Aluminium trichloride reactor

A technology of aluminum trichloride and reactor, which is applied in the direction of aluminum chloride, aluminum halide, chemical instruments and methods, etc., can solve the problems of large fluctuations in the amount of aluminum powder, uneven distribution of aluminum powder, unfavorable reactions, etc., and achieve improvement The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below.

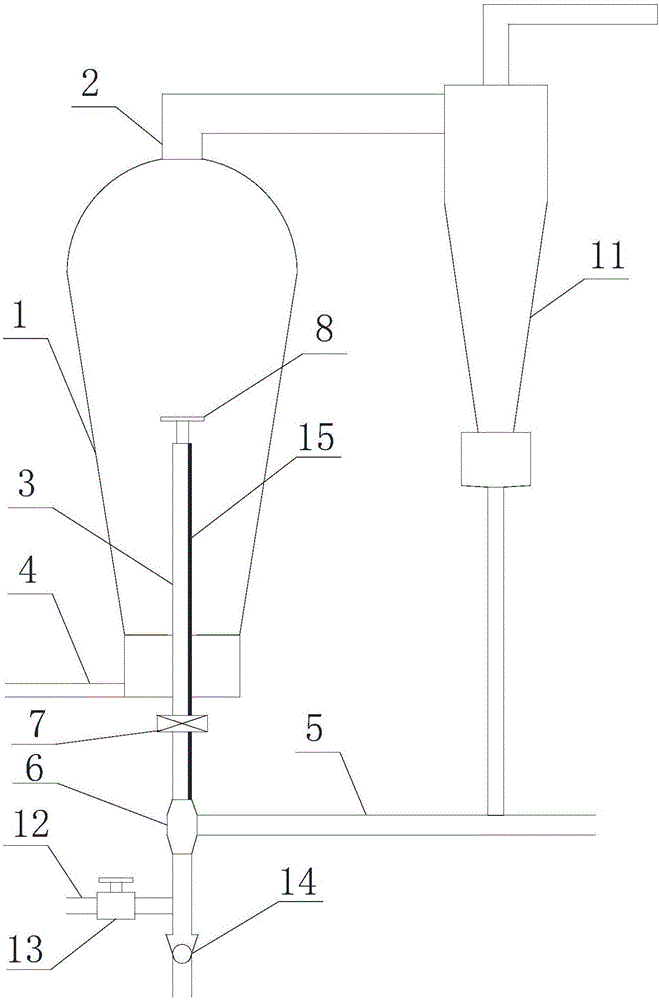

[0017] The aluminum trichloride reactor disclosed by the present invention comprises a reaction chamber 1, a discharge port 2, a first feeding pipe 3 for feeding chlorine gas and aluminum powder and a second feeding pipe for feeding titanium tetrachloride gas. Feeding pipe 4, the first feeding pipe 3 is vertically arranged at the center of the bottom of the reaction chamber 1, and the top of the first feeding pipe 3 extends to the middle of the reaction chamber 1, and the lower part extends out of the reaction chamber 1, so The lower part of the first feeding pipe 3 is connected with an aluminum powder adding pipe 5 , the second feeding pipe 4 communicates with the bottom of the reaction chamber 1 , and the outlet 2 is arranged at the top of the reaction chamber 1 .

[0018] When the aluminum trichloride reactor is in operation, the aluminum powder is first added to the first feed pipe 3 through the aluminum powder add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com