A kind of preparation method of graphene/gallium arsenide solar cell

A technology of solar cells and gallium arsenide, applied in the field of solar energy, can solve the problems of increasing the photo-generated carrier recombination center, improving the photoelectric conversion efficiency of gallium arsenide solar cells, large series resistance and recombination current, etc., so as to improve the photoelectric conversion efficiency. , reduce shading loss, improve the effect of filling factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

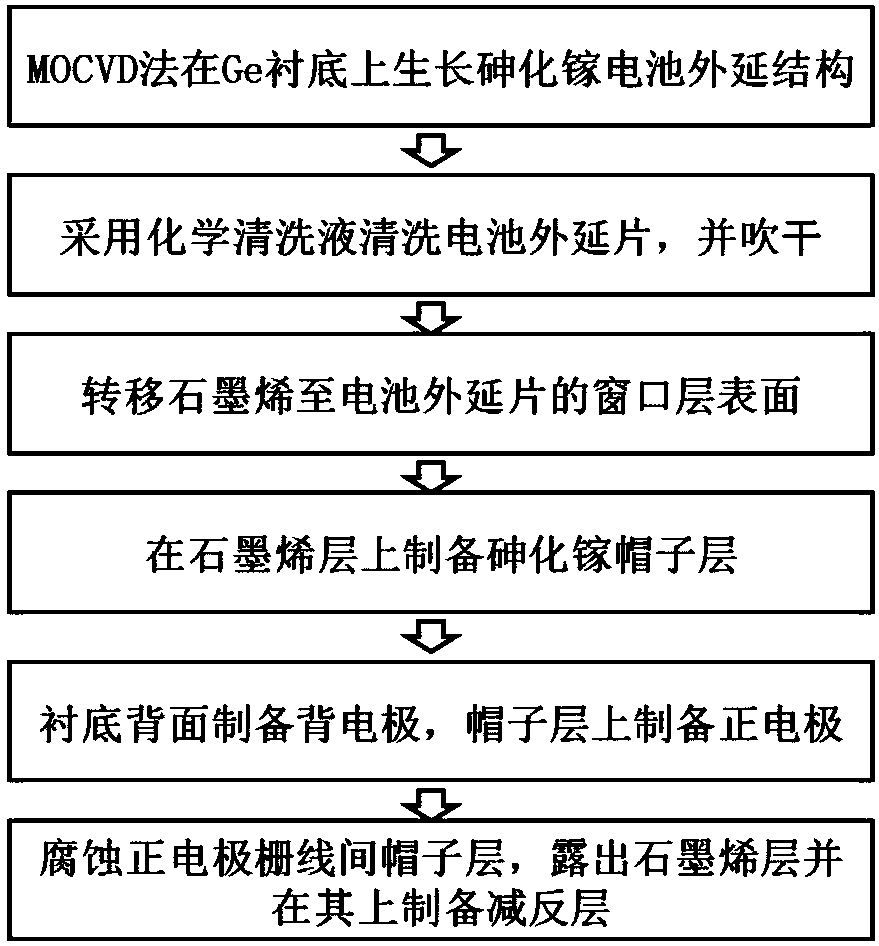

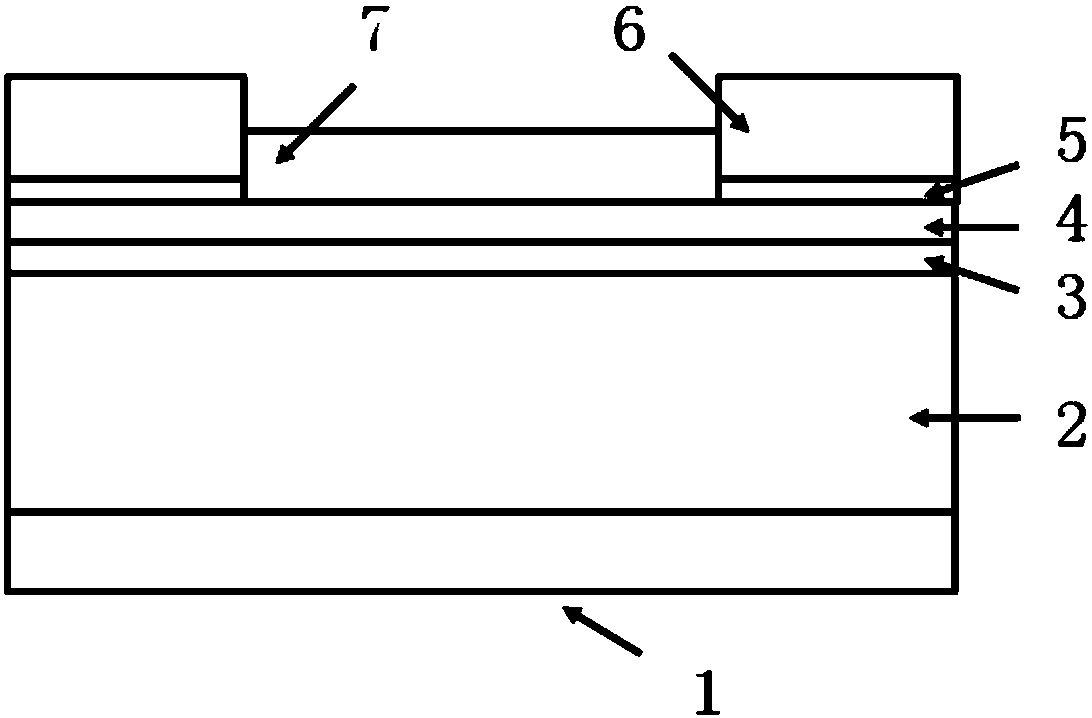

[0024] The invention provides a method for preparing a graphene / gallium arsenide solar cell, comprising the following steps:

[0025] 1) transfer the graphene to the surface of the window layer on the surface of the gallium arsenide epitaxial wafer to form a graphene layer;

[0026] 2) Prepare a heavily doped gallium arsenide cap layer on the surface of the graphene layer;

[0027] 3) preparing a back electrode on the surface of the gallium arsenide epitaxial wafer substrate, and preparing a front electrode on the surface of the heavily doped gallium arsenide cap layer;

