Automatic switch assembling machine

An automatic assembly machine and switch technology, applied in the direction of assembly machine, metal processing, metal processing equipment, etc., can solve problems such as the degree of automation of assembly that affects processing efficiency, the limited number and type of assembly stations, and the inability to automatically control the assembly process. The effect of improving stability and reliability, optional reinforcement, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

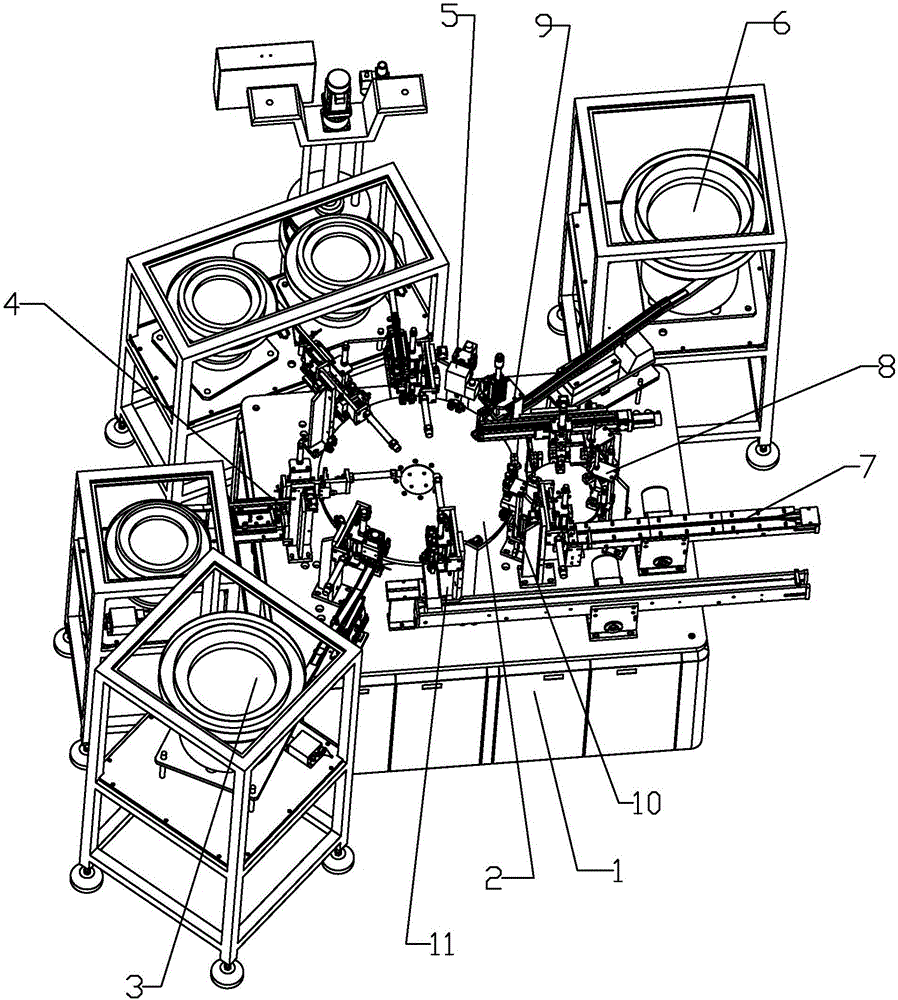

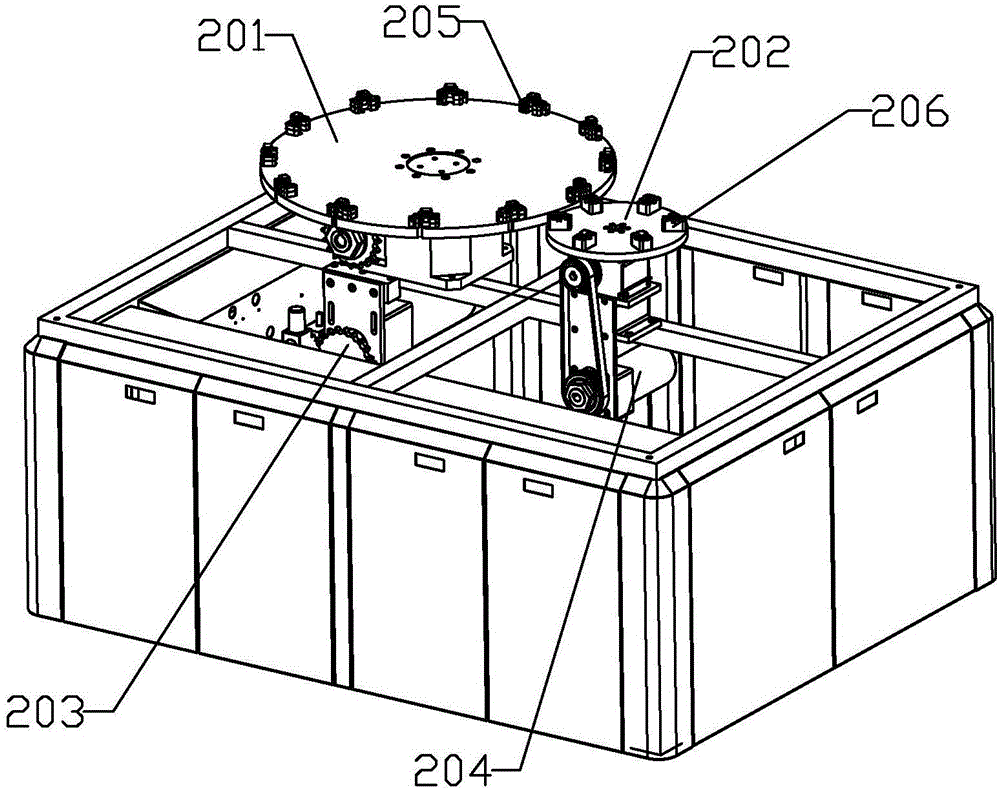

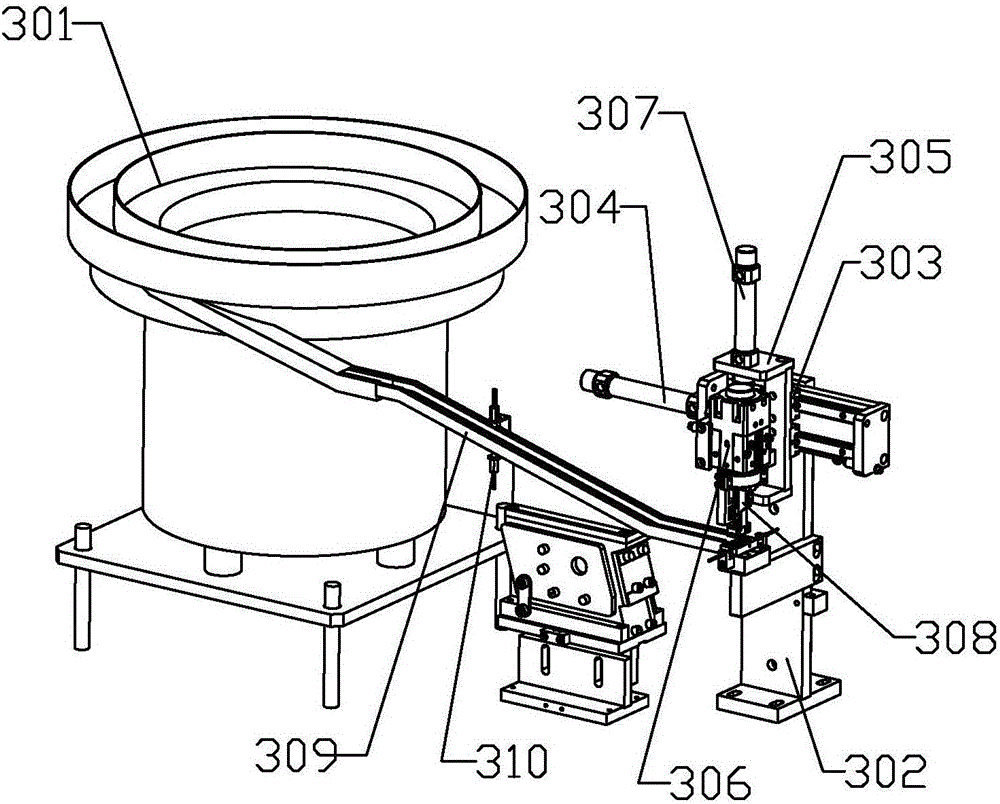

[0033] According to attached figure 1 As shown, the switch automatic assembly machine of the present invention mainly includes a frame 1, a circuit controller, a double turntable feeding mechanism 2, a base assembly mechanism 3, a sheet component assembly mechanism 4, an oil supply mechanism 5, a bracket assembly mechanism 6, and a button supply mechanism. Material mechanism 7, button component pressing mechanism 8, button sorting mechanism 9, switch detection mechanism 10 and switch discharging mechanism 11. Among them, the circuit controller can be set in the frame 1, and can also be set on the frame 1, and the double turntable feeding mechanism 2, the base assembly mechanism 3, the sheet component assembly mechanism 4, the oil supply mechanism 5, and the bracket assembly mechanism 6 , button feeding mechanism 7, button component pressing mechanism 8, button sorting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com