Vortex type receiver for electrostatic spinning, and method for preparing nano-fibers

A nanofiber and electrospinning technology, applied in fiber processing, textiles and papermaking, filament/wire forming, etc., can solve problems such as loose bonding, low structural strength, and collectors not being used as components of high-voltage electric fields, etc., to achieve The effect of dense and orderly structure and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

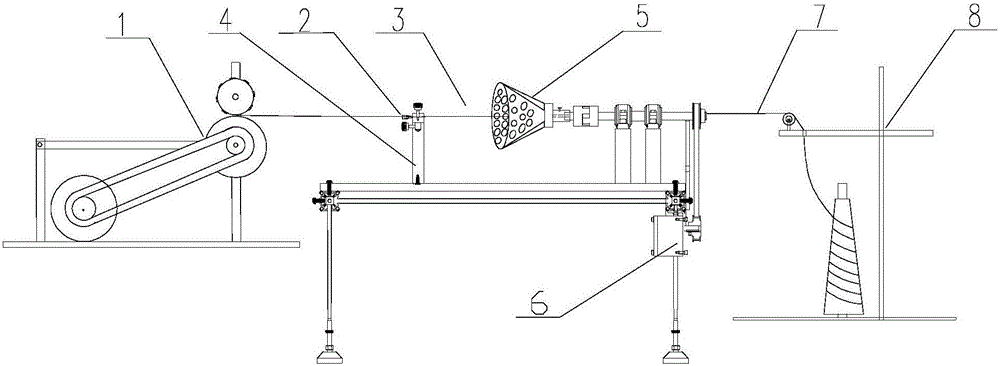

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0024] Electrospinning technology is based on the electrohydraulic movement of Taylor cones in an electrostatic field, stretching to form nanofibers, and the formed nanofibers are collected to form nanofiber aggregates. At present, the research on electrospinning is focused on the research on the injection device of solution or melt or the research on the fiber collection device, but there is still no method for preparing nanofiber aggregates with ordered structure.

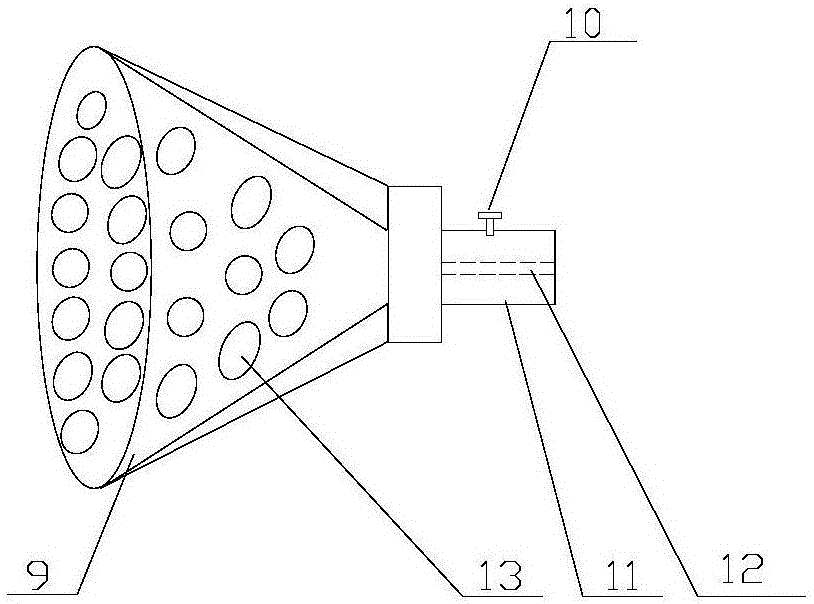

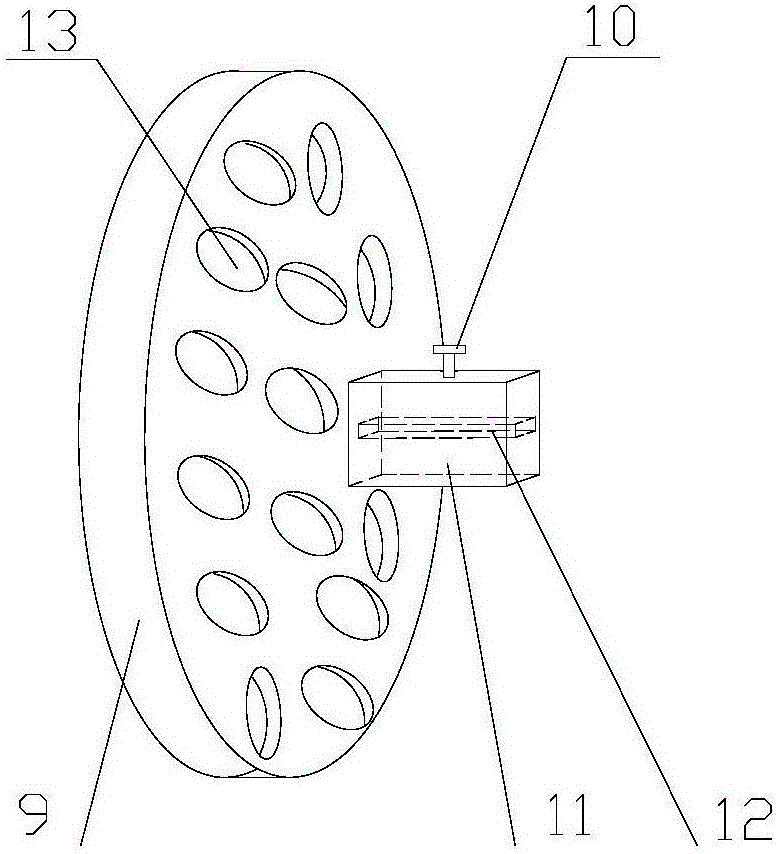

[0025] The present invention proposes to use the vortex receiver as an electrode for the electrostatic field of electrospinning, and the vortex receiver is provided with an airflow hole to keep the air pressure balance on both sides of the receiver, and keep the vortex receiver along the wire outlet device and The central axis of the connection between the vortex receivers rotates, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com