[0028] 4) The heavily doped gallium arsenide cap layer between the front electrode grid lines is etched by chemical etching to expose the graphene layer, and an anti-reflection layer is prepared on the surface of the exposed graphene layer.

[0029] In some specific embodiments of the present invention, a cleaning step is also included before step 1). Specifically, the gallium arsenide epitaxial wafer is pla...

Embodiment 1

[0073] 1) Place the single-junction GaAs cell epitaxial wafer with the structure of GaAs / GaAs in acetone, isopropanol, and absolute ethanol, respectively, and heat it in a 60°C water bath for 15 minutes, then rinse with deionized water for 10 minutes, and then place in HCl:H 2 Soak in the solution of O=1:10 at room temperature for 1min, finally wash with deionized water and blow dry with nitrogen;

[0074] 2) transfer the monolayer graphene to the window layer on the surface of the epitaxial wafer by electrochemical method;

[0075] 3) Depositing a heavily doped gallium arsenide cap layer on the graphene layer by MOCVD;

[0076] 4) Prepare the positive electrode pattern on the surface of the heavily doped gallium arsenide cap layer by photolithography technology, and prepare the alloy back electrode and positive electrode of nickel, germanium and gold by electron beam evaporation method, remove the photoresist and alloy, and then The epitaxial wafer placed in NH 3 ·H 2 O:H...

