Humidity detecting system based on full-wave rectification design

A technology of humidity detection and full-wave rectification, which is applied in the field of detection, can solve the problems of inaccurate humidity sensors and different indication values, and achieve the effect of improving the running time and life of equipment and ensuring smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

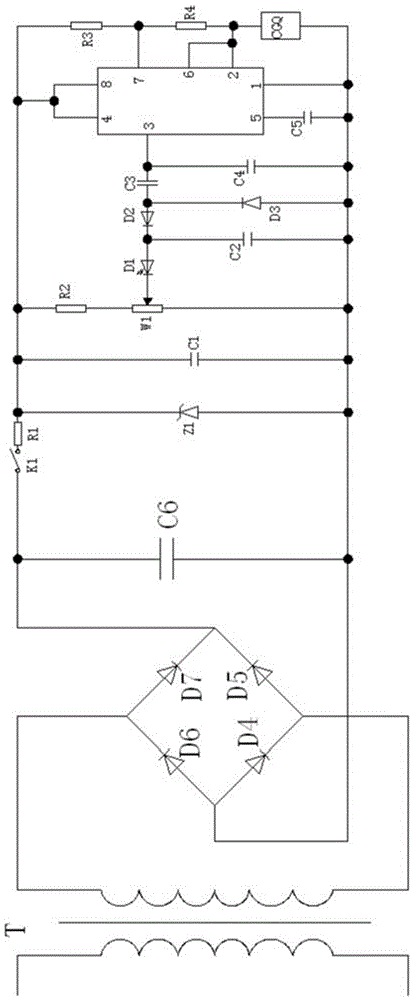

[0033] A humidity detection system based on full-wave rectification design, which uses full-wave rectification technology to rectify the AC power supply and clears the ripple voltage in the rectified DC voltage through a filter circuit to provide the required working voltage for the humidity detection processing circuit , and can use the humidity detection processing circuit to detect and process the humidity information in the environment for display, so that the user can know the humidity information at this time in time, such as figure 1As shown, the following structure is specially set up: a transformer T, a rectification circuit, a filter circuit and a humidity detection processing circuit are provided; the primary end of the transformer T is connected to a 220V AC power supply, and the secondary end of the transformer T is connected to the rectification circuit The AC input terminal of the rectifier circuit is connected in parallel with the filter circuit, and the filter ...

Embodiment 2

[0036] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as figure 1 As shown, the following arrangement structure is particularly adopted: the rectifier circuit is provided with a diode D4, a diode D5, a diode D6 and a diode D7, the anode of the diode D4 and the anode of the diode D6 are connected together and constitute one end of the DC output end, and the diode D5 and The cathode of diode D7 is connected in common and constitutes the other end of the DC output end; the cathode of diode D6 is connected in common with the anode of diode D7 and constitutes one end of the AC input end; the cathode of diode D4 is connected in common with the anode of diode D5 and constitutes the other end of the AC input end .

Embodiment 3

[0038] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 As shown, the following arrangement structure is adopted in particular: the cathode of the diode D5 is the first terminal of the DC output terminal, and the anode of the diode D4 is the second terminal of the DC output terminal; the filter circuit is provided with a filter capacitor C6, and the filter capacitor A first end of C6 is connected to the cathode of the diode D5, and a second end of the filter capacitor C6 is connected to the anode of the diode D4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com