Cloud-aided intelligent warehouse management robot system and method

A robot system and robot technology, applied in transmission systems, digital transmission systems, instruments, etc., can solve the problems of poor task complexity expansion, useless power, poor human-computer interaction, etc., to optimize network service quality, reduce coupling, and maintain good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

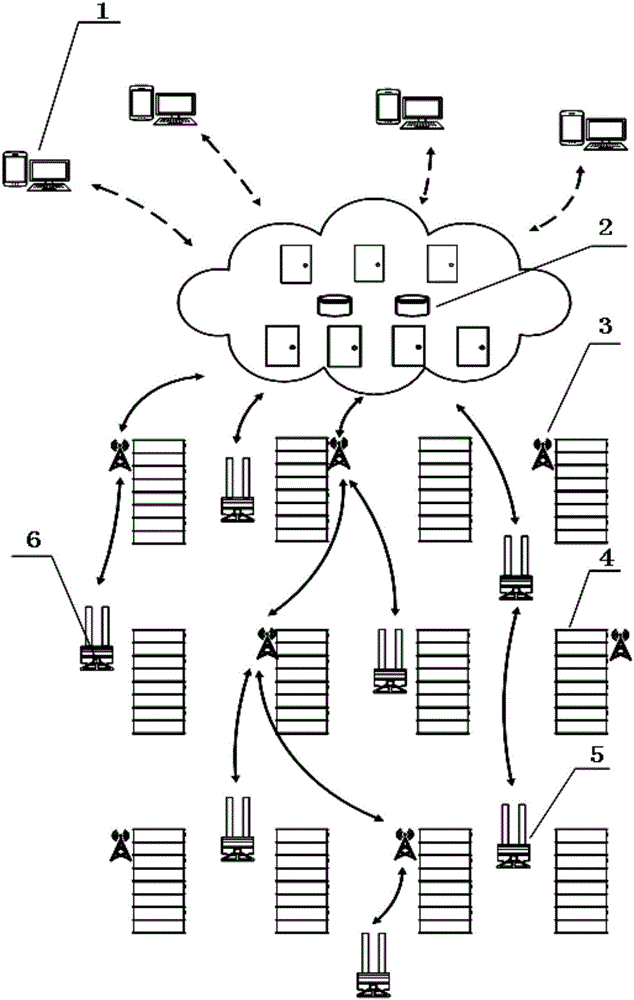

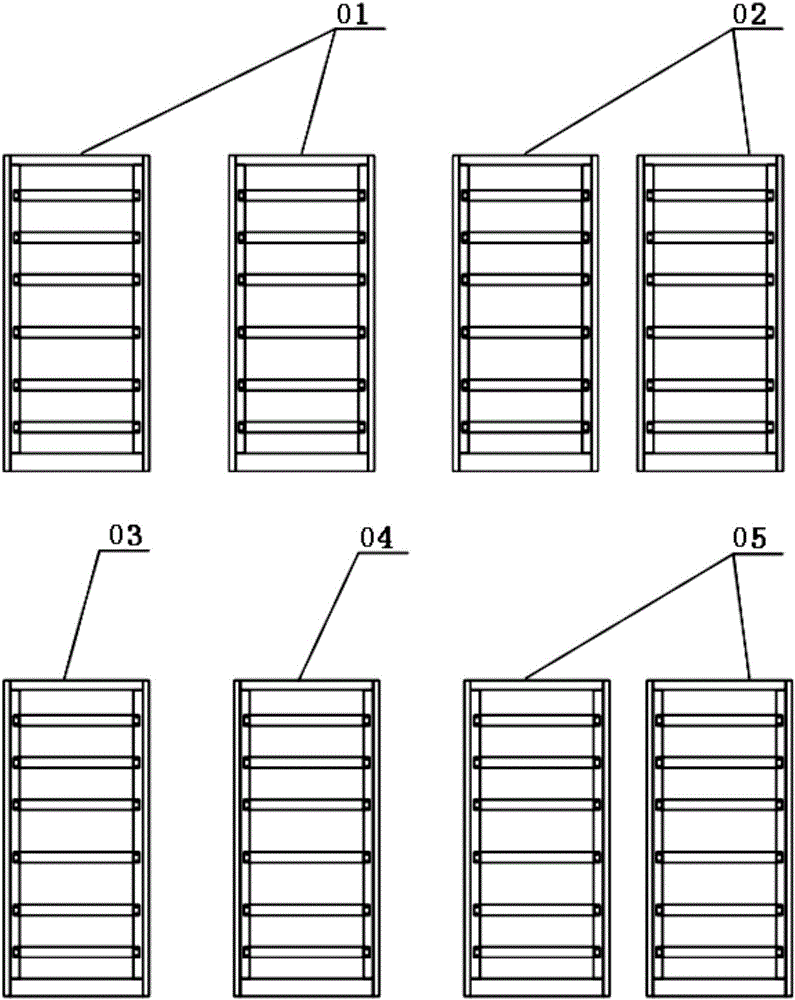

[0053] Combine below Figures 1 to 4 The present invention is described in further detail with specific embodiments.

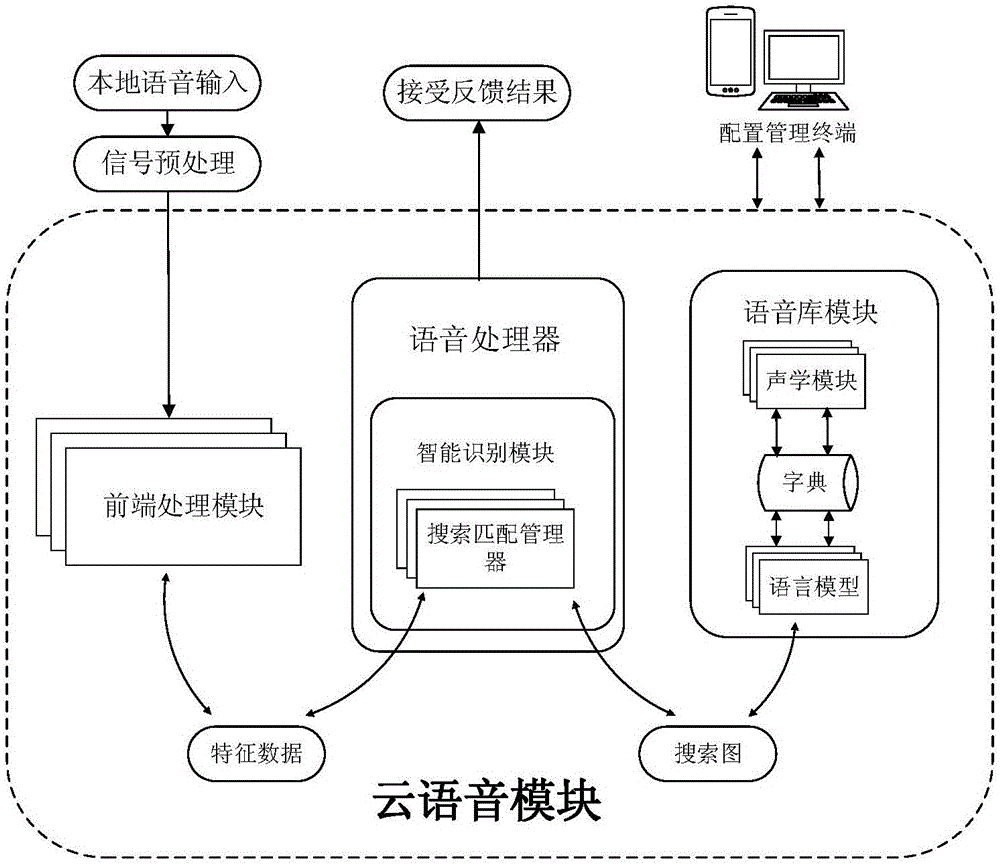

[0054] The cloud of the warehouse management robot system of the present invention is composed of multiple cloud computing server clusters, including a robot interaction module, a data storage module, a crowdsourcing module, a warehouse shelf monitoring module, and a warehouse environment monitoring module.

[0055] The robot interaction module is mainly used to interact with the underlying storage robot. Since the storage task involves multiple steps such as path planning, environment perception, and multi-operation collaborative operation, the calculation complexity is large. The storage robot of the present invention delivers these calculation tasks to the robot interaction in the cloud. Module processing. Through cloud computing technology, the robot interaction module can quickly respond to robot task requirements, issue implementation instructions in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com