Roller blind installation with side guides

A rolling shutter and equipment technology, applied in the field of rolling shutter equipment, can solve the problems of high wear and tear of the rolling shutter cloth, and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

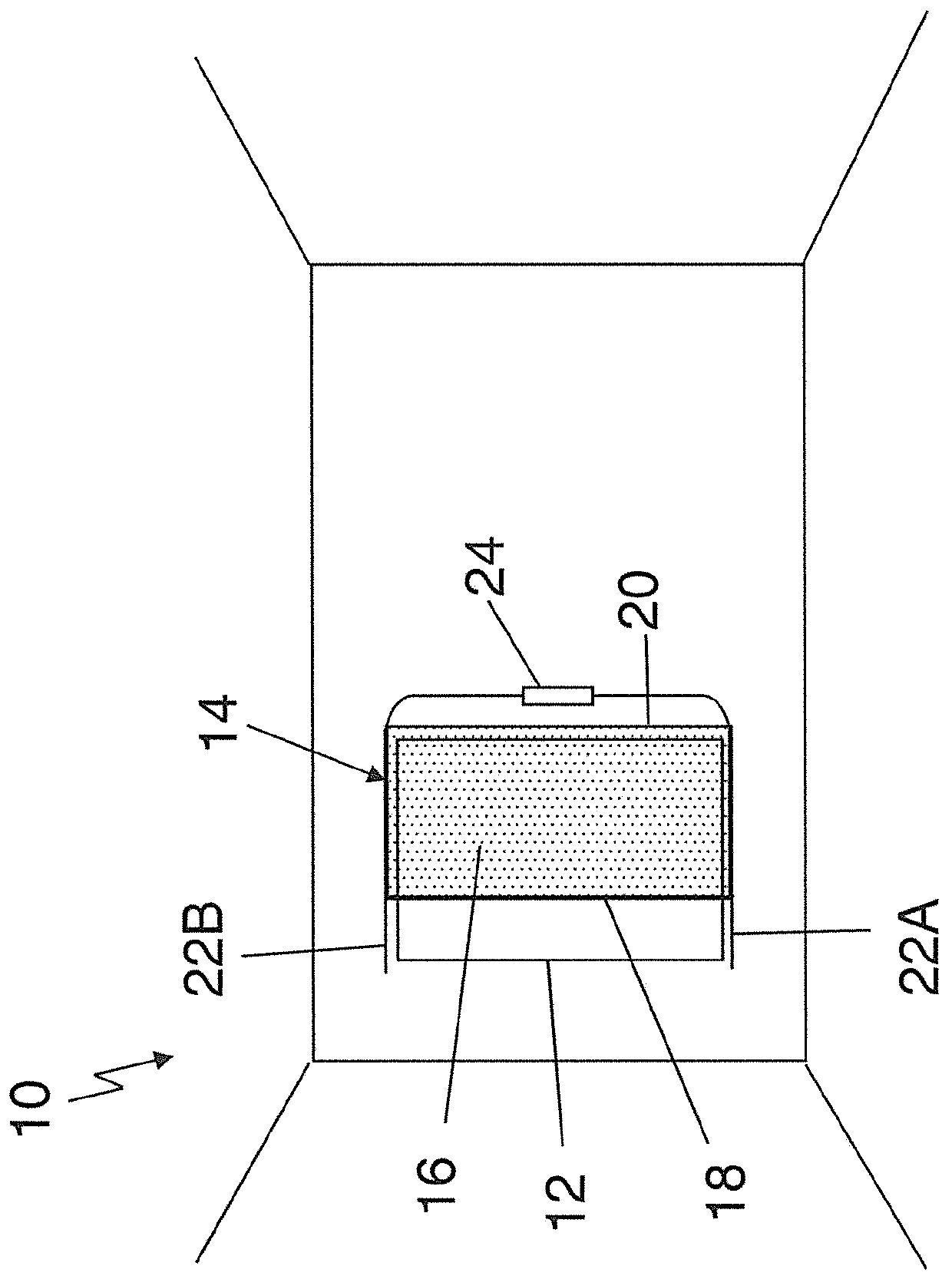

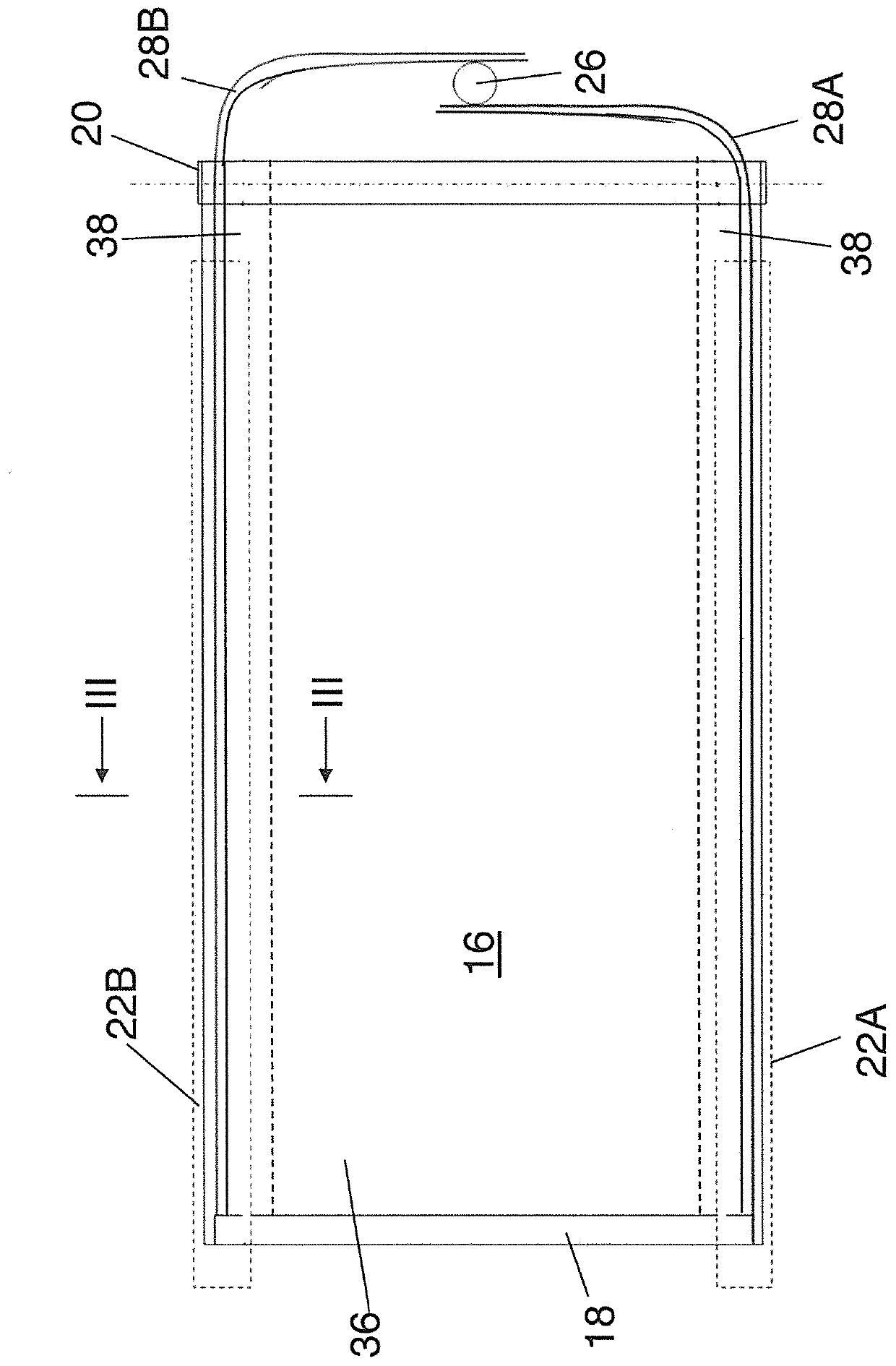

[0026] In the drawings, a vehicle roof 10 is shown, the vehicle roof additionally shows a passenger car that is not shown in more detail, and the vehicle roof has a roof opening 12, which can be modified by The transparent cover member shown in detail is closed or at least partially uncovered, and the vehicle roof relates to a roof opening system.

[0027] In order to shield the roof opening 12, the vehicle roof 10 includes a roller blind device 14 including a roller blind screen 16 made of fabric, which can be folded or wound accordingly.

