Cooling type oilless air compressor main body structure provided with piston for air inflow

An oil-free air compressor and heat-dissipating technology, which is applied to piston pumps, machines/engines, mechanical equipment, etc., can solve the problems of high temperature and large mutual influence of compression cylinders, and achieve good heat dissipation and not easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

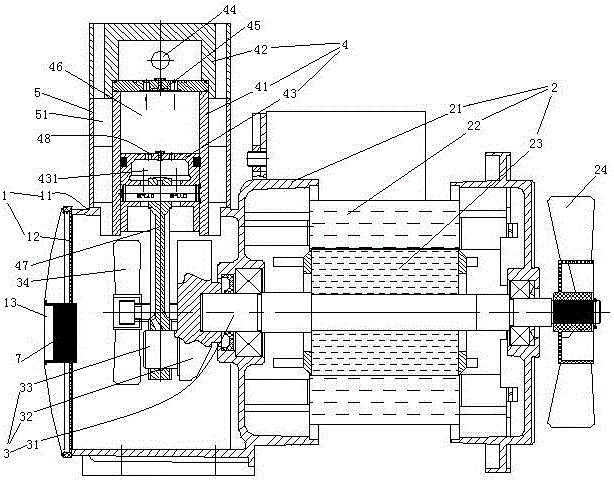

[0041] Embodiment one, see figure 1 , a piston intake and heat dissipation type oil-free air compressor host structure, including a crankcase 1, a motor 2, a crankshaft 3 and a compression cylinder 4.

[0042] The crankcase 1 includes a case body 11 and a side cover 12 . The side cover 12 is provided with an air inlet 13 . The air inlet 13 is provided with a filter 7 . Filter 7 is an existing air filter element.

[0043] The motor 2 includes a motor housing 21 , a stator 22 and a rotor 23 . The motor casing 21 is fixedly connected with the box body 11 . The stator 22 is fixed inside the motor housing 21 . The rotor 23 is located within the stator 22 . One end of the rotating shaft of the rotor 23 is provided with a cooling fan 24 .

[0044] The crankshaft 3 is located in the crankcase 1 . The crankshaft 3 includes a main journal 31 and a pin journal 33 connected together by a crank arm 32 . The main journal 31 is rotatably supported on the crankcase 1 through bearings...

Embodiment 2

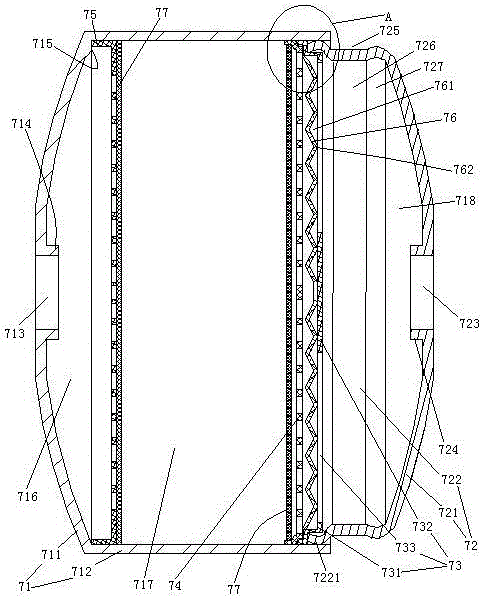

[0047] Embodiment two, the difference with embodiment one is:

[0048] see figure 2 , also includes mount 6. Both the crankcase 1 and the motor 3 are fixed on the mounting base 6 through bolts 61 and nuts 8 . The mounting base 6 is provided with a vibration isolation base 9 . The vibration isolation seat 9 includes a vertical damping oil cylinder 91 and a shock absorbing spring 92 sleeved on the damping oil cylinder. The damping oil cylinder 91 includes a damping oil cylinder body 911 . The damping oil cylinder body 911 is connected with the mounting seat 6 together. A first piston 912 is disposed inside the damping oil cylinder body 911 . The first piston 912 is connected to the supporting seat 93 through the piston rod 913 . One end of the damping spring 92 is affixed together with the piston rod 913, and the other end is affixed together with the cylinder body 911 of the damping oil cylinder.

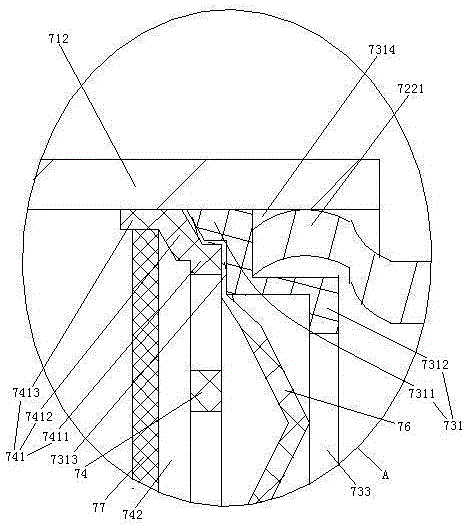

[0049] see image 3 , The second piston 914 and the separation plate 94...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com