Liquid oral composition and method for improving freeze recovery thereof

A composition and recovery technology, used in oral care, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as emulsification damage, no mention of freezing recovery, and achieve inhibition of irritation, excellent freezing recovery, high The effect of bactericidal power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A known method can be used for the preparation method of the emulsion.

[0057] For example, after mixing a specified amount of nonionic surfactant, polyol as a dispersant, and half an amount of water with a homogeneous mixer, add an oily component to form an emulsion, and finally add the remaining water to prepare O / W type emulsion. Thereafter, the prepared emulsion can be adjusted in average particle size using a high-pressure homogenizer.

[0058] In emulsification using a high-pressure homogenizer, the average particle size can be adjusted according to the difference in shear force. When the emulsified particles are micronized, the temporal stability is further improved. As the high-pressure homogenizer, a microfluidizer (manufactured by Microfluidic Technology International Co., Ltd. (Microfluidic Technology International Co., Ltd.)), a Gaulin homogenizer (manufactured by Rannie Gaulin), an ultimaizer (manufactured by Sugino Machinery Co., Ltd.) and the like can ...

Embodiment 1~18

[0100] [Examples 1-18, Comparative Examples 1-10]

[0101] The liquid oral compositions (mouthwashes) shown in Tables 1 to 4 were prepared by conventional methods, and the appearance stability (freeze recovery) during freezing and thawing, the refreshing feeling after use in the oral cavity, and the Is there any irritation. Moreover, about the liquid oral cavity composition which mixed isopropylmethylphenol shown in Table 3, 4, biofilm bactericidal ability was further evaluated by the following method. The results are collectively described in Tables 1-4.

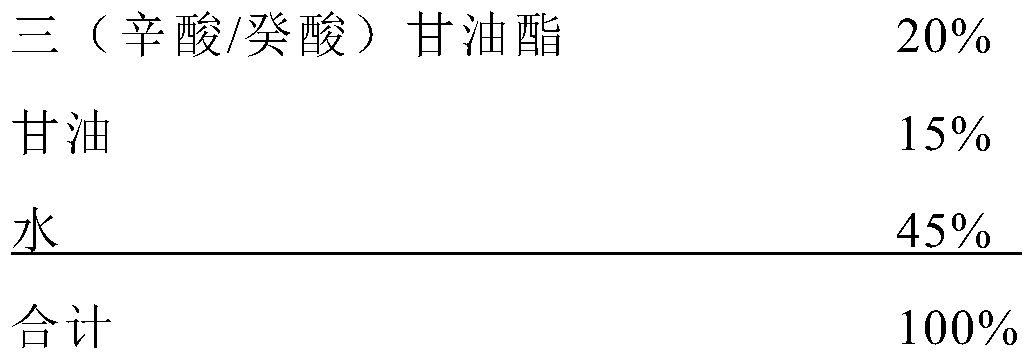

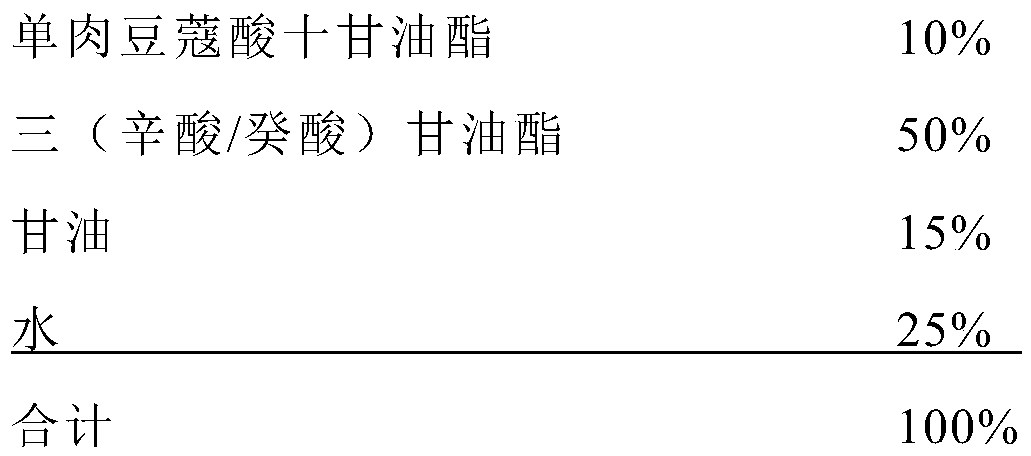

[0102] In addition, the preparation method and composition of the emulsion used are as follows. The prepared emulsions A1 to A5 were mixed in the amounts shown in the table.

[0103]

[0104] An O / W type emulsion of the following composition was prepared by the following method. In addition, stirring using a homomixer uses a well-known high-pressure homogenizer (pressure condition 30-100 MPa), and the operation of pou...

Embodiment 19~24

[0185] The liquid oral compositions (mouthwashes) of Examples 19 to 24 shown in Table 5 were prepared in the same manner as above, and the appearance stability (freeze recovery) during freezing and thawing, and the stability after oral use were evaluated in the same manner as above. Refreshing feeling, irritating feeling during use, biofilm bactericidal ability, and whether there is a pungent taste during use are evaluated by the following methods. Moreover, the presence or absence of a pungent taste was evaluated similarly to Example 10 shown in Table 3, and the result is described in Table 5 together with the above-mentioned result.

[0186] In addition, the spices a to f used in Examples 19 to 24 all contain clove oil and thyme oil, and the contents of clove oil and thyme oil in the compositions of each example are shown in Table 5.

[0187] (5) Evaluation method for presence or absence of pungent taste during use

[0188] 10 evaluators contained 10 mL of each liquid oral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com