Molecular-level real time optimization (RTO) method for oil refining and petrochemical device

A molecular level, petrochemical device technology, applied in the direction of comprehensive factory control, instrumentation, comprehensive factory control, etc., can solve problems such as difficult global optimization and real-time optimization, poor optimization effect, accuracy impact, etc., to achieve rapid optimization effect, Effective optimization scheme, complete effect of prediction and optimization capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

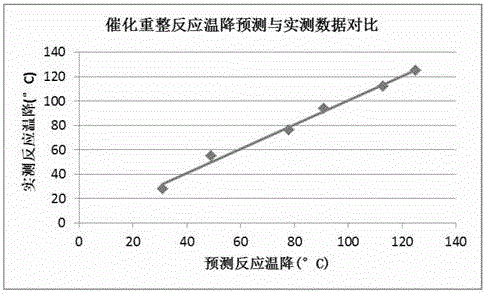

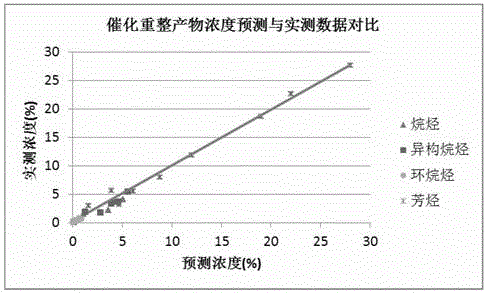

[0048] [Embodiment 1] The embodiment of the present invention applied to a catalytic reformer.

[0049] 1. Taking a catalytic reforming unit as the implementation object, using an online chromatographic analyzer as an online detection instrument to detect the macroscopic properties of raw materials and products in real time, including the content of saturated hydrocarbons, unsaturated hydrocarbons, toluene, xylene and other substances; image 3 The structural configuration of the online chromatographic analyzer used in this example is shown.

[0050] 2. According to the macroscopic properties of the raw material obtained by the online chromatographic analyzer in step 1, compare the molecular database of the reformed raw material to obtain the detailed molecular composition of the raw material. Among the molecular components of reforming raw materials, there are a total of 243 molecular components such as n-alkanes, isoparaffins, five-membered cycloalkanes, six-membered cycloal...

Embodiment 2

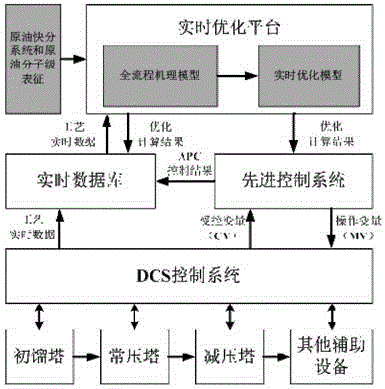

[0062] [Example 2] The present invention is applied to the embodiment on the atmospheric and vacuum distillation unit.

[0063] 1. Take a set of combined atmospheric distillation and vacuum distillation as the implementation object, and use an online near-infrared spectrum analyzer or nuclear magnetic resonance analyzer as an online detection instrument to detect the properties of raw materials and products in real time. Detection objects include crude oil, constant top oil, constant first line, constant second line, constant third line, minus first line, minus second line, minus third line, minus four line and other streams. The detection properties include density, distillation range, dry point, viscosity, carbon residue, sulfur content, etc.

[0064] 2. According to the crude oil properties obtained by the online near-infrared spectrometer or nuclear magnetic resonance analyzer in step 1, compare the crude oil molecular database to obtain the detailed molecular composition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com