Clamping device for circuit board processing

A clamping device and circuit board technology, applied in printed circuits, printed circuit manufacturing, PCB positioning during processing, etc., can solve problems such as damage to electronic components of the circuit board, inability to operate the circuit board, and inconvenient operation, to ensure stability. performance, improved accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

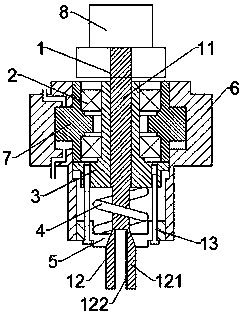

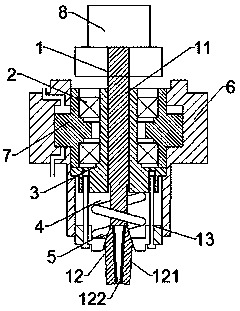

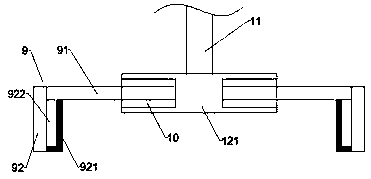

[0018] Such as Figure 1-3 As shown, a circuit board processing and clamping device is installed at the end of the mechanical arm for clamping the circuit board, including a chuck 1, a bearing 2, a push sleeve 3, a spring 4, a locking plate 5, and a first cylinder 6 And the piston 7 arranged in the first cylinder 6, the chuck 1 includes a solid rotating rod 11 at the upper end and a clamping part 12 connected to the lower end of the rotating rod 11 and composed of two clamping plates 121, the clamping plates 121 are parallel to each other Set, each clamping plate 121 can be elastically deformed along the relative direction, and the outer side of the end connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com