Torsional vibration prediction and elimination method for drive system of hybrid power bus

A hybrid power and transmission system technology, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, special data processing applications, etc., can solve the problems of large differences in simulation analysis and estimation results, inability to be used as analysis results, and high modeling technology requirements. Achieve the effect of short calculation time, low technical threshold and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

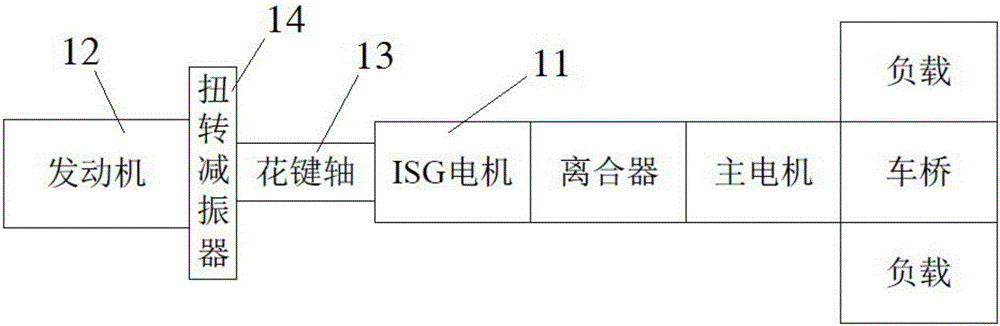

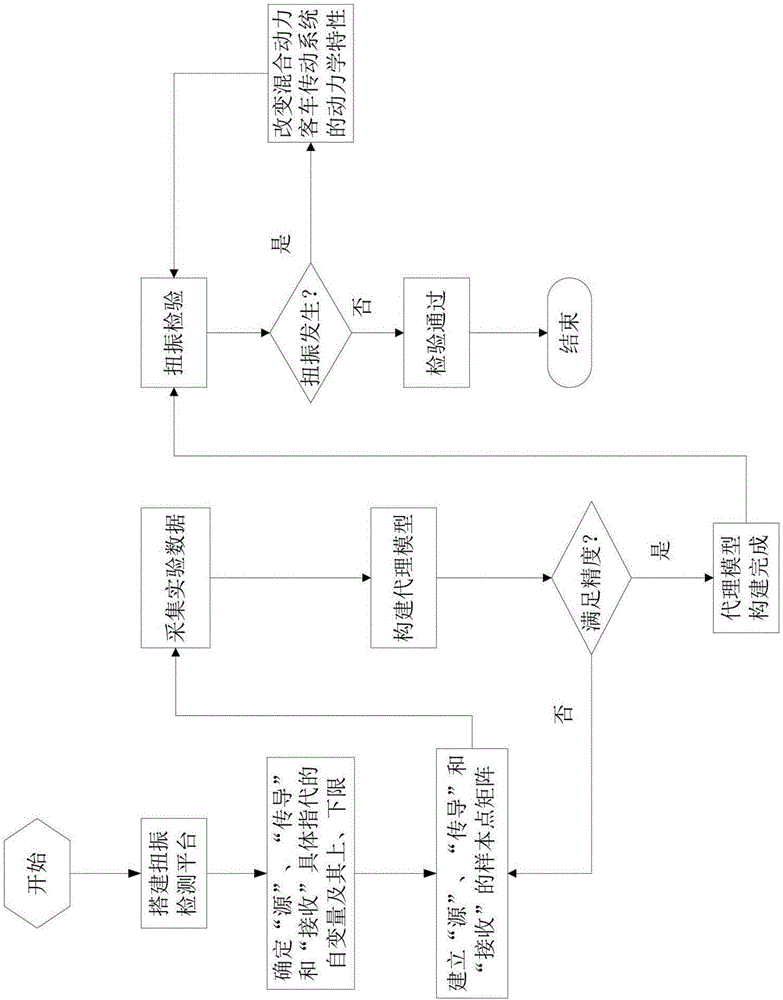

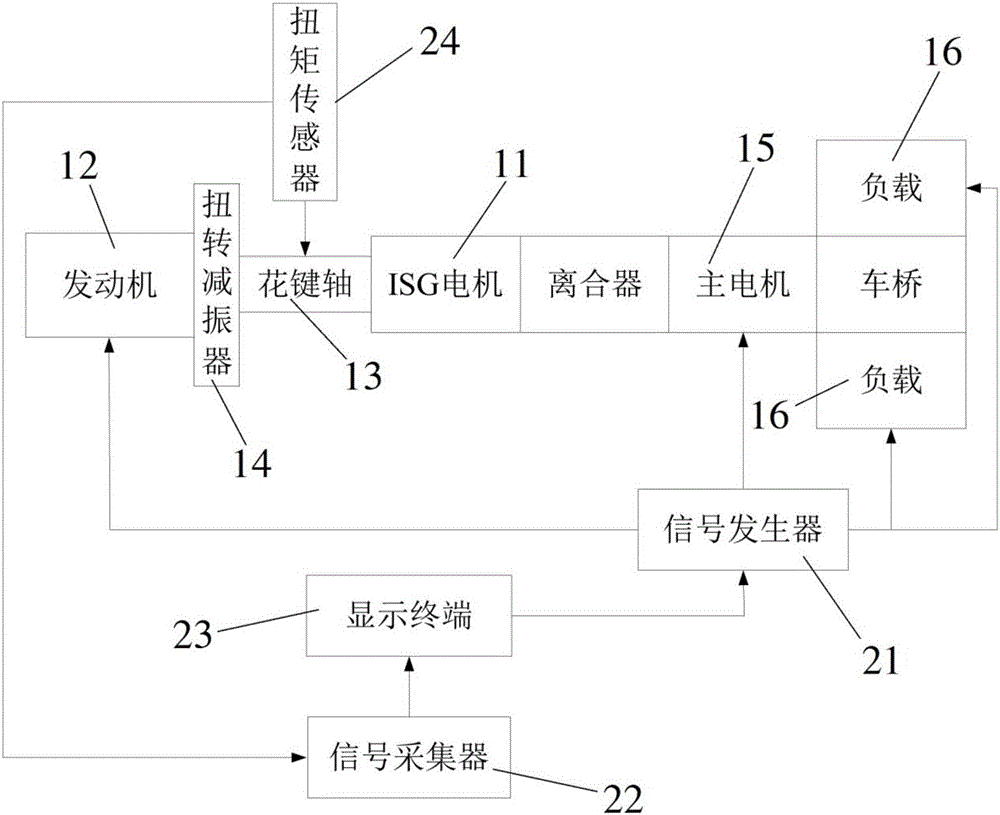

[0042] Below, combine figure 2 with 3 The method for predicting and eliminating the torsional vibration of the transmission system of the hybrid electric vehicle of the present invention is described in detail.

[0043] Such as figure 2 As shown, first, a torsional vibration detection platform is built, and the torsional vibration detection platform is connected to the transmission system of the hybrid electric bus used in the experiment. Then, determine the "source", "transmission" and "reception" in the transmission system of the hybrid electric bus used in the experiment, and take the modifiable parameters of "source", "transmission" and "reception" as independent variables, according to the collected data Determine the upper and lower bounds of the independent variable. Then, the independent variables of "source", "transmission" and "reception" are collected from the design space of the experimental hybrid electric bus transmission system as sample points, and a sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com