Electric bypass valve

A bypass valve, electric technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of increased drilling risk and cost, large mud loss, extended drilling cycle, etc., to achieve simple structure, Reduce the number of trips, convenience and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

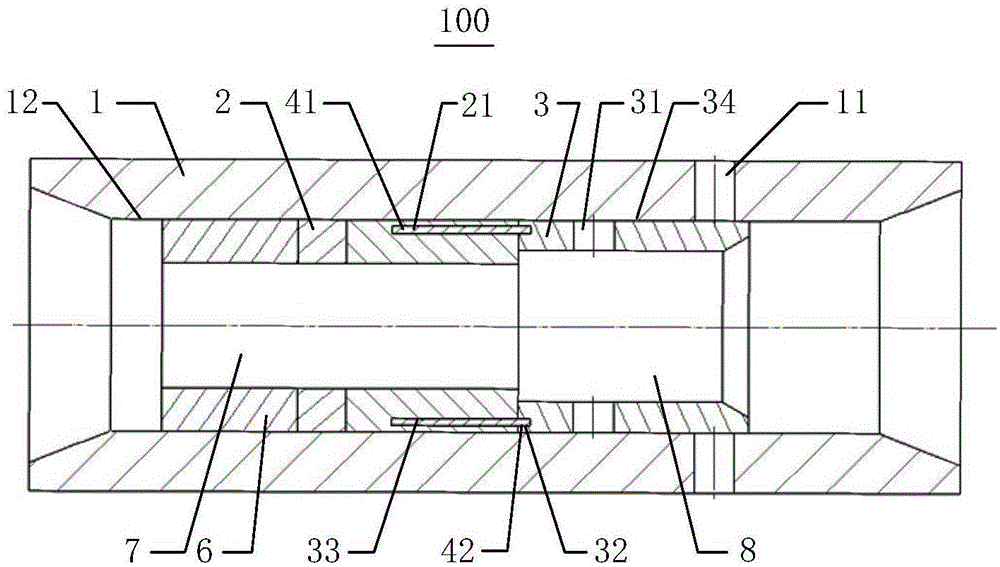

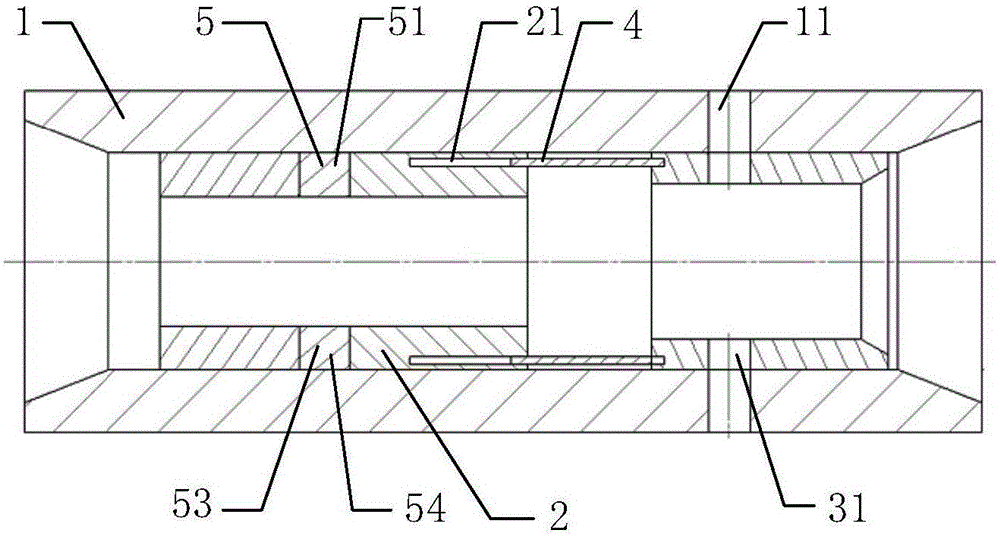

[0024] see figure 1 and figure 2 , which is a schematic diagram of the overall structure of the electric bypass valve according to the embodiment of the present invention. figure 1 It is schematically shown that the electric bypass valve 100 includes a valve body 1 , a driving motor 2 and a sliding sleeve 3 .

[0025] In the embodiment of the present application, the valve body 1 is approximately cylindrical and hollow inside. The valve body 1 needs to work underground for a long time, and the environment is relatively harsh, so the valve body 1 should have certain corrosion resistance and erosion resistance. In addition, since the valve body 1 needs to rotate along its own axial or circumferential direction downhole, the valve body 1 should also have certain properties of tensile and torsion resistance. Therefore, the valve body 1 should be made of corrosion-resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com