Horizontal decanter centrifuge

A decanter centrifuge and horizontal screw technology, applied in the field of centrifuges, can solve problems such as damage to sealing rings and bearings, damage to the inner wall of the drum, and reduction of solid particle cutting, so as to achieve smooth transmission, prolong service life, and reduce volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

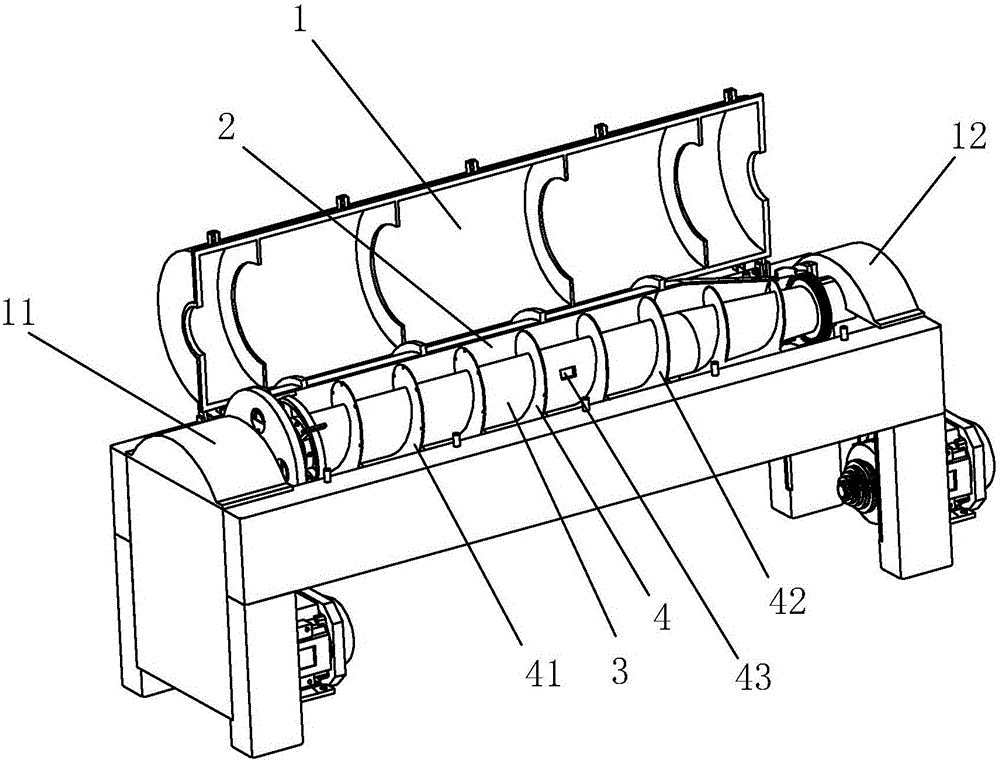

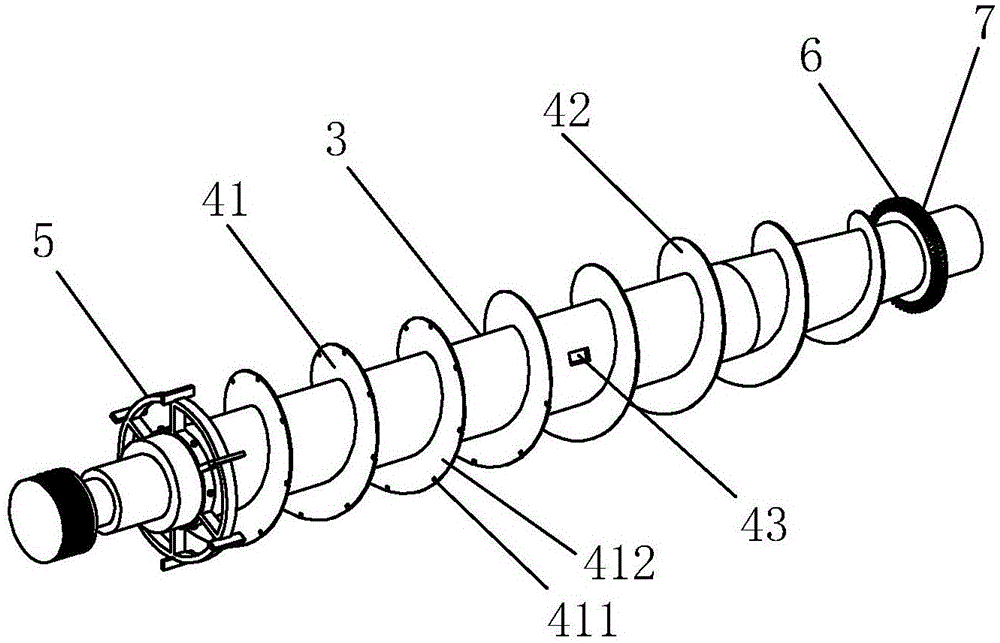

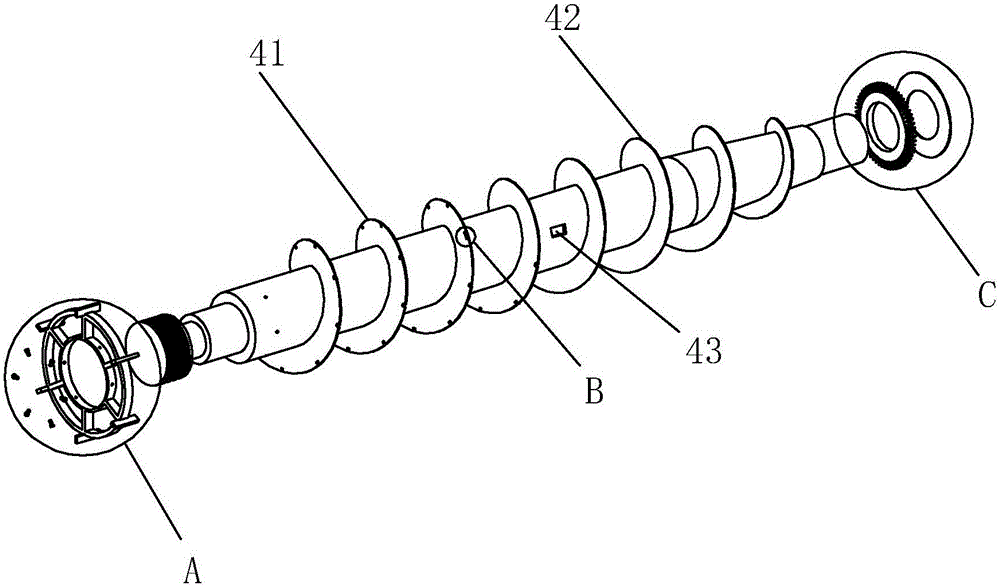

[0026] Embodiment: A horizontal screw discharge sedimentation centrifuge, including a shell 1, a screw pusher 3, a differential and a bearing seat, the screw pusher 3 includes a spiral blade 4, and the end of the screw pusher extends to the shell 1 outside and connected to the differential, a drum 2 is provided outside the screw propeller, a separation chamber is formed between the drum 2 and the inner wall of the shell 1, and an outer feed port and a solid phase are provided at the small diameter end 12 of the drum 2 The discharge port is provided with a liquid phase outlet at the large-diameter end 11 of the housing 1, the end of the helical blade 4 close to the small-diameter end 12 is the pushing end 42, and the end of the helical blade 4 close to the large-diameter end 11 is the cutting end 41, An inner outlet 43 is provided between the pushing end 42 and the cutting end 41, and the helical blade 4 is positioned at the cutting end 41 and is provided with several grooves 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com