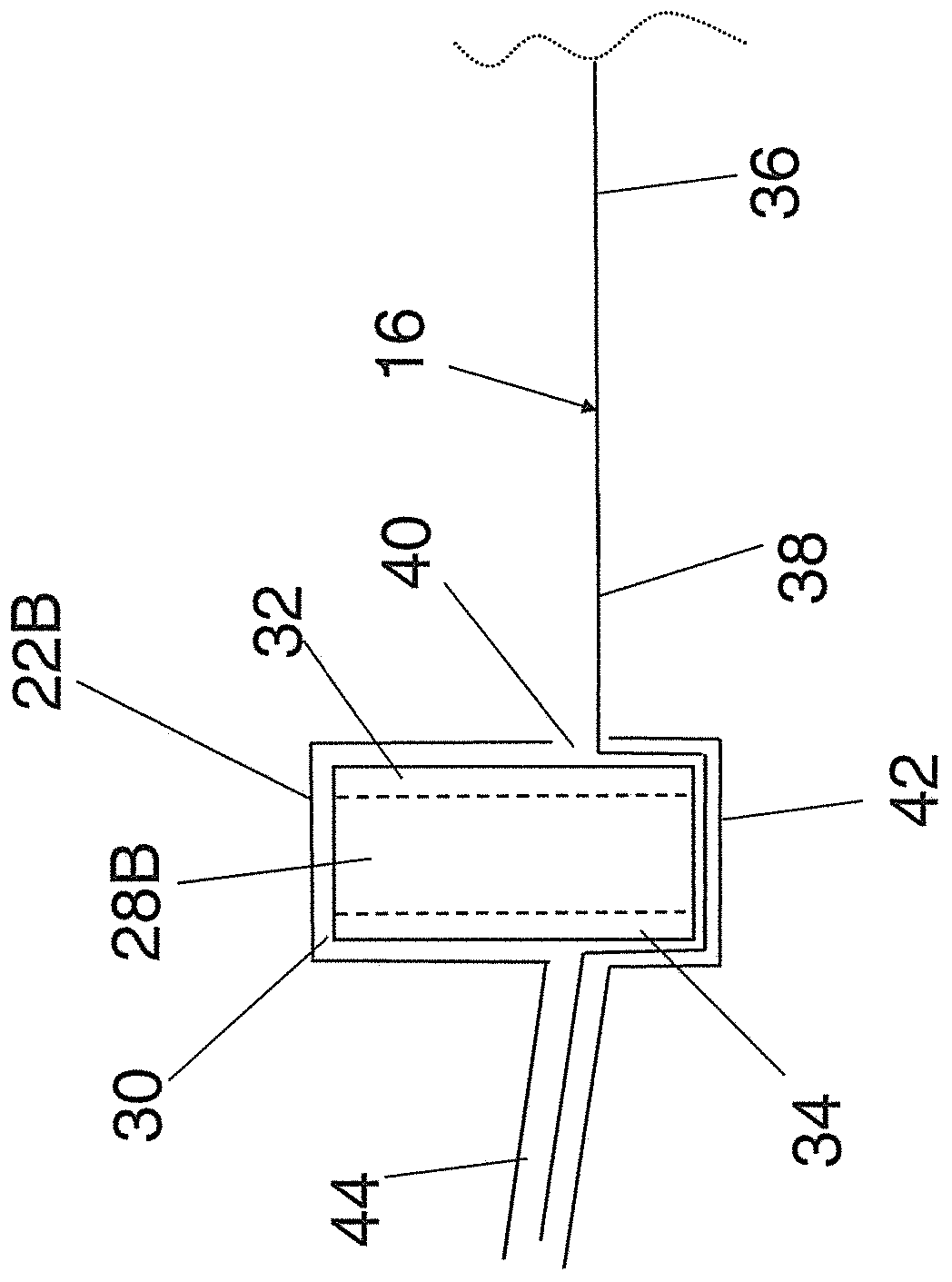

[0028] The roller blind fabric 16 has a tension bow 18 extending in the transverse direction of the vehicle on its free end side. The roller blind fabric 16 is fastened to a winding shaft 20 extending in the transverse direction of the vehicle at its edge facing away from the tension bow 18. The winding shaft 20 includes a winding tube which is mounted so as to be rotatable and which is pretensioned in the winding direction of the roller blind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com