V-shaped safety connecting-rod mechanism for water guiding mechanism of through-flow turbine

A technology of a tubular water turbine and a water guide mechanism, which is applied in the directions of connecting rods, machines/engines, and reaction engines, can solve the problems of high cost and complex structure, and achieves a short time-consuming, low manufacturing cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

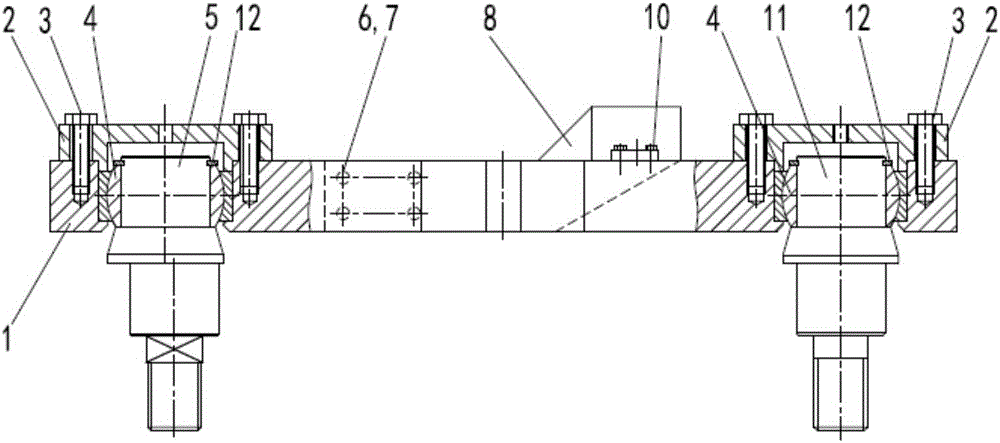

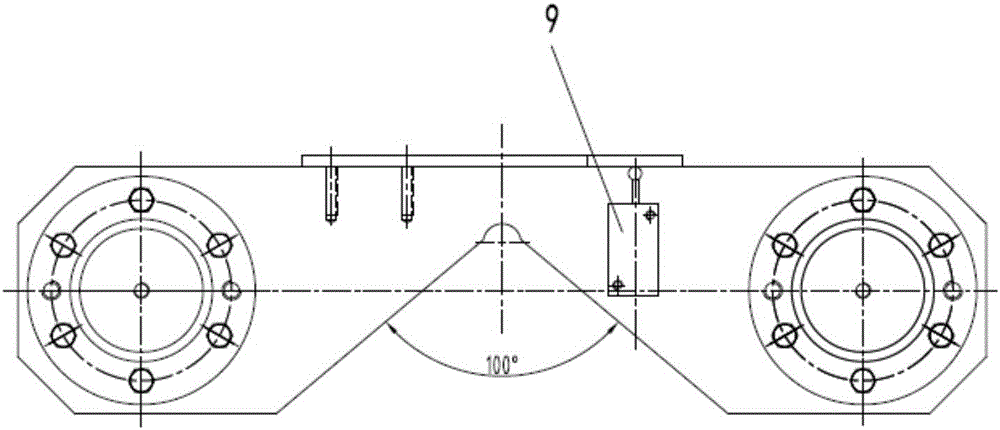

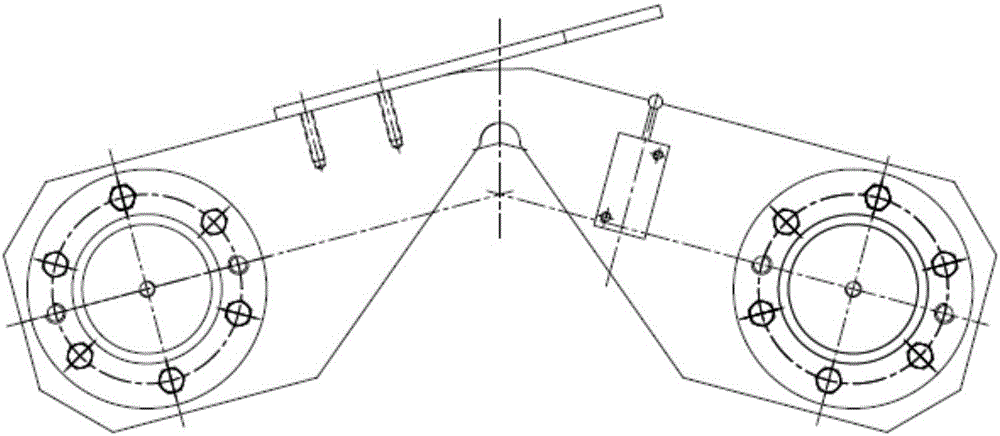

[0018] The present invention is a V-shaped safety connecting rod mechanism of the water guide mechanism of a tubular water turbine. The main components are assembling relation see figure 1 Shown: The eccentric pin 5 and the connecting rod pin 11 are respectively assembled with the ball bearing 4 using the retaining ring 12, and the two ball bearings 4 are respectively installed in the hole of the V-shaped safety connecting rod 1; the bearing plate 2 is fixed in the bolt 3 On the V-shaped safety connecting rod 1, it is used to compress the ball bearing 4; the detection plate 8 is fixed on the side of the V-shaped safety connecting rod 1 by bolts 6 and spring washers 7; the limit switch 9 is fixed on the V-shaped safety connecting rod by screws 10 1 on; the action contact of the limit switch 9 is in contact with the detection board 8.

[0019] The said V-shaped safety link mechanism transmits the operating force of the servomotor when it is working normally. When the guide vane is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com