Sealed-type electric compressor

An electric compressor, airtight technology, applied in the direction of machine/engine, liquid fuel engine, mechanical equipment, etc., can solve the problem of difficult to reduce motor noise, high noise, etc., to reduce iron loss, reduce radiation noise, ease burning and embedding effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

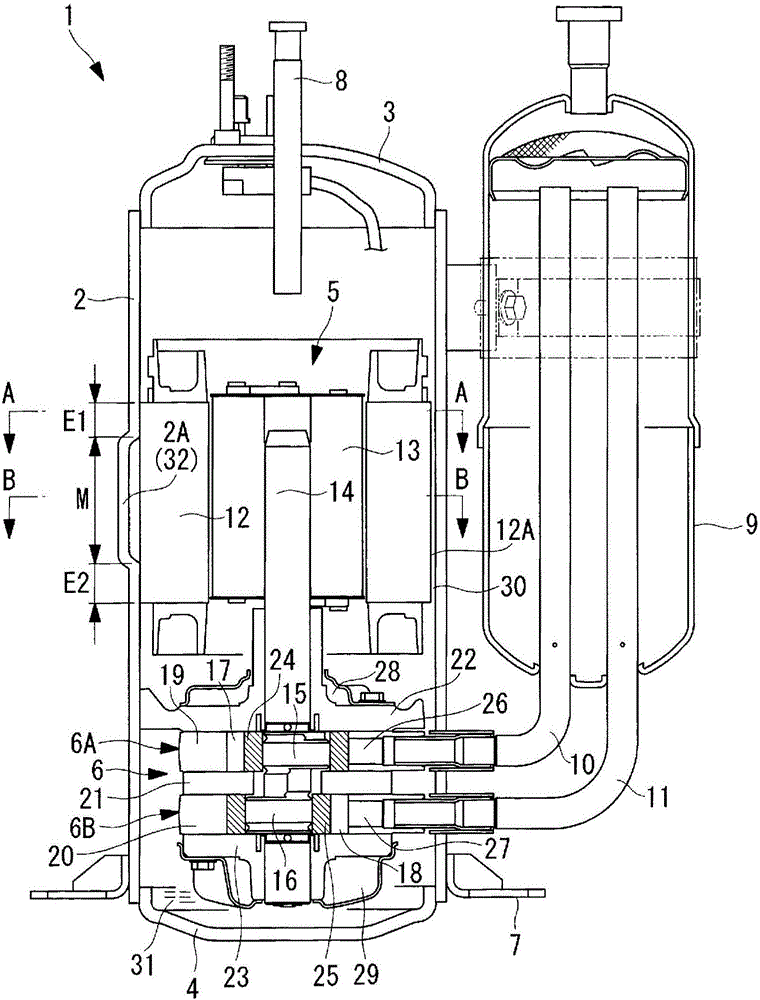

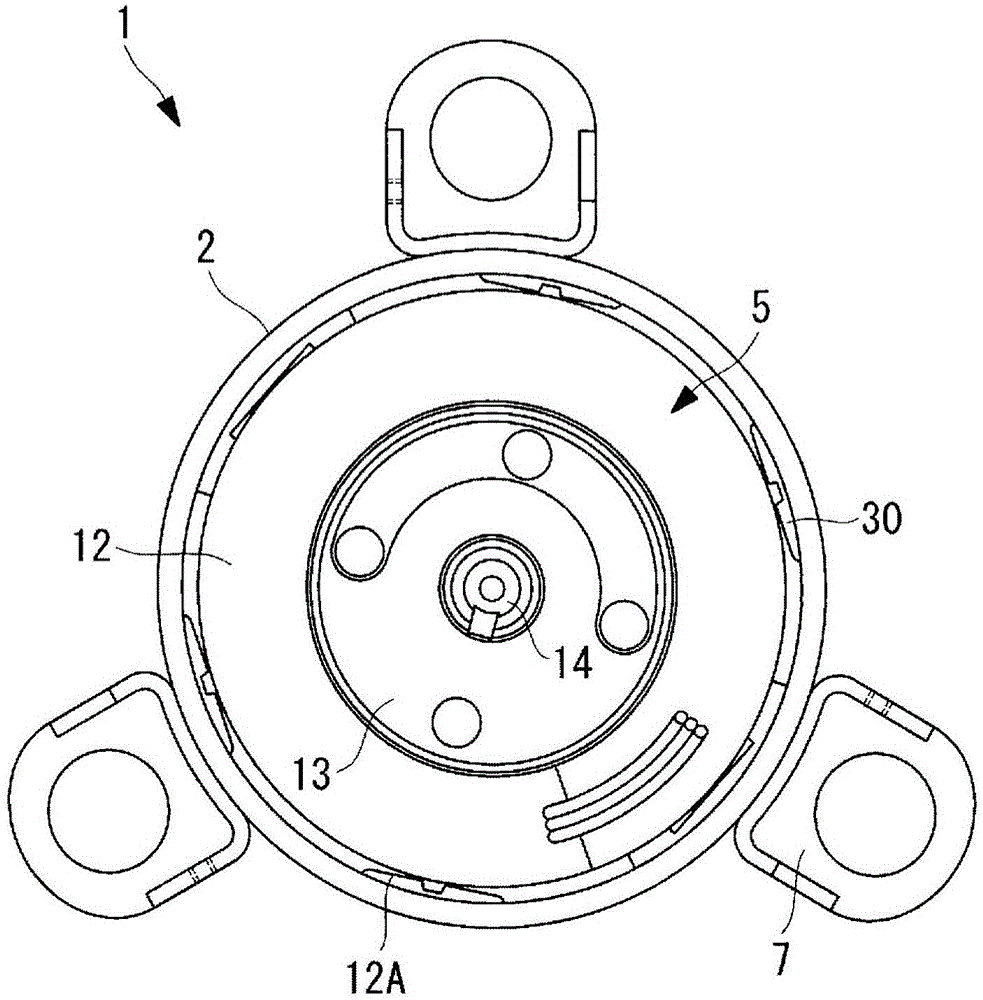

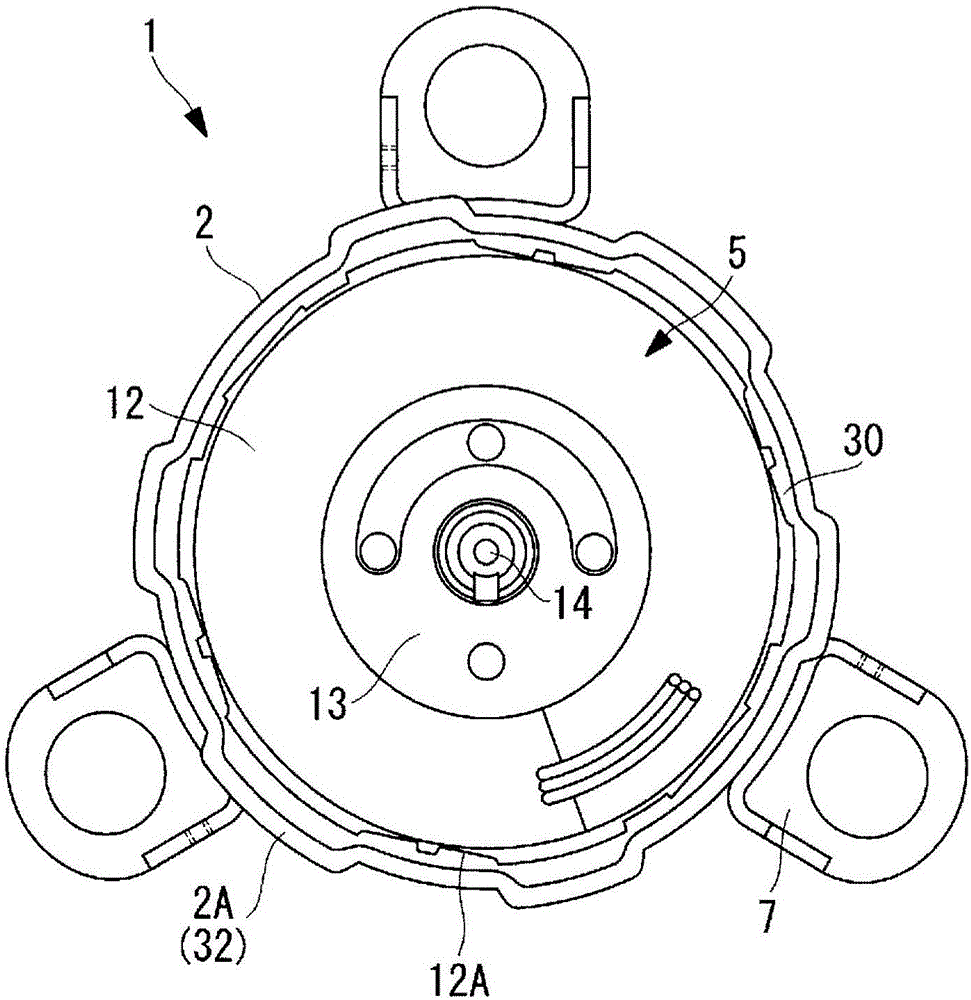

[0026] Below, refer to Figure 1 to Figure 3 , the embodiments according to the present invention will be described.

[0027] figure 1 shows a longitudinal sectional view of a hermetic electric compressor according to an embodiment of the present invention, figure 2 A schematic diagram of its A-A cross-section is shown in image 3 A schematic diagram of its B-B cross-section is shown in .

[0028] As the hermetic electric compressor 1 according to the present embodiment, a multi-cylinder rotary compressor is exemplified, but of course it is not limited thereto. The hermetic electric compressor 1 is provided with a cylindrical housing 2 whose upper and lower parts are sealed by cover plates 3 and 4, and is configured such that an electric motor 5 is provided at an upper part thereof, and an electric motor 5 is provided at a lower part thereof. 5 Driven compression mechanism (rotary compression mechanism) 6.

[0029] On the outer periphery of the lower part of the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com