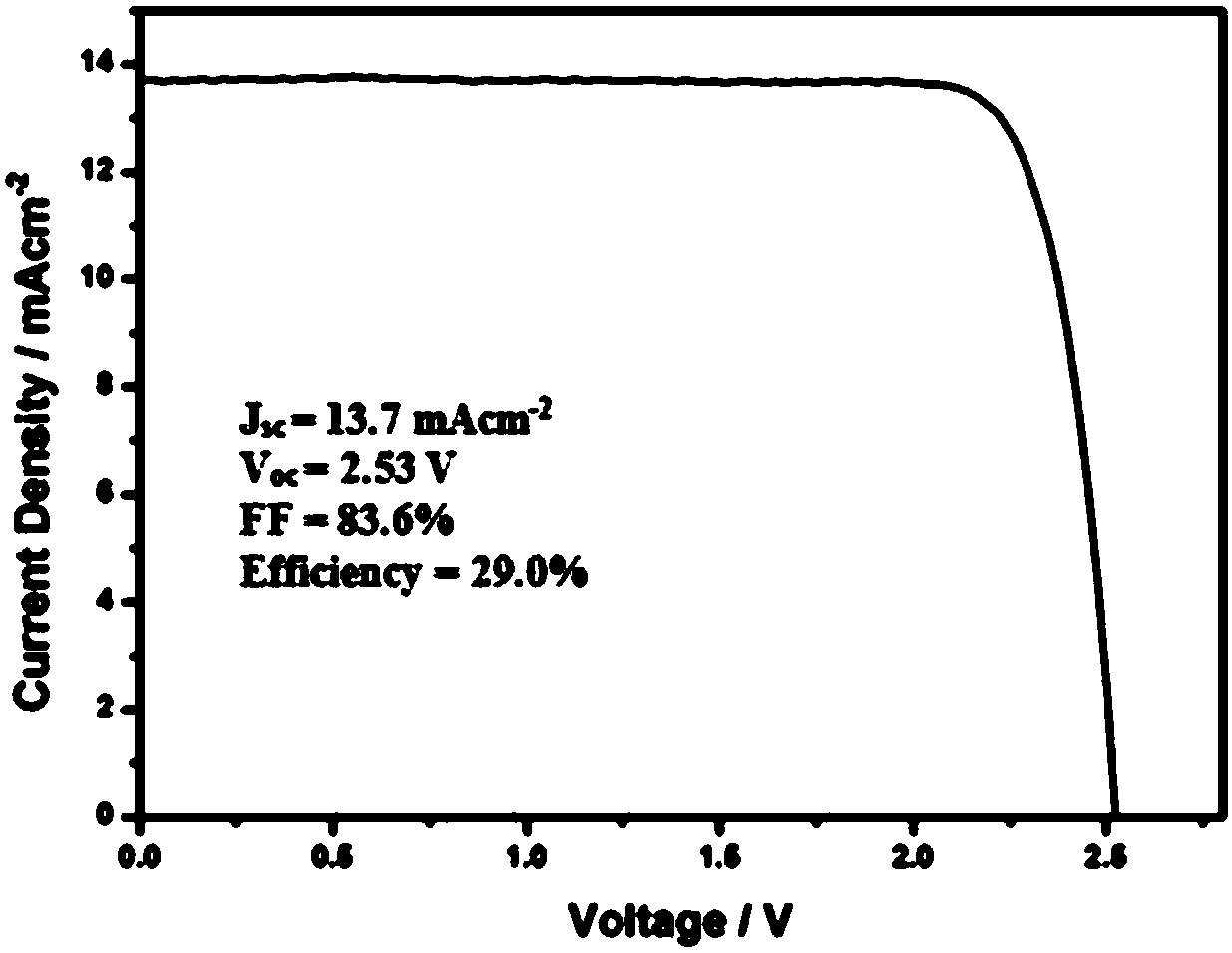

Embodiment 2

[0085] 1) Place a single-junction GaAs cell epitaxial wafer with a structure of GaAs / Ge in acetone, isopropanol, and absolute ethanol at 50°C for 20 minutes, rinse with deionized water for 10 minutes, and then place in H 2 SO 4 :H 2 o 2 :H 2 Soak in the solution of O=1:8:500 at room temperature for 3min, finally wash with deionized water and blow dry with nitrogen;

[0086] 2) transfer three layers of graphene to the window layer on the surface of the epitaxial wafer by electrochemical method;

[0087] 3) Depositing a heavily doped gallium arsenide cap layer on the graphene layer by MOCVD;

[0088] 4) Prepare the positive electrode pattern on the surface of the heavily doped gallium arsenide cap layer by photolithography, and prepare the alloy back electrode and positive electrode of nickel, germanium, silver, and gold by electron beam evaporation, remove the photoresist and alloy, Then place the epitaxial wafer in C 6 h 8 o 7 :H 2 o 2 :H 2 Erosion 20s in the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com