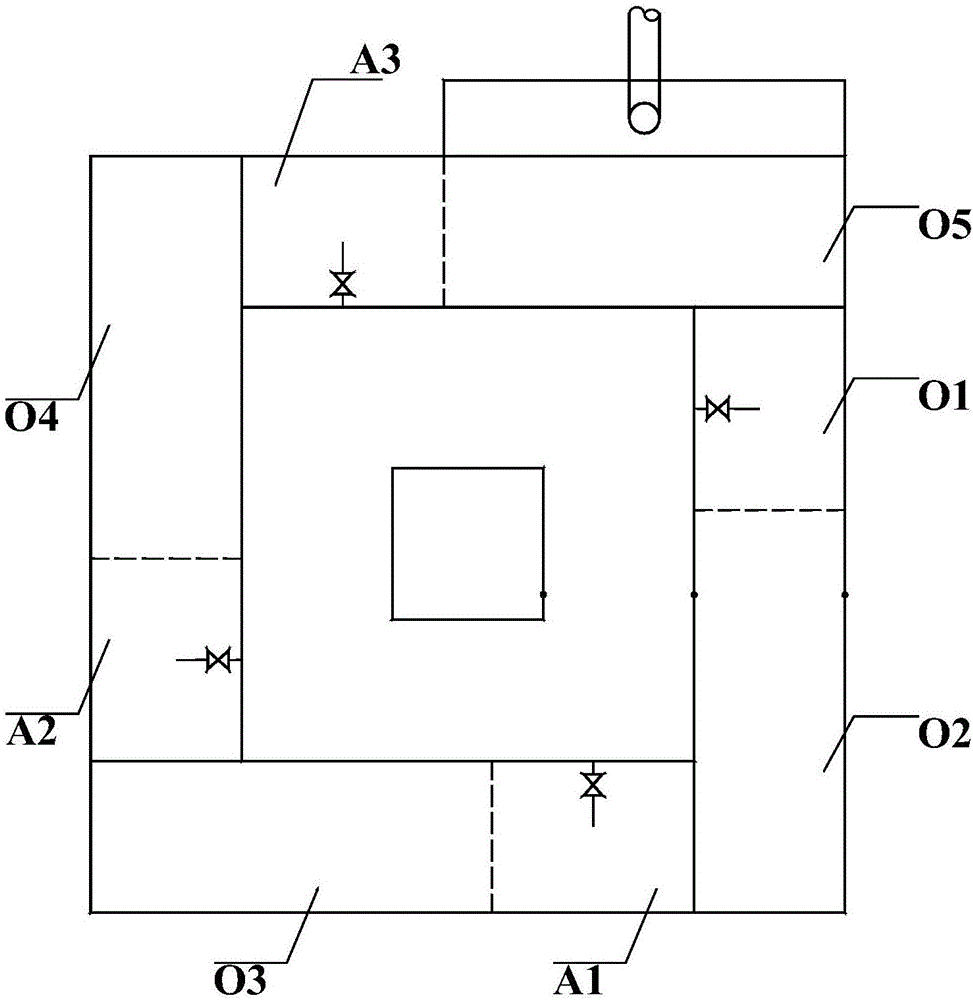

[0046] Such as Figure 1-Figure 3 As shown, the integrated split-point water-inflow multi-stage A / O enhanced denitrification device provided by the embodiment of the present invention includes: inner chamber 1, middle chamber 2, water discharge pipe 3, O1 aerobic zone 4, O2 aerobic zone 5. A1 anoxic zone 6, O3 aerobic zone 7, A2 anoxic zone 8, O4 aerobic zone 9, A3 anoxic zone 10, O5 aerobic zone 11, water inlet pipe 12, hydrolysis acidification outlet pipe 13, air pipe 14. Air pump 15, water outlet tank 16, water outlet pipe 17, outer layer chamber 18, drift ball 19.

[0047] A three-layer coaxial cuboid is used,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com