Display substrate, manufacturing method thereof, and display device

A technology for displaying substrates and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc. It can solve problems such as strength reduction, brittleness and hardening, and easy falling off, so as to prevent water vapor from contacting the metal layer, high hardness and Effects of aging resistance, reliability and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] form the drain on the substrate,

[0054] forming an insulating layer pattern including via holes on the drain;

[0055] A pixel electrode pattern is formed on the insulating layer pattern, and the pixel electrode pattern is connected to the drain of the display substrate through the via hole.

[0056] A water-absorbing thermosetting resin layer covering at least a part of the pixel electrode pattern is formed.

[0057] Specifically, the acrylic resin containing hydroxyl groups can be coated on the surface of the display substrate on which the pixel electrode pattern is formed, and after curing, it is etched to 600 nm, so that the surface of the display substrate is completely covered with the polyacrylic resin layer.

[0058] The processed display substrate is used in a display device, and it is continuously lit and operated for 240 hours in an environment of 60°C and 90% relative humidity. During the test, there is no abnormality in the screen display, and the produc...

Embodiment 2

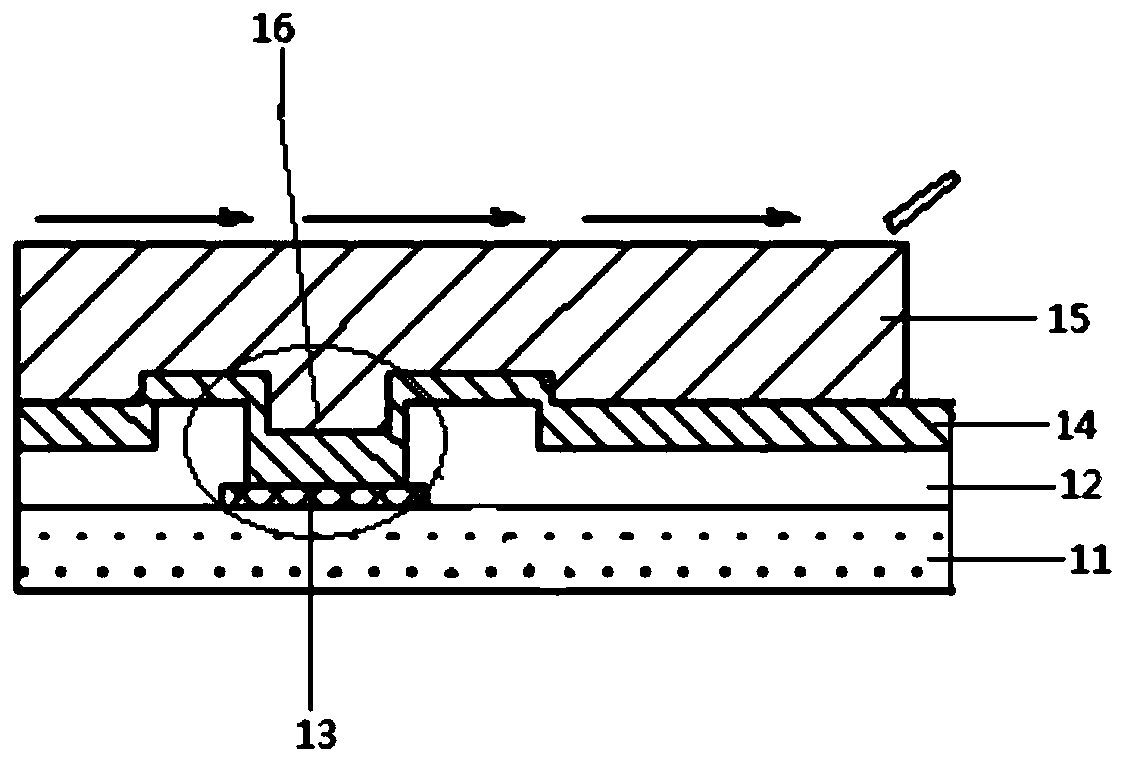

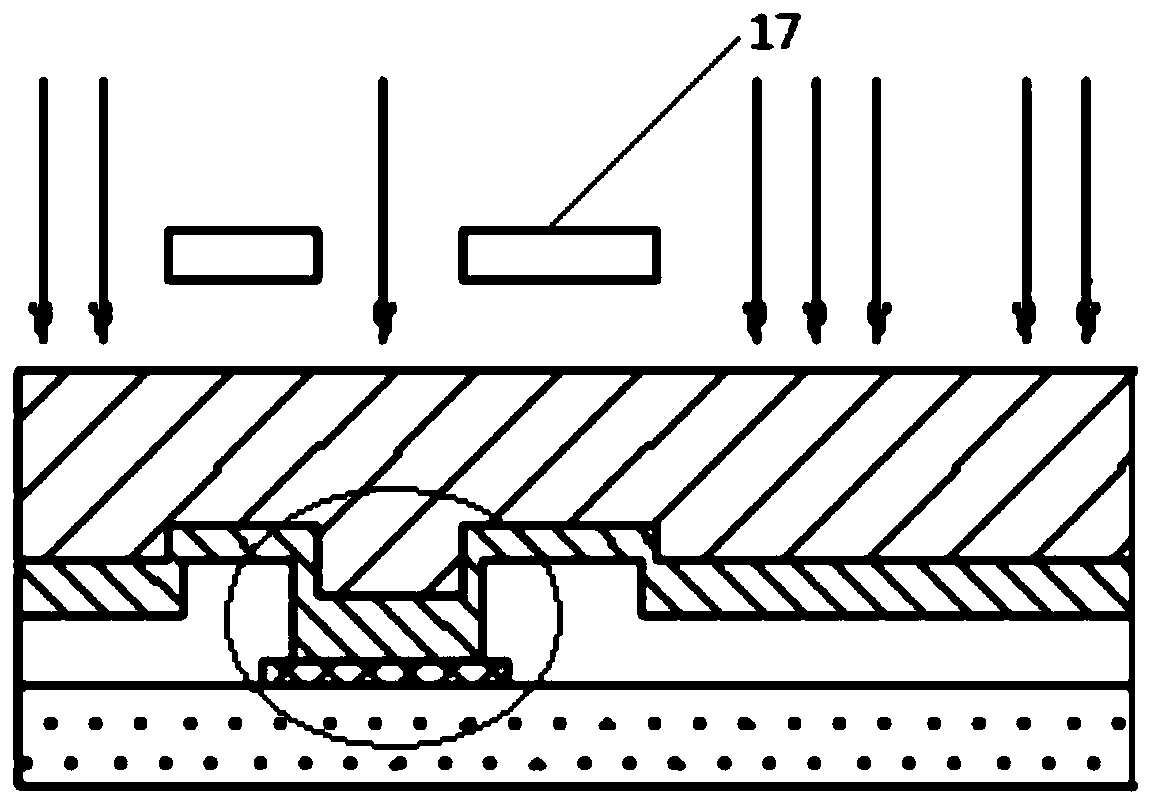

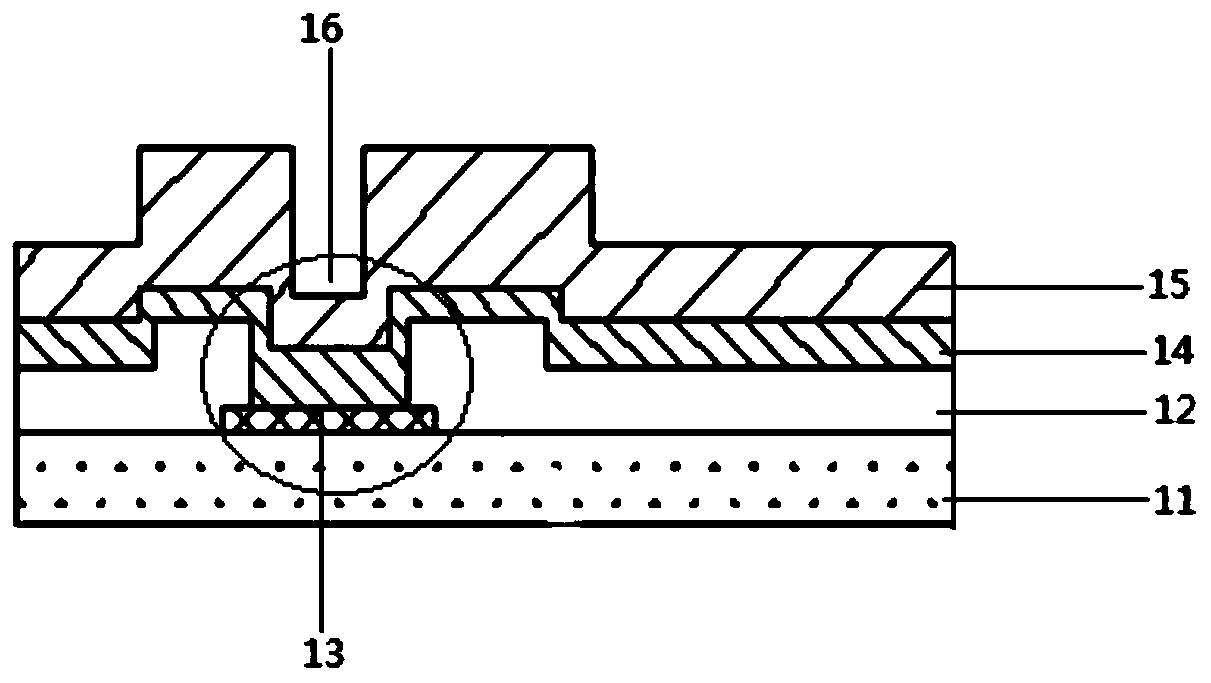

[0060] like Figure 4 As shown, the pattern of the first electrode 21 is formed on the substrate 10 through a patterning process.

[0061] A metal layer 22 is formed on the surface of the substrate on which the pattern of the first electrode 21 is formed; the metal layer 22 is electrically connected to the pattern of the first electrode 21 .

[0062] The insulating layer 12 is formed on the surface of the substrate on which the metal layer 22 is formed.

[0063] Via holes 16 are formed on the surface of the insulating layer 12 through a patterning process.

[0064] The pattern of the second electrode 23 is formed on the insulating layer pattern on which the via hole 16 is formed by a patterning process. Wherein, the second electrode 23 is electrically connected to the metal layer 22 through the via hole 16 .

[0065] Coating the acrylic resin containing hydroxyl groups on the surface of the display substrate on which the second electrode pattern is formed, and after curing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com