A closed liquid nitrogen self-circulation rapid cooling system

A rapid cooling and self-circulation technology, applied in induction heating, coil devices, etc., can solve the problems of shortening the service life of the electromagnetic wire, breaking the electromagnetic wire, and weakening the strength of the electromagnetic wire itself, so as to prevent the rupture, improve the use efficiency, and improve the The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment: a closed liquid nitrogen self-circulation rapid cooling system.

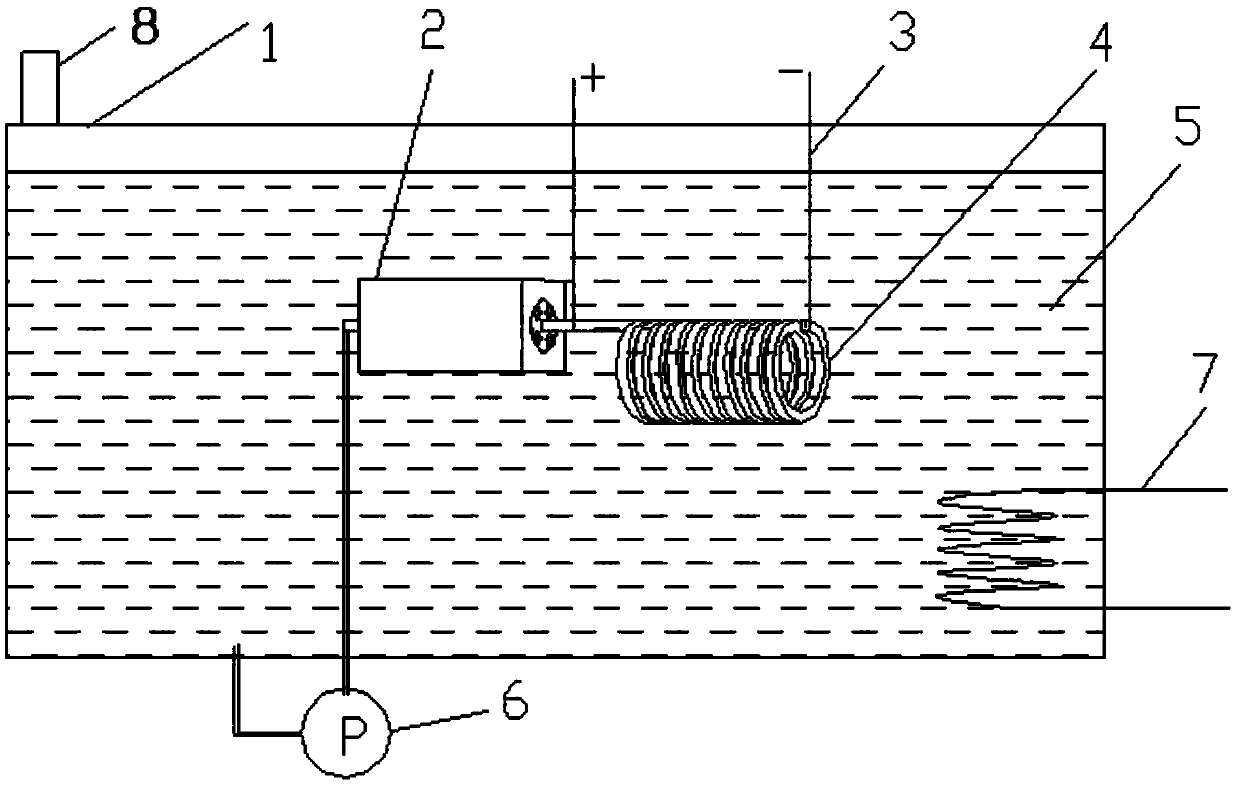

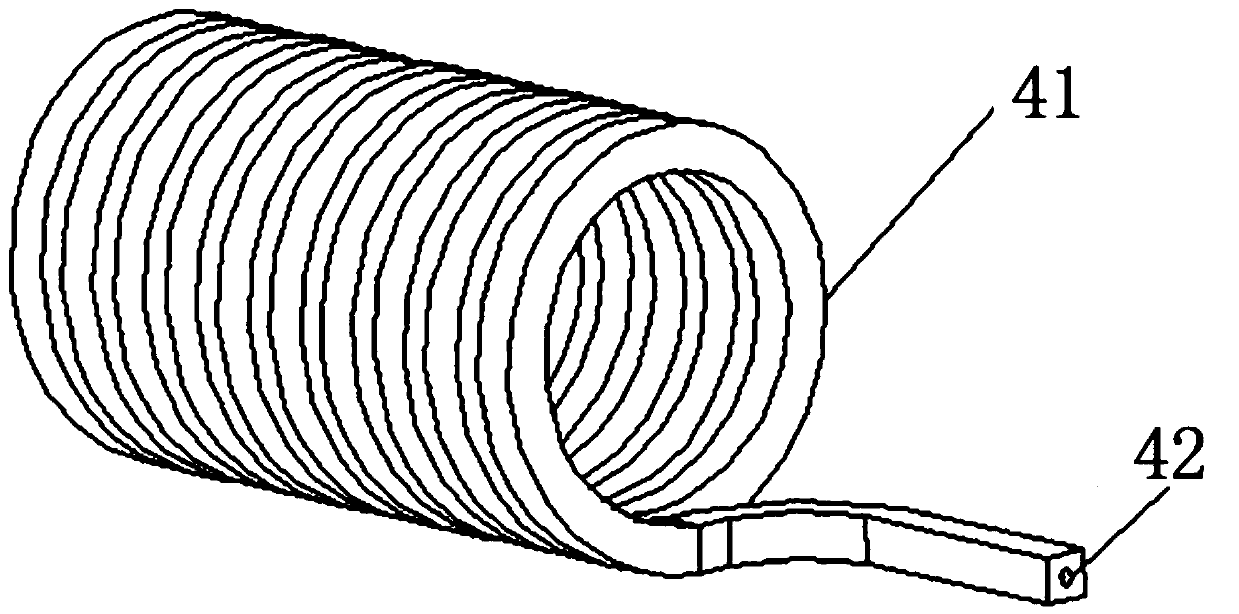

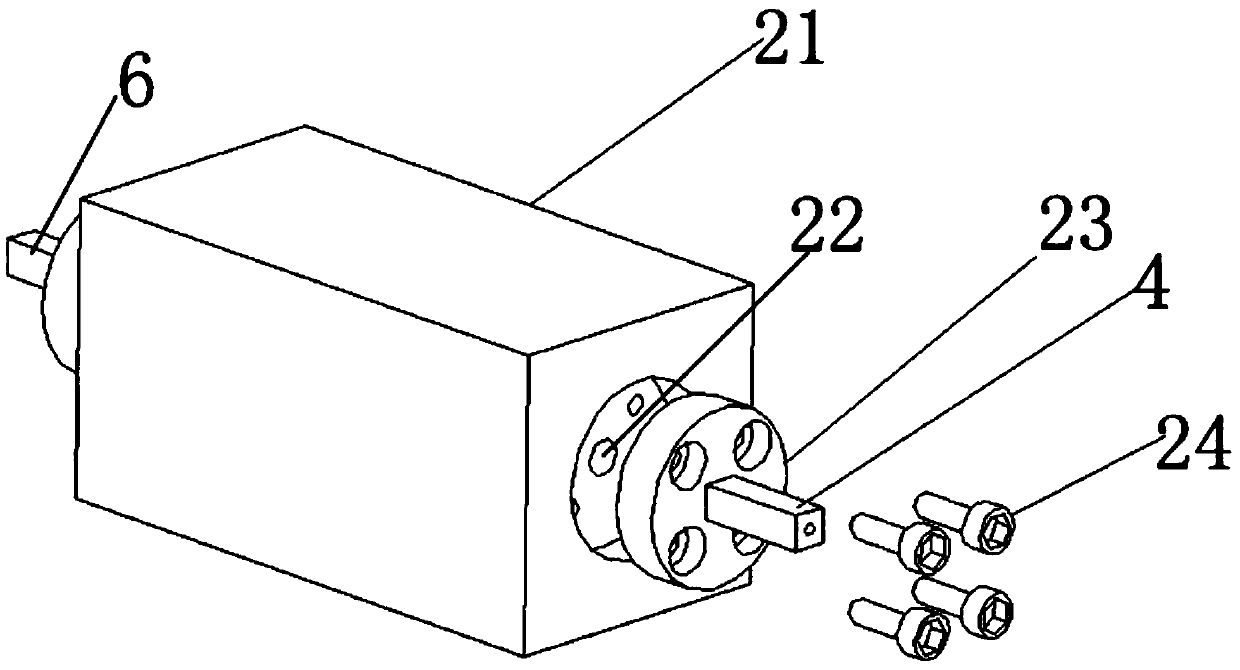

[0023] refer to figure 1 , figure 2 and image 3As shown, a closed liquid nitrogen self-circulation rapid cooling system includes: a liquid nitrogen tank 1, the liquid nitrogen tank 1 is a sealed liquid nitrogen tank, and the liquid nitrogen tank 1 is filled with liquid nitrogen 5; the lower liquid nitrogen tank 1 is installed The pressure relief valve 8 on the top, the pressure relief valve 8 is used to maintain the pressure in the liquid nitrogen tank 1 is always constant at an atmospheric pressure; the external cooling device 7 installed on the liquid nitrogen tank 1, the external cooling device 7 can be extremely fast freezing machine, the effect of the external cooling device 7 is to cool the liquid nitrogen 5 that has been increased in temperature after heat exchange to 65K; the liquid nitrogen pump 6 installed in the liquid nitrogen tank 1 or outside the liquid nitrogen tank 1; insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com