Sampling device and method for wet-process lead recycling, dissolving and leaching procedures

A sampling device and lead recovery technology, applied in the field of sampling, can solve the problems of prolonging the reaction time, harming human health, affecting the reaction state in the kettle, etc., and achieving the effects of shortening the reaction time, improving the recovery efficiency and protecting human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

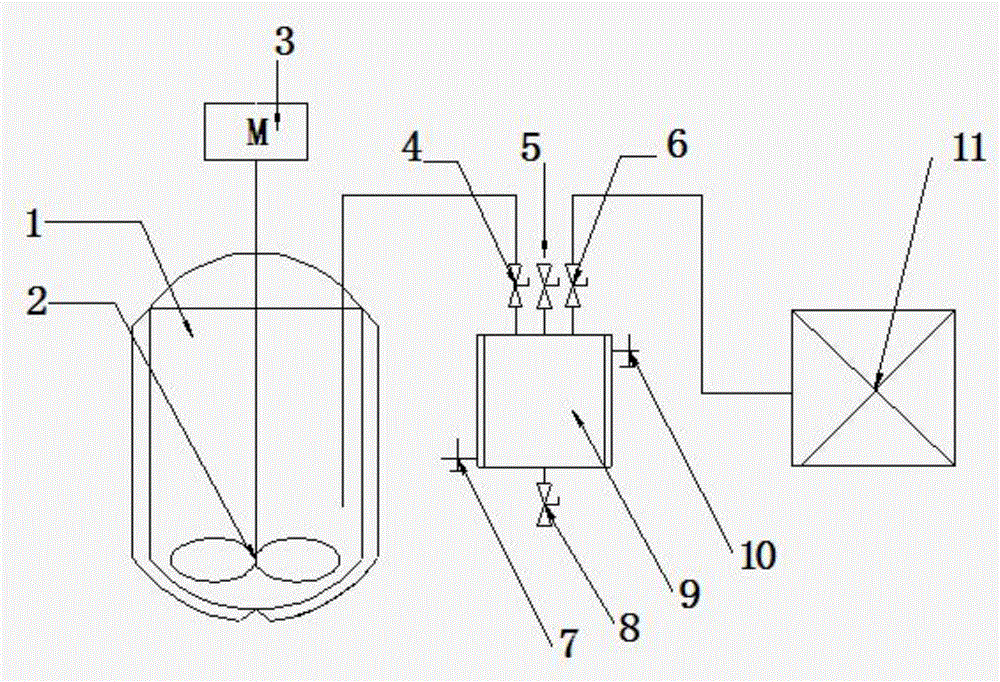

[0020] A kind of sampling method of wet-process lead recovery, dissolution and leaching process, during sampling analysis, first open the cooling water outlet valve 10 and the cooling water inlet valve 7 on the jacketed airtight glass tank 9, then close the vent valve 5, discharge valve 8, and then Turn on the water flushing pump 11 sequentially, the water flushing shut-off valve 6 and the sampling feed shut-off valve 4 start sampling, and the sampling is completed when the sample in the reactor 1 enters the jacketed airtight glass jar 9 .

[0021] After sampling, first close the water flushing pump cut-off valve 6, turn off the water flushing pump 11, and open the vent valve 5 within 1 minute. After the residual material in the sampling feed shut-off valve 4 is reversely pressed into the reactor 1, close the sampling Feed cut-off valve 4, after the material in the jacketed airtight glass tank 9 is cooled to room temperature, close the cooling water inlet valve 7 and the coolin...

Embodiment 2

[0023] A kind of sampling method of wet-process lead recovery, dissolution and leaching process, during sampling analysis, first open the cooling water outlet valve 10 and the cooling water inlet valve 7 on the jacketed airtight glass tank 9, then close the vent valve 5, discharge valve 8, and then Turn on the water flushing pump 11 sequentially, the water flushing shut-off valve 6 and the sampling feed shut-off valve 4 start sampling, and the sampling is completed when the sample in the reactor 1 enters the jacketed airtight glass jar 9 .

[0024] After sampling, first close the water flushing pump cut-off valve 6, turn off the water flushing pump 11, and open the vent valve 5 within 3 minutes. After the residual material in the sampling feed shut-off valve 4 is reversely pressed into the reactor 1, close the sampling Feed cut-off valve 4, after the material in the jacketed airtight glass tank 9 is cooled to room temperature, close the cooling water inlet valve 7 and the cooli...

Embodiment 3

[0026] A kind of sampling method of wet-process lead recovery, dissolution and leaching process, during sampling analysis, first open the cooling water outlet valve 10 and the cooling water inlet valve 7 on the jacketed airtight glass tank 9, then close the vent valve 5, discharge valve 8, and then Turn on the water flushing pump 11 sequentially, the water flushing shut-off valve 6 and the sampling feed shut-off valve 4 start sampling, and the sampling is completed when the sample in the reactor 1 enters the jacketed airtight glass jar 9 .

[0027] After sampling, first close the water flushing pump shut-off valve 6, turn off the water flushing pump 11, open the vent valve 5 within 5 minutes, and wait for the residual material in the sampling feed shut-off valve 4 to be reversely pressed into the reactor 1, then close the sampling Feed cut-off valve 4, after the material in the jacketed airtight glass tank 9 is cooled to room temperature, close the cooling water inlet valve 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com