Lightweight partition wall

A lightweight partition board and wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of not energy saving and environmental protection, high cost, inconvenient construction, etc., to improve the use function and post-processing performance, flatness High, convenient and quick construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

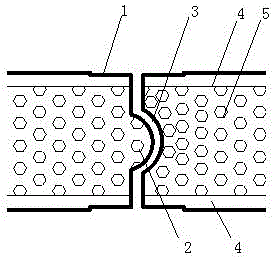

[0035] Such as figure 1 The section of the bump 2 and the groove 3 is trapezoidal, the length and width of the bump 2 are smaller than the depth and width of the groove 3 respectively, and the grouting port is formed after the bump 2 and the groove 3 are inserted.

Embodiment 2

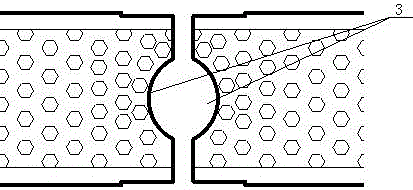

[0037] Such as figure 2 , the section of the bump 2 and the groove 3 is arc-shaped, and the grouting port is formed after the bump 2 and the groove 3 are inserted. A grouting opening is formed between the two grooves 3 in the two interconnected lightweight partition walls.

Embodiment 3

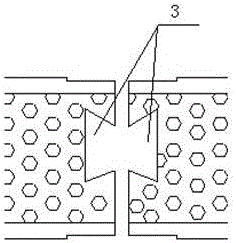

[0039] Such as image 3 The sections of the bump 2 and the groove 3 are arc-shaped, and the two grooves 3 connected to each other of the lightweight partition wall panels are oppositely arranged to form a grouting opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com