Thermo-sensitive magnetic recording paper with white layer

A white layer, recording paper technology, applied in coating, paper, papermaking and other directions, to achieve the effect of adding more value, broadening the scope of use, and improving the effect of color printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

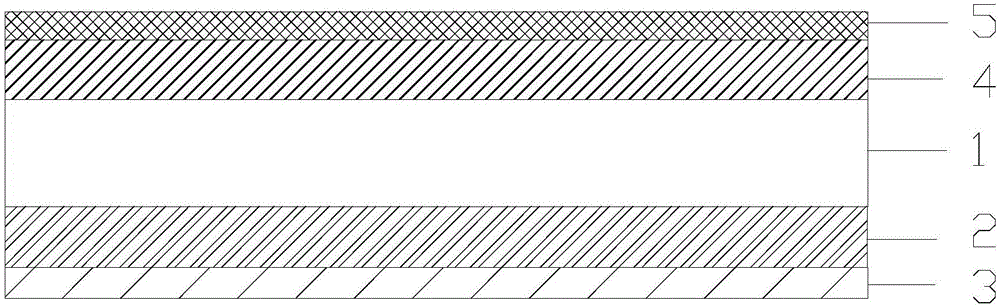

Image

Examples

Embodiment 1

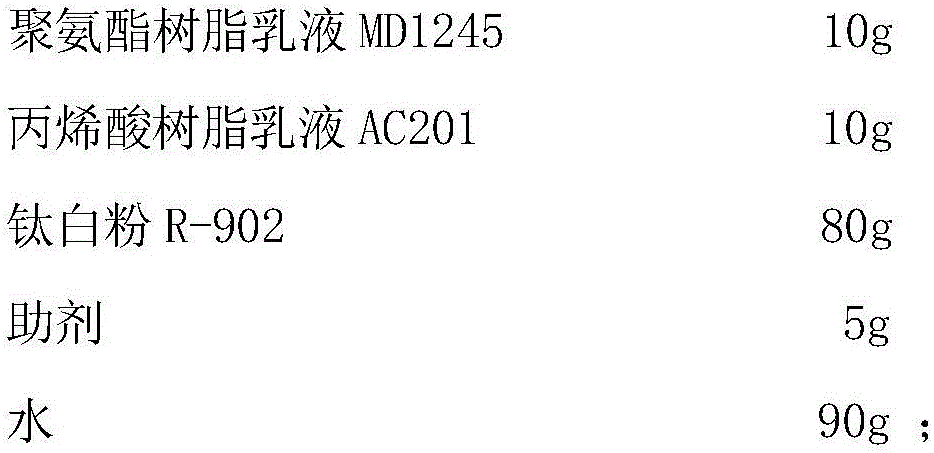

[0039] First prepare the white layer slurry, and its proportioning ratio is as follows:

[0040]

[0041] Dissolve and mix water, additives, polyurethane resin emulsion and acrylic resin emulsion in the stirring and dissolving tank evenly, put them into the dispersion tank, add titanium dioxide, disperse for 30-50 minutes, and then pass through the sand mill for 1-5 times. , discharge the slurry for coating the white layer.

[0042] Coat a magnetic layer on a 200-micron paper substrate, and then apply a white layer with a thickness of 6 μm on the magnetic layer by extrusion coating, then coat a heat-sensitive layer on the other side of the paper substrate, and then coat the heat-sensitive layer on the other side of the paper substrate. A heat-sensitive protective layer is coated on the layer, and a heat-sensitive magnetic recording paper with a white layer is prepared for performance testing.

Embodiment 2

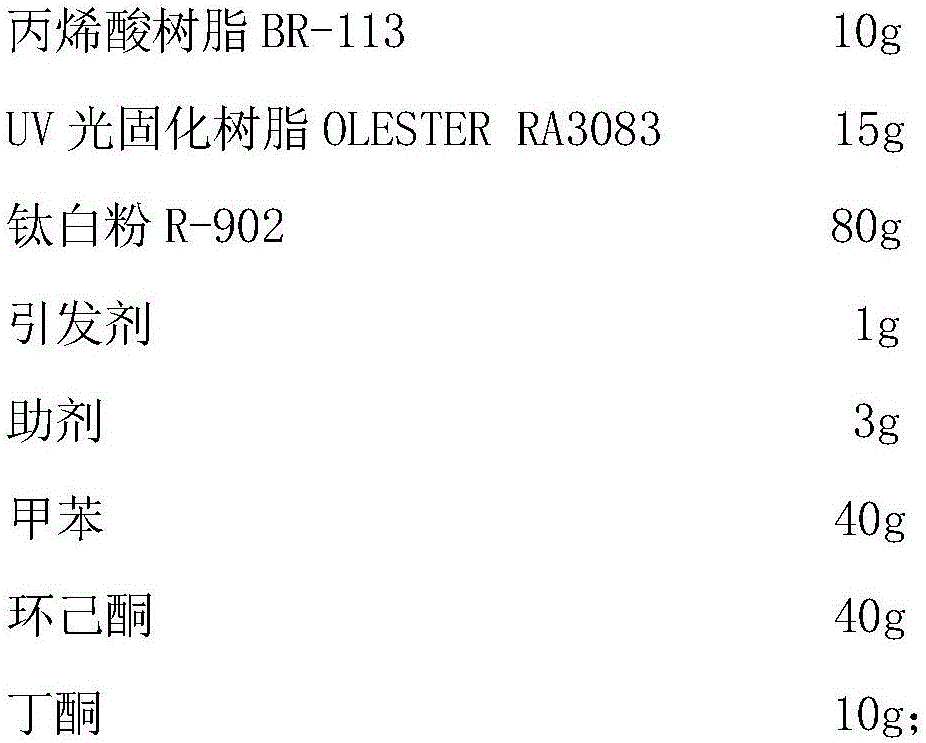

[0044] First prepare the white layer slurry, and its proportioning ratio is as follows:

[0045]

[0046] Dissolve the mixed solvent, additives, acrylic resin and UV photocurable resin in the stirring and dissolving tank and mix evenly, then put it into the dispersion tank, add titanium dioxide, disperse for 30-50 minutes, and then pass through the sand mill for 1-5 times Finally, put the material into the stirring tank, add the initiator dissolved in the solvent, stir and mix for 60-90 minutes, and release the slurry for coating the white layer.

[0047]Coat a magnetic layer on a 200-micron paper substrate, and then coat a white layer with a thickness of 6 μm on the magnetic layer by anilox roller coating, and then coat a heat-sensitive layer on the other side of the paper substrate, and then heat A heat-sensitive protective layer is coated on the sensitive layer to prepare a heat-sensitive magnetic recording paper with a white layer for performance testing.

Embodiment 3

[0049] First prepare the white layer slurry, and its proportioning ratio is as follows:

[0050]

[0051] Dissolve the mixed solvent, additives, polyurethane resin and UV photocurable resin in the stirring and dissolving tank and mix evenly, then put it into the dispersion tank, add titanium dioxide, disperse for 30-50 minutes, and then pass through the sand mill for 1-5 times Finally, put the material into the stirring tank, add the initiator dissolved in the solvent, stir and mix for 60-90 minutes, and release the slurry for coating the white layer.

[0052] Coat the magnetic layer on the 200 micron paper substrate, then coat the heat-sensitive layer on the other side of the paper substrate, then coat the heat-sensitive protective layer on the heat-sensitive layer, and then coat the magnetic layer with a wire bar A white layer with a thickness of 6 μm was coated to prepare a thermosensitive magnetic recording paper with a white layer, and a performance test was performed....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap