Cleaning machine with functions of steam and dust absorption

A cleaning machine and steam technology, which is applied to vacuum cleaners, cleaning machines, carpet cleaning, etc., can solve the problems of less steam cleaning machines, inconvenient users, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

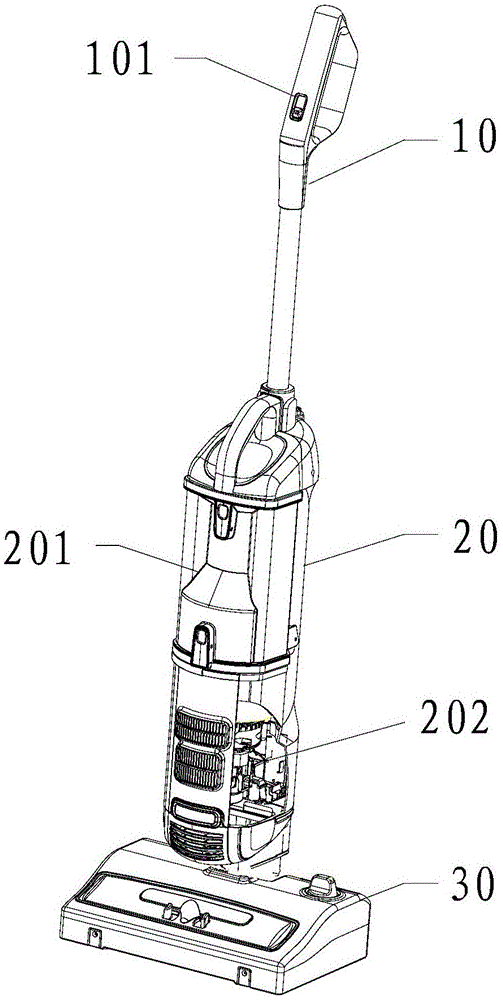

[0023] figure 1 It is a schematic structural diagram of a steam cleaning machine according to an embodiment of the present invention. Such as figure 1 As shown, the steam cleaning machine includes a handle 10 , a body 20 and a floor brush 30 arranged sequentially from top to bottom. The button 101 provided on the handle 10 is electrically connected with the conversion control module (not shown in the figure) in the body 20, so as to control the steam cleaning machine in different working modes. A dust bucket 201 for storing dust and sewage is arranged inside the fuselage 20, and a main fan 202 for generating vacuum suction is arranged under the dust bucket 201, and the main fan 202 is electrically connected to the conversion control module. The present invention does not limit the position of the button 101 , and the button 101 can also be arranged on the body 20 or the floor brush 30 .

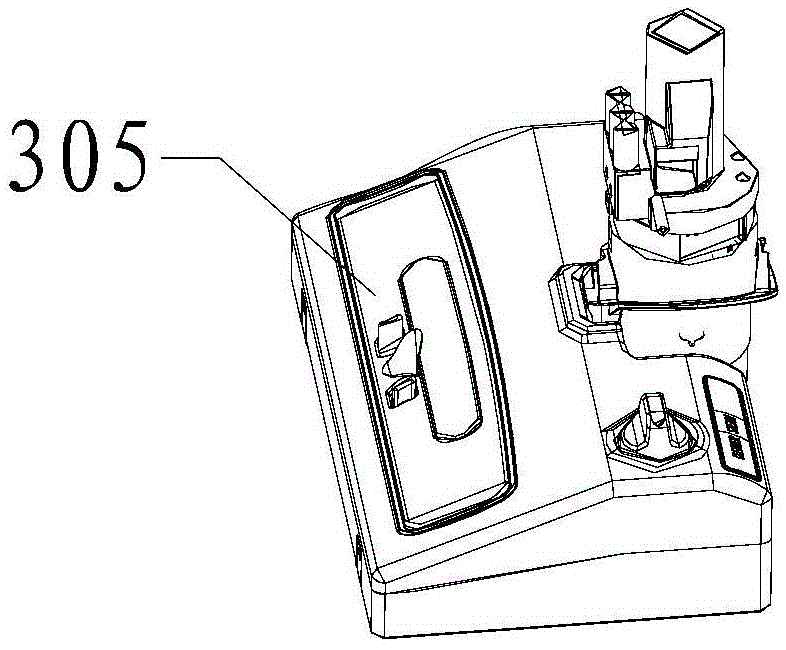

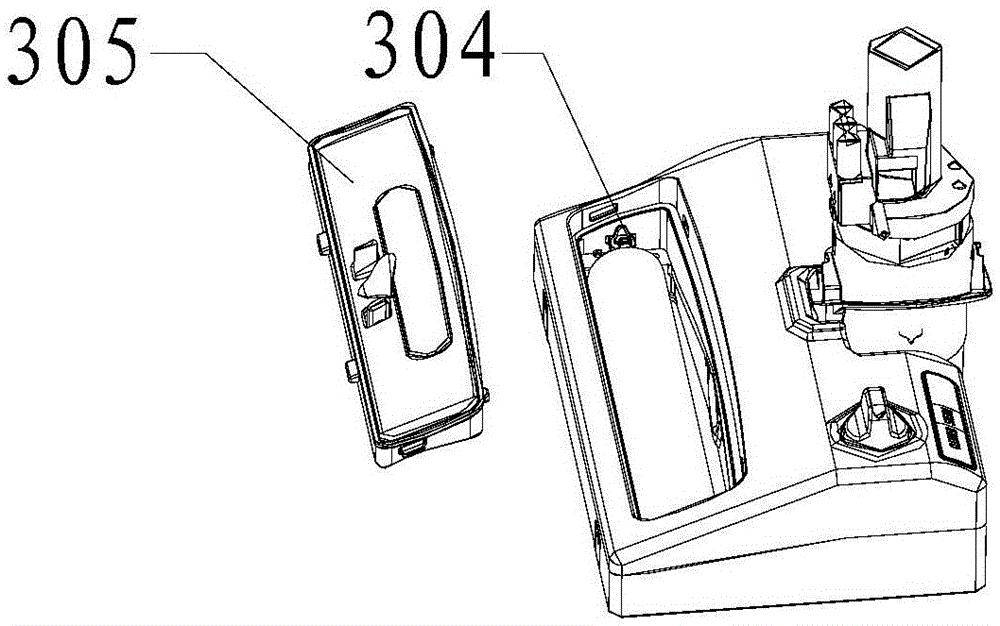

[0024] Figure 2A It is a schematic diagram of a ground brush in a normal state accor...

Embodiment 2

[0036] Compared with the first embodiment, the present embodiment differs in that the water tank, the water pump and the steam generator are located in the fuselage, and the other structures are the same, and the working principle is the same, which will not be repeated here.

[0037] To sum up, the present invention provides a steam vacuum cleaning machine, the steam vacuum cleaning machine has cleaning function, sewage recovery function and steam function at the same time, and the three functions are concentrated on one floor brush, and no cleaning is required during cleaning. The replacement of the floor brush simplifies the user's operation, and at the same time, compared with the two types of floor brush cleaning appliances currently on the market, the cost is reduced to some extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com