Device on a carder for filling a round can with sliver, e.g. cotton, man-made fibers or the like

A chemical fiber and fiber sliver technology is applied in the field of equipment used in carding machines for filling circular cans with fiber sliver, such as cotton, chemical fibers or the like, and can solve difficult matching, high weight of circular cans, Influence and other problems, to achieve the effect of reducing replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

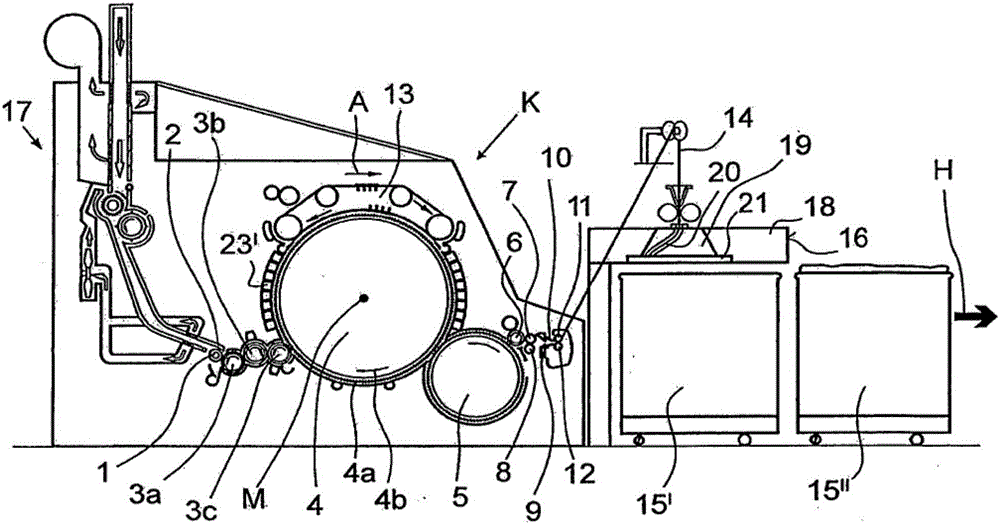

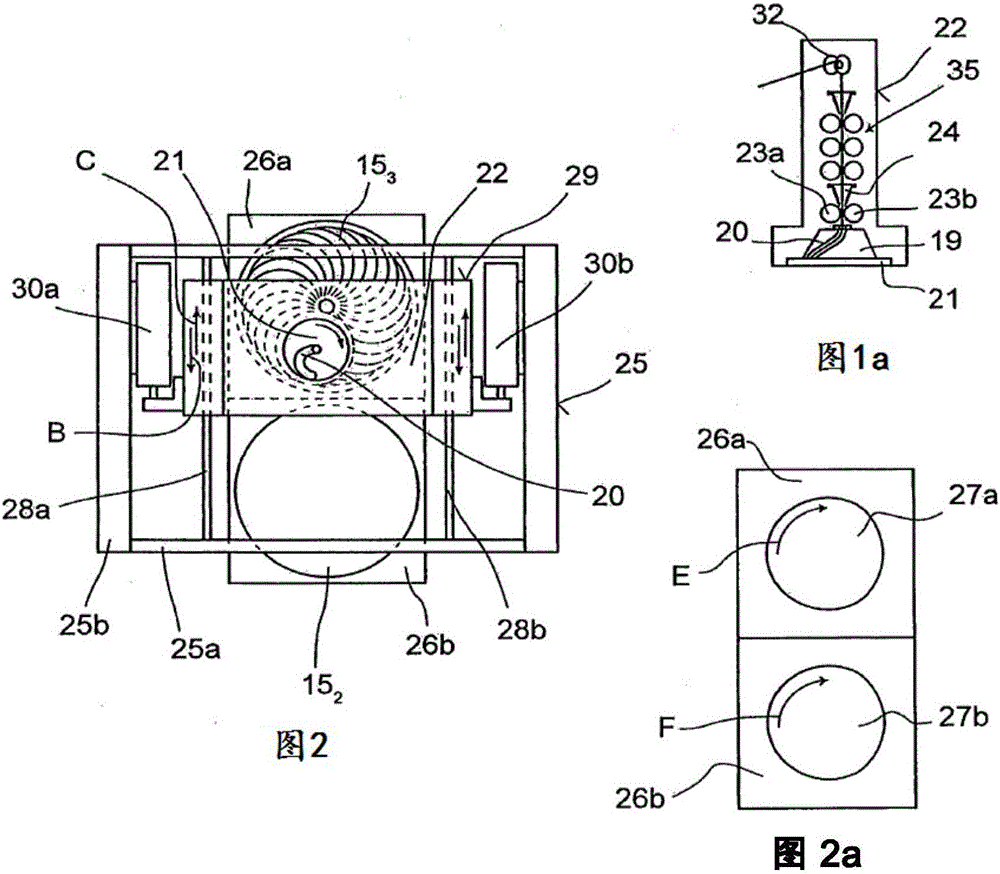

[0028] figure 1 Shown is a card K, for example a card TC from Truetzschler, which has a feed roll 1, a feed table (Speisetisch) 2, licker-in rolls 3a, 3b, 3c, cylinders 4, doffers 5, Stripping rolls 6, squeeze rolls (Quetschwalzen) 7, 8, web forming guide elements (Vliesleitelement) 9, web hopper 10, take-off rolls 11, 12, revolving flats 13 with flat deflection rollers and flat bar , bar can 15 and coiler 16. The direction of rotation of the rollers is shown with curved arrows. Let M represent the center point (axis) of the drum 4 . 4a indicates the card clothing and 4b indicates the direction of rotation of the cylinder 4 . Arrow A indicates the working direction of the card K. Upstream of the card K, a cotton feed collection box device (Flockenspeiservorrichtung) 17 is arranged. A stacking head 19 is rotatably mounted in the stacking flat disk 18 . The stacking head 19 comprises a sliver channel 20 with an inlet and an outlet for the fiber sliver and a rotating disk 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com