Multisource-control spraying method based on cloud server and multisource-control spraying system

A multi-source control, cloud server technology, applied in the direction of injection devices, etc., can solve the problems of increasing engineering costs, waste of water resources, waste of water sources, etc., and achieve the effect of reducing the probability of high temperature heatstroke, efficient dust removal and noise reduction, and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

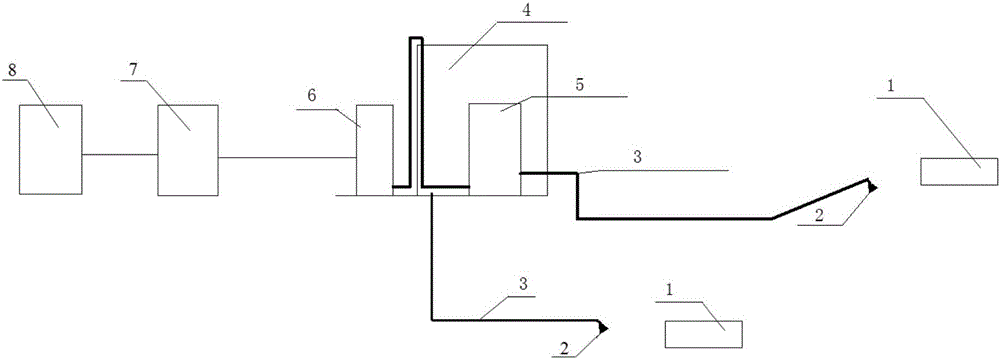

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

[0029] The invention provides a cloud server-based multi-source control spraying method, comprising the following steps:

[0030] (1) Set a group of multi-source sensors at different positions on the construction site, each multi-source sensor is equipped with a sprinkler connected to the water source, and each multi-source sensor collects the sound source signal, the seismic source signal and the dust source signal in real time;

[0031] (2) The multi-source sensor sends the sound source signal, vibration source signal and dust source signal to the control unit;

[0032] (3) The control unit uploads the signals collected by the multi-source sensors of the construction site to the cloud server at the same time; the cloud server collects the data uploaded by different construction sites and transmits them to the remote monitoring terminal;

[0033] (4) The control unit ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap