A storage battery intelligent monitoring system

An intelligent monitoring and storage battery technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as inaccurate acquisition of battery status, complex construction environment, hidden safety hazards, etc., to avoid time waiting and inconsistency, and achieve consistency Sexuality and real-time performance, the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

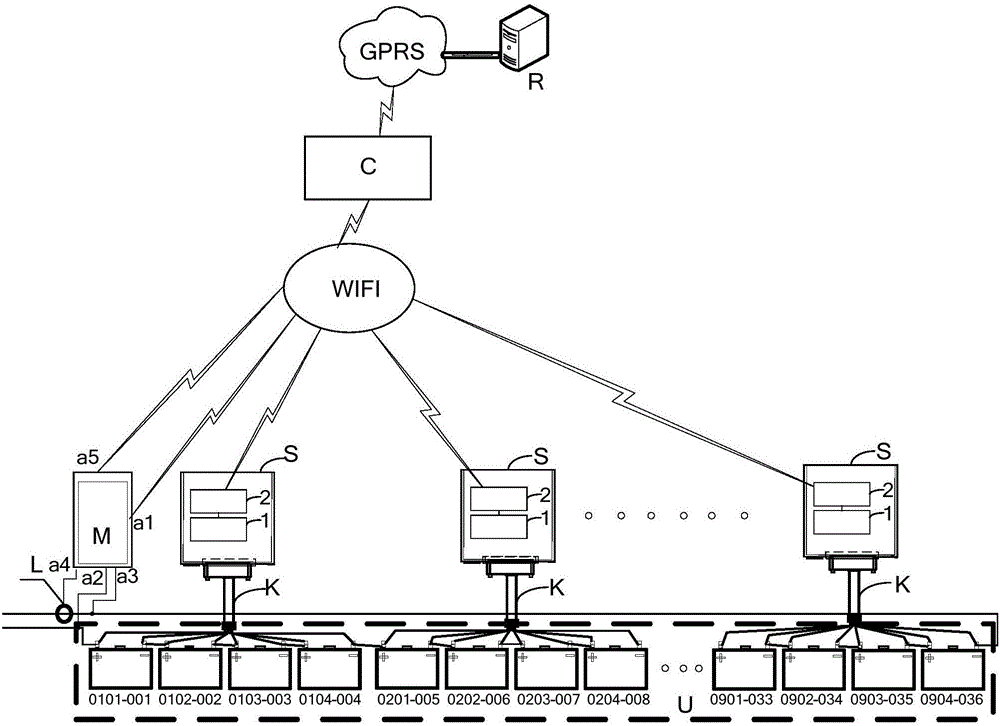

[0031] Such as figure 1 Shown is a battery intelligent monitoring system provided in an embodiment of the present invention. The battery intelligent monitoring system is matched with a plurality of battery packs each formed by a plurality of battery cells in series and / or in parallel, and has two phases. The adjacent battery packs are connected to each other to form a voltage source U to be tested; among them,

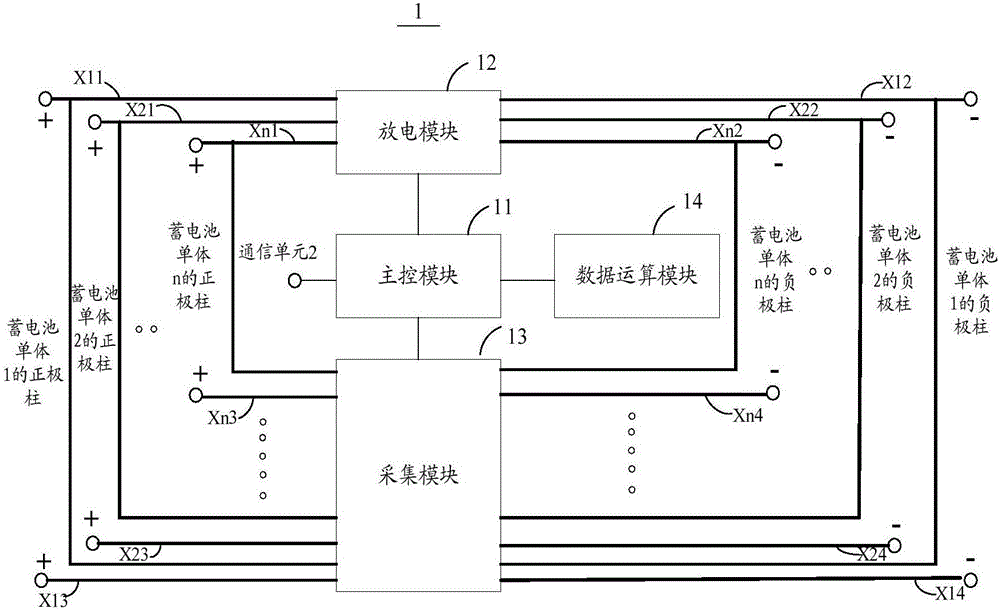

[0032] The battery intelligent monitoring system includes several battery monitoring devices S for real-time acquisition and calculation of the performance parameters of each battery cell in the corresponding battery pack, and one for real-time detection of the total voltage, total current and voltage ripple coefficient formed by the voltage source U to be te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com