High-molecular composition used for plastic building template and its preparation method

A building template and polymer technology, applied in the field of building materials, can solve the problems of low strength, poor impact resistance, easy to break, etc., and achieve the effects of high strength, good impact resistance and low comprehensive cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

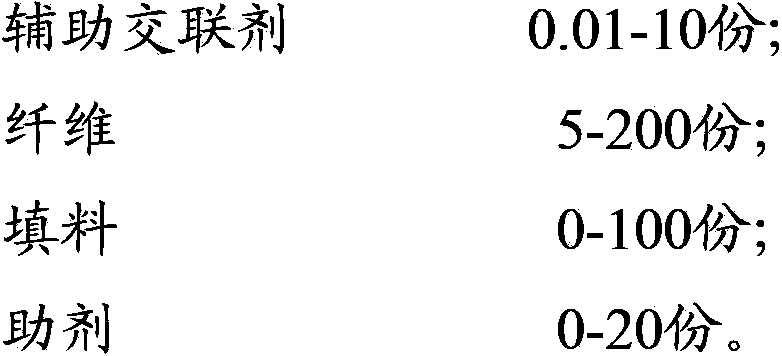

Method used

Image

Examples

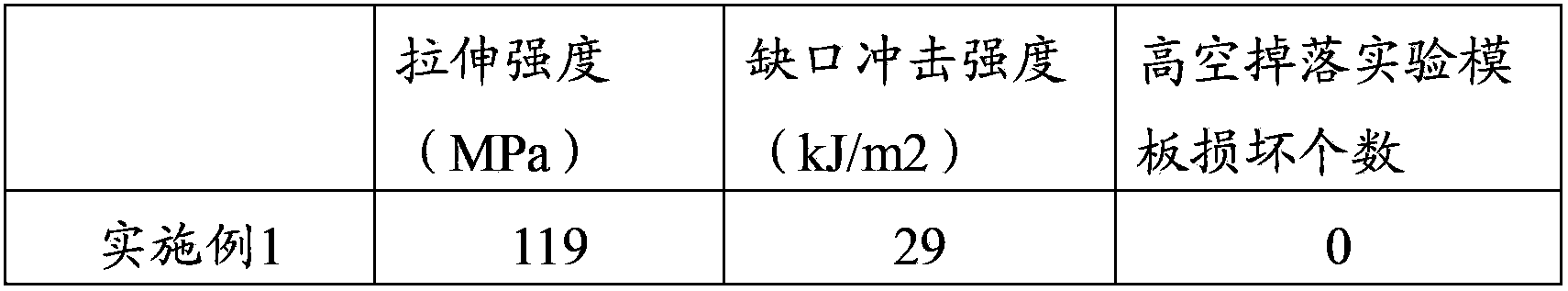

Embodiment 1

[0031] Put 100 parts of polypropylene regrind, 0.01 part of dicumyl peroxide and 0.01 part of N,N'-ethylene bismaleimide into a high mixer at room temperature and mix evenly; then mix the mixed materials, Add from the hopper of the extruder, add 80 parts of glass fiber from the fiber inlet, melt and extrude through the extruder, cool, dry, and pelletize to obtain a polymer composition for plastic building templates. The heating temperature range of the extruder is 150°C in the feeding section, 230°C in the melting section, and 230°C in the homogenizing section.

Embodiment 2

[0033] 100 parts of polyethylene recycling, 0.1 parts of di-tert-butyl peroxide, 0.2 parts of N,N'-p-phenylene bismaleimide, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, Put 10 parts of paraffin wax, 20 parts of talc powder and 0.5 parts of coupling agent γ-aminopropyltriethoxysilane into the high mixer at room temperature and mix evenly; then add the mixed material from the hopper of the extruder, 60 parts of glass fibers are added from the fiber inlet, melted and extruded through an extruder, cooled, dried, and pelletized to obtain a polymer composition for plastic building templates. The heating temperature range of the extruder is 120°C in the feeding section, 190°C in the melting section, and 190°C in the homogenizing section.

Embodiment 3

[0035] 100 parts of polypropylene recycling, 0.5 parts of dicumyl peroxide, 2 parts of N,N'-p-phenylene bismaleimide, 100 parts of glass beads, 0.5 parts of antioxidant 1098, 0.5 parts Antioxidant 168, 2 parts of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate and 17 parts of stearic acid were put into a high mixer and mixed evenly at room temperature; then the mixed material was extruded 20 parts of glass fibers are added from the fiber inlet, melted and extruded by an extruder, cooled, dried, and pelletized to obtain a polymer composition for plastic building formwork. The heating temperature range of the extruder is 140°C in the feeding section, 230°C in the melting section, and 230°C in the homogenizing section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com