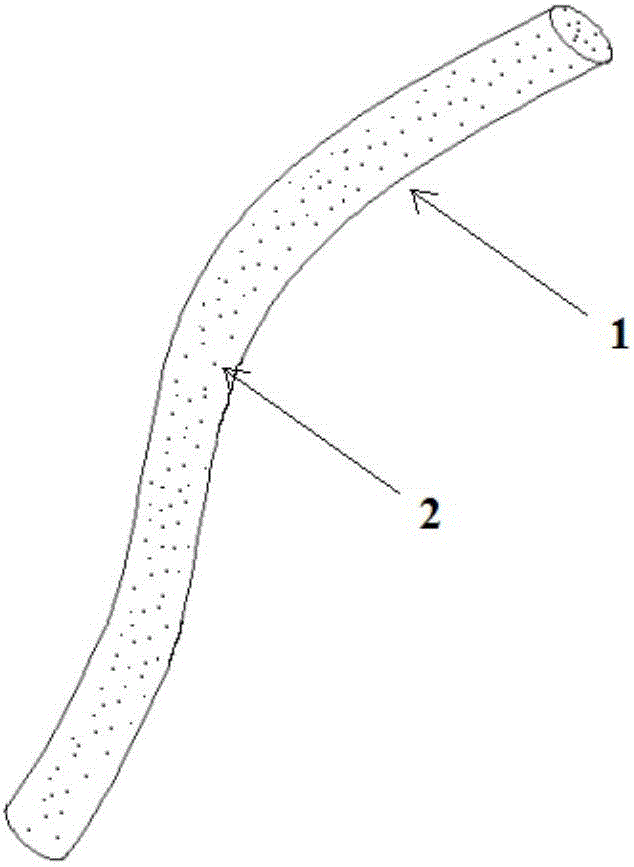

Polyester-cotton composite fabric with antibacterial and impermeable functions and preparation method thereof

A polyester-cotton composite, anti-penetration technology, applied in the field of textile fabrics and fabrics, can solve the problems of easy hydrolysis, short validity period, limited antibacterial effect, poor heat resistance, etc. The effect of wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Antibacterial masterbatch:

[0035]The antibacterial masterbatch antibacterial carrier and PET resin are prepared, and the porous silica gel carrier with nano-silver particles attached to it is uniformly mixed with PET, crushed into particles of about 1mm, and prepared by melting, twin-screw extrusion, cooling, and cutting. Among them, the particle size of nano-silver is: 1-100nm, and the specific surface area of porous silica gel is 350-500m 2 / g, the pore size is 10nm, and the particle range is 80-100 mesh. The mass ratio of nano silver and silica gel carrier is: 1:1. The mass ratio of antibacterial carrier and PET in antibacterial masterbatch: 1:10.

[0036] Antibacterial polyester fiber:

[0037] Polyester antibacterial fiber is uniformly mixed with PET and antibacterial masterbatch at a ratio of 10:1, melted at 275°C, spun at a speed of 1200m / min, and the diameter of the single filament is controlled at about 25μm.

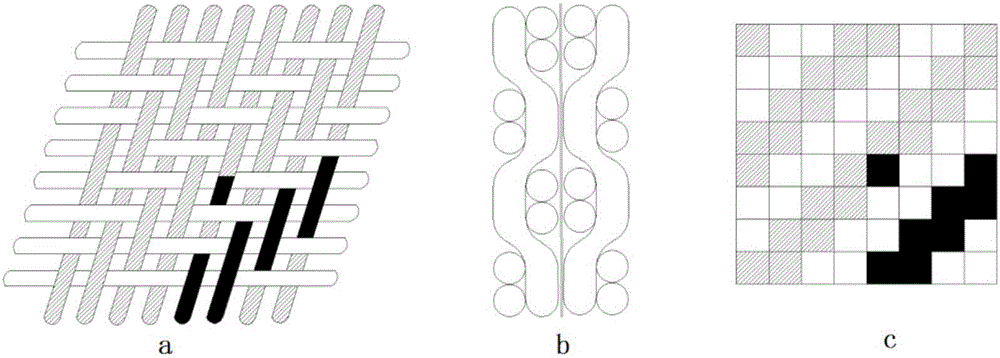

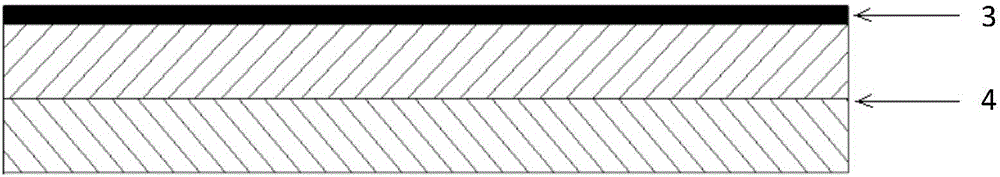

[0038] Polyester-cotton composite double-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap