An on-axis component installation and cooperation structure

A matching structure and component installation technology, applied in the direction of couplings, engine components, rigid shaft couplings, etc., can solve problems such as complex design and constraint design, and achieve the effect of avoiding force damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

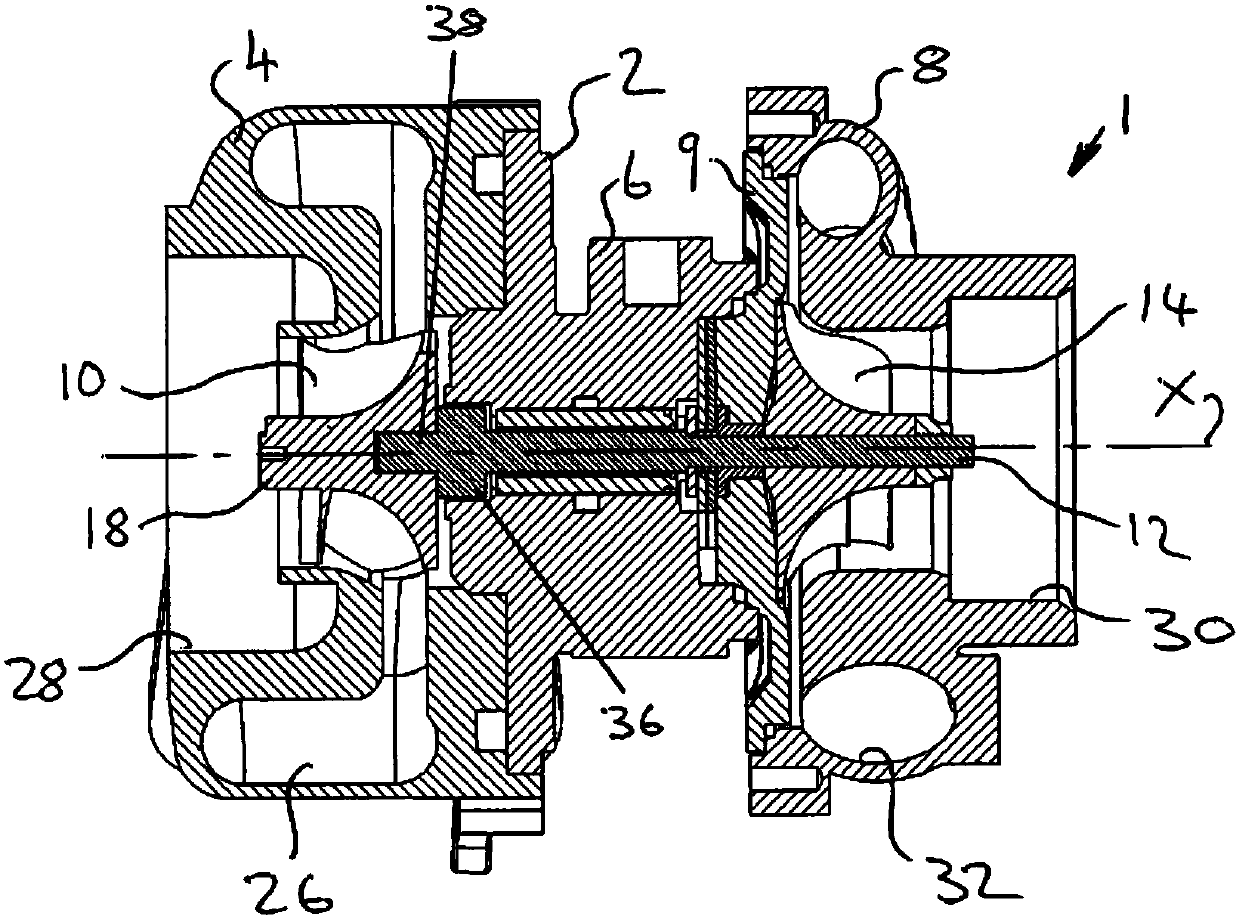

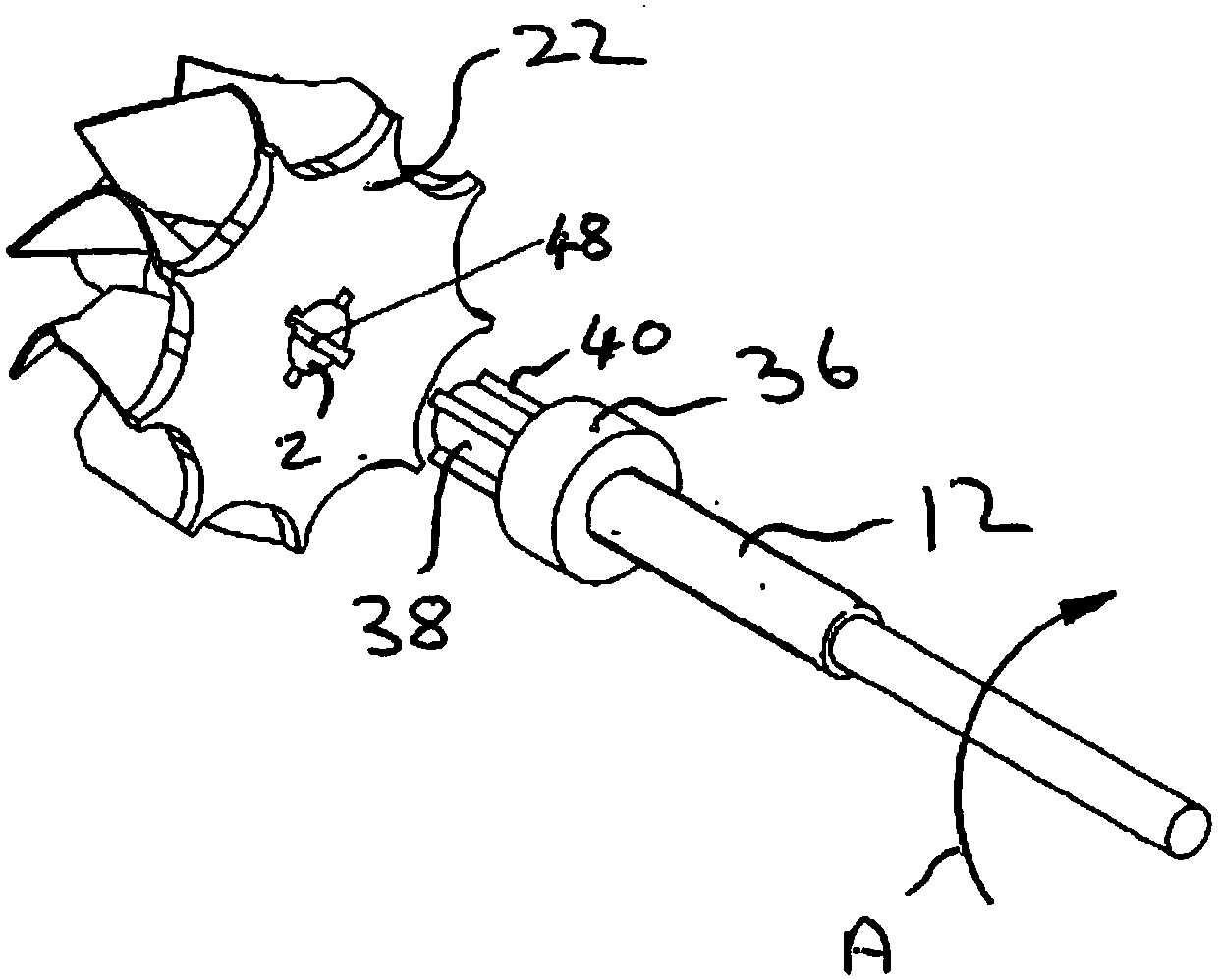

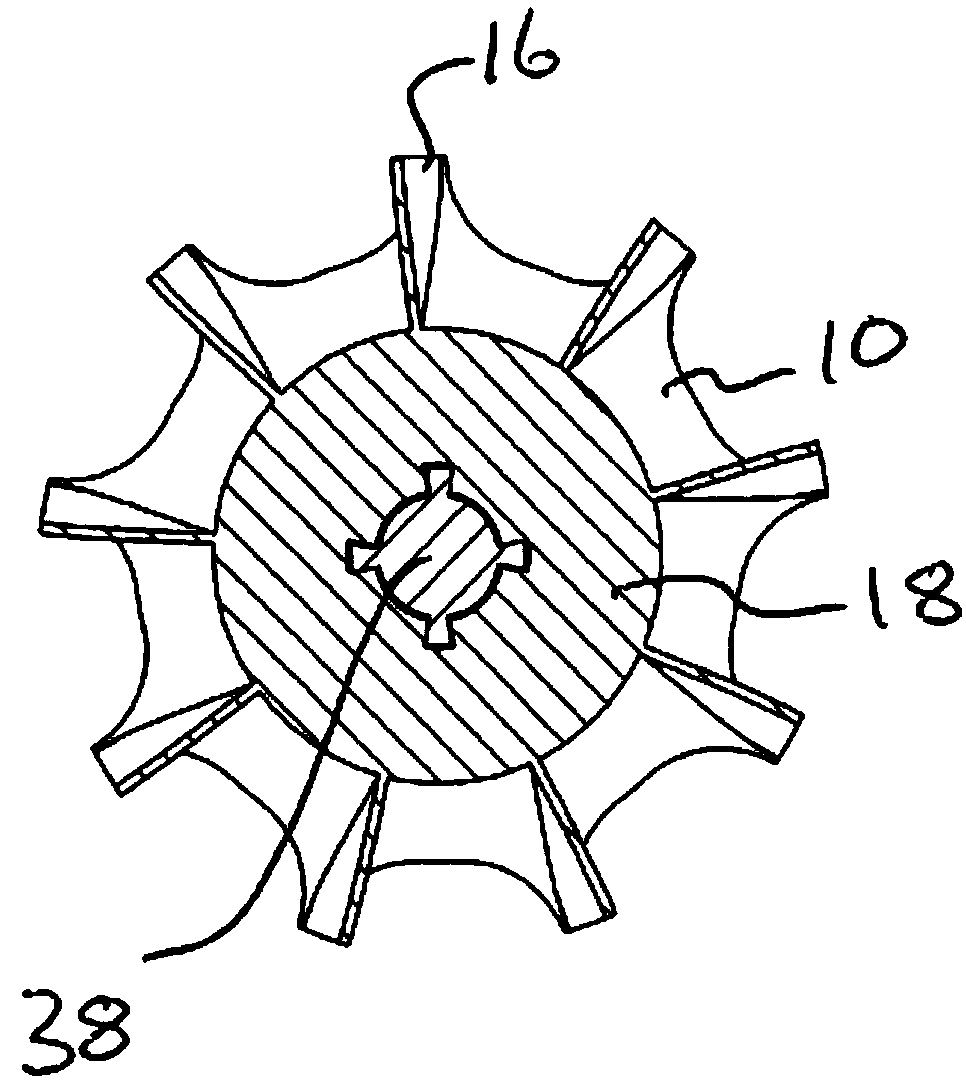

[0042] The installation and cooperation structure of the on-axis component of the present invention is as follows: an on-axis component that can rotate at a high speed and is installed on the shaft and rotates together with the shaft along the longitudinal axis of the shaft; the on-axis component has a surface that defines A central axial hole is at least partially passed through; the shaft component also includes at least 2 longitudinal keyways in the surface of the central axial hole, each keyway has an anterior surface and a caudal surface; the shaft A part extends into said central axial hole, the outer peripheral surface of this part of the shaft has a number of longitudinal keys corresponding to the number of key slots, each key has a front side surface and a tail side surface, and the keys fit into the corresponding key slots to form Key / keyway combinations; wherein, at least at room temperature, the keyways are wider than the keys, and each key is circumferentially offs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com