A sock shaping device

A technology for socks and equipment, applied in the field of sock shaping and shaping equipment, can solve problems such as inconvenience in the production process, and achieve the effects of efficient space, convenient maintenance, and stable movement paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

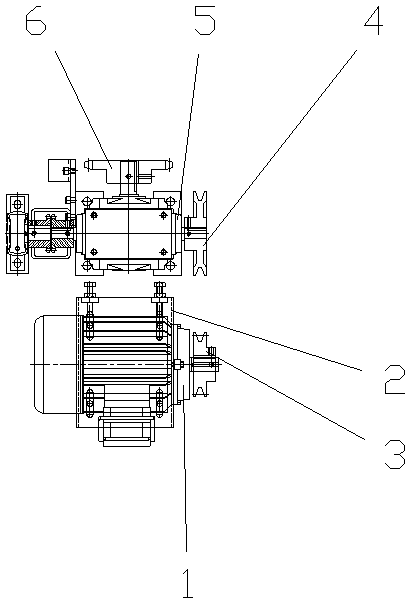

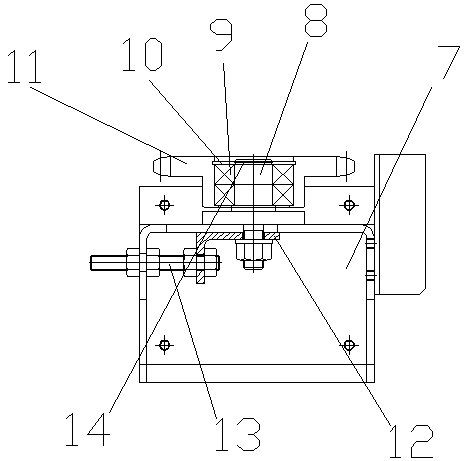

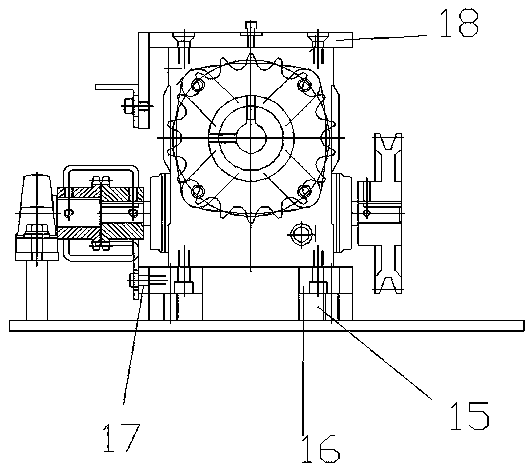

[0041] Combine below Figure 1-24 And embodiment further illustrate the present invention.

[0042] Push rod sprocket seat two 22, reducer two 21, push rod sprocket seat one 7, reducer one 5 are fixed on below the track successively from left to right. A push rod one 19 is arranged between the push rod sprocket seat one 7 and the reducer two 21, and a push rod two 20 is arranged between the reducer two 21 and the push rod sprocket seat two 22. A hook 23 is provided inside the track.

[0043] The reducer one 5 drives the transmission chain to move through the push rod reducer sprocket one 6, the reducer one 5 is fixed together with the motor one 1 by the motor seat one 2 using bolts, the reducer one 5 is provided with the reducer one pulley two 4, Motor one 1 is provided with speed reducer one pulley one 3, after speed reducer one 5 is fixed with motor one 1, speed reducer one pulley one 3 and speed reducer one pulley two 4 are on the same side. Reducer-pulley-3 and reducer-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com