Non-immersive liquid-level measurement sensor and installation and application method thereof

A liquid level measurement and sensor technology, which is used in measurement devices, liquid/fluid solid measurement, liquid level indicators, etc. Simple, easy to re-use, quick and easy to install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

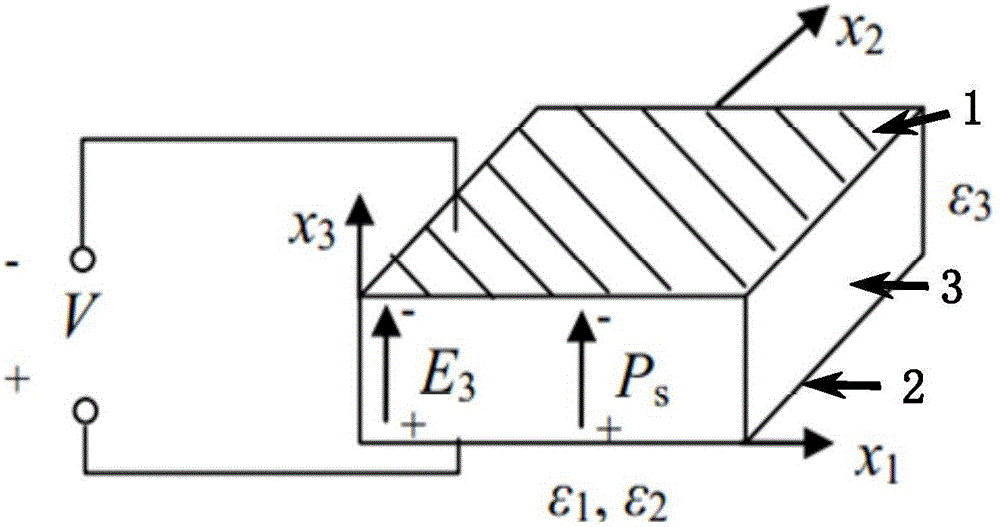

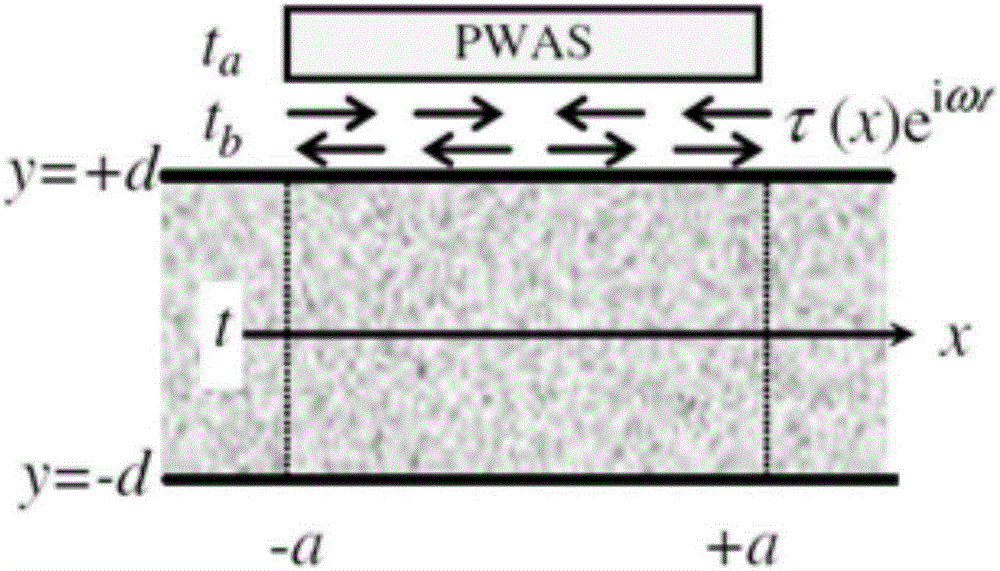

[0049] The present invention provides a non-immersed liquid level measurement sensor based on ultrasonic guided waves - thin active piezoelectric sensors (piezoelectric wafer active sensors, referred to as PWAS), such as figure 1 shown. PWAS sensors are small in size and light in weight, and are easy to integrate with the structure to be measured (pasted on the surface of the structure or embedded inside the structure). The working principle of PWAS is based on piezoelectric effect and inverse piezoelectric effect. PWAS in plane x 1 x 2 direction dimension is much larger than its plane x 1 x 3 Dimensions in direction, using piezoelectric coupling d 31 The coupling of mechanical parameters and electrical parameters is realized to realize the effective excitation and reception of ultrasonic guided waves. The coupling between the PWAS and the plate is in-plane coupling at the edge of the PWAS. When the PWAS is adhered to the surface of a thin-walled plate, the thickness of ...

Embodiment 2

[0067] The present invention provides a non-immersive liquid level measurement sensor based on ultrasonic guided waves - a thin active piezoelectric sensor (PWAS), such as figure 1 shown. The present invention will be further described with experimental cases below in conjunction with the accompanying drawings and specific implementation methods.

[0068] The PWAS described in the present invention utilizes piezoelectric coupling d 31 Realize the coupling of mechanical parameters and electrical parameters, in the plane x 1 x 2 direction dimension is much larger than its plane x 1 x 3 Dimensions in the direction to achieve effective excitation and reception of guided waves, such as figure 1 shown.

[0069] After the PWAS of the present invention sticks to the thin-walled plate surface, as figure 2 Shown, through the coupling of in-plane motion.

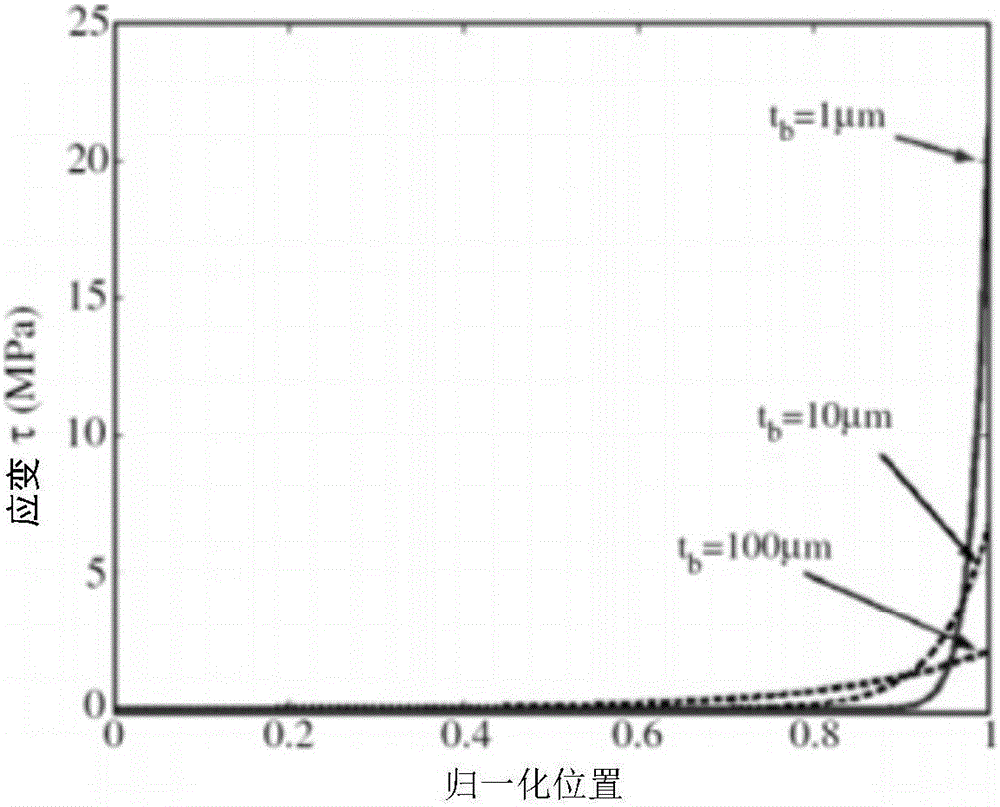

[0070] When the PWAS described in the present invention is pasted on the surface of the structure, the thickness of the adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com