Thermally sprayed coating contact fatigue test machine capable of realizing failure early warning

A contact fatigue, thermal spray coating technology, applied in the field of fatigue testing machine, can solve the problem of inability to detect rolling fatigue degree and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

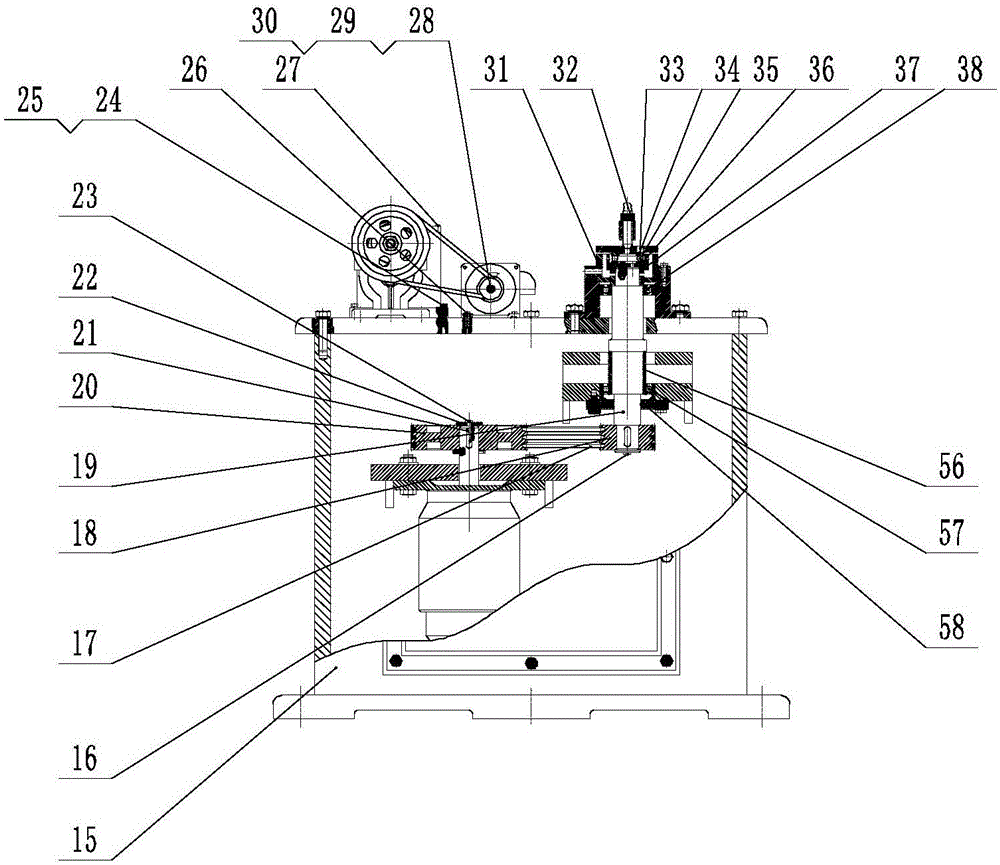

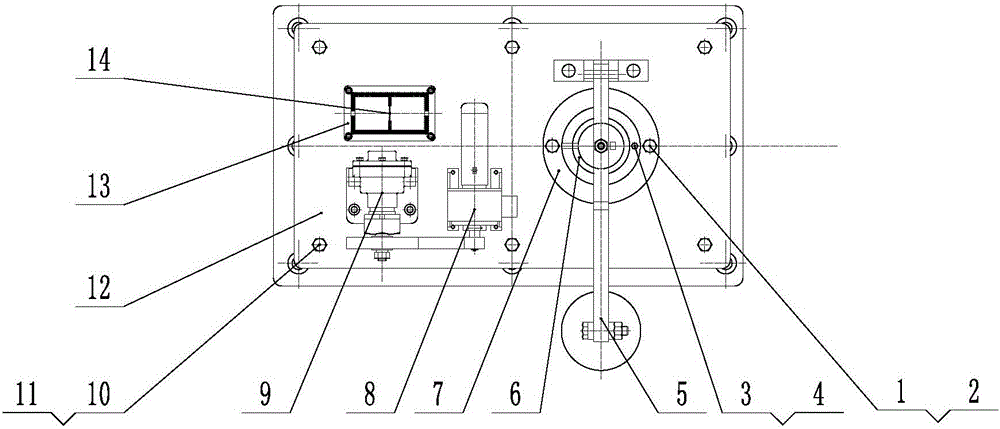

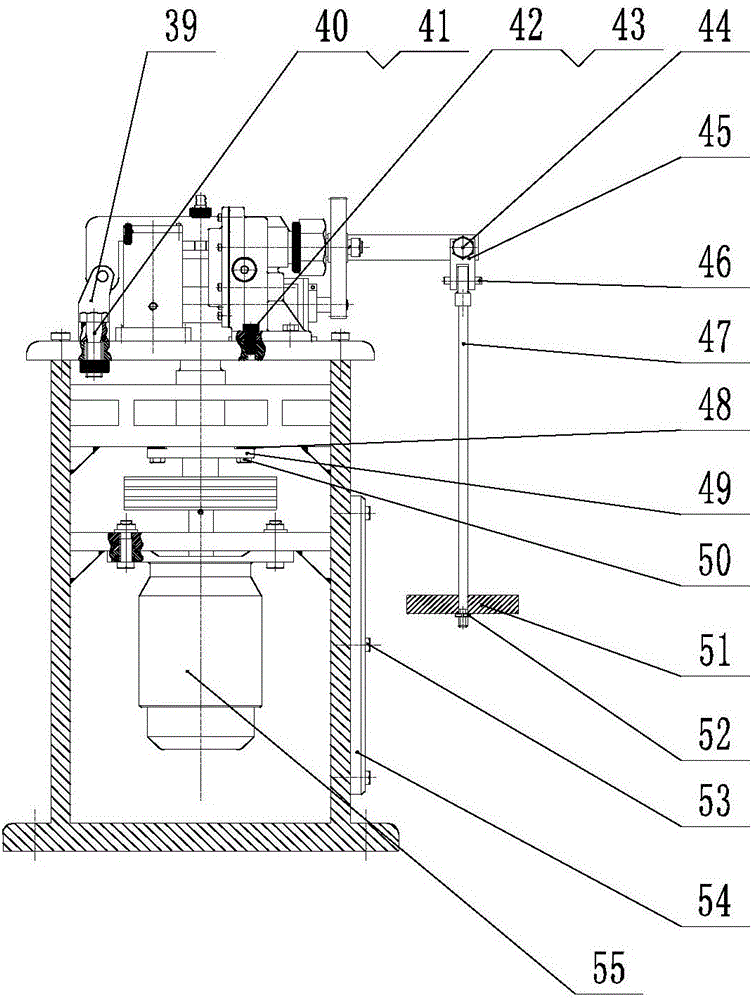

[0026] refer to Figure 1 to Figure 9 , a thermal spray coating contact fatigue testing machine capable of realizing failure early warning, including a test device, a lubrication module, a loading module, a driving module and a signal acquisition module;

[0027] Described test device comprises test chamber 37, lubricating liquid chamber 31, upper sample fixed disk 6, upper sample 34, roller 35 and lower sample 36, lubricating liquid chamber 31 is sleeved on the main shaft 19, the lower end of test chamber 37 Interference fit with the end of the main shaft 19 and fixed with the main shaft, so that the main shaft drives the test chamber to rotate circumferentially during the rotation; the lower sample 36 is assembled in the test chamber 37, and the distance between the lower sample 36 and the test chamber 37 is Interference fit: the upper sample 34 and the upper